A sewage treatment plant sludge reduction and recycling process

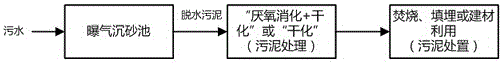

A technology of sewage treatment plant and treatment process, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, sludge treatment, etc., which can solve the problems affecting the promotion and application of sludge anaerobic digestion technology and the conversion rate of organic matter And problems such as low biogas yield and long sludge residence time, to achieve good sludge drying effect, realize sludge reduction, and save aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

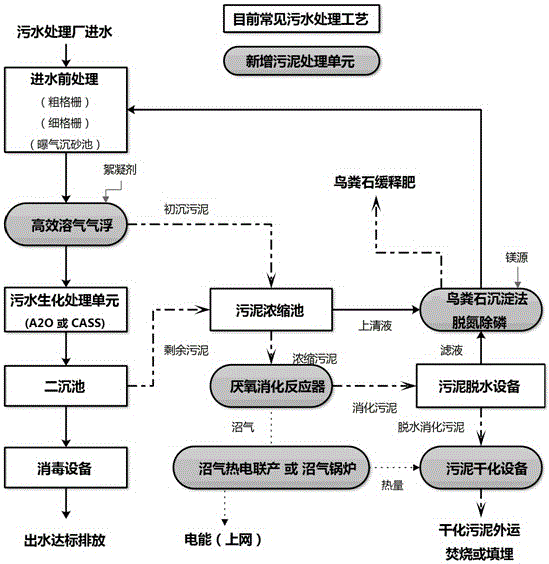

[0037] Such as figure 2 Shown in, the waste water treatment plant sludge reduction and recycling treatment process provided by the present invention comprises the following steps:

[0038] (1) After the sewage entering the sewage treatment plant is pretreated by coarse screens, fine screens and aeration grit chambers, it enters a rectangular high-efficiency pressurized dissolved air flotation device, and PAM flocculant (dosing amount 1mg / L), most of the suspended particles (SS) and some dissolved organic matter in the sewage are removed to form "primary sludge"; the test results show that in this process, 50%~70% of the suspended particles (SS) is removed, and the sewage treated by the high-efficiency dissolved air flotation device is respectively passed through the biochemical treatment unit (aerobic, A 2 O method), the secondary settling tank and disinfection treatment are discharged up to the standard. Since the air flotation unit removes 50%~70% of suspended particles (S...

Embodiment 2

[0042] Such as figure 2 Shown in, the waste water treatment plant sludge reduction and recycling treatment process provided by the present invention comprises the following steps:

[0043] (1) After the sewage entering the sewage treatment plant is pretreated by coarse screens, fine screens and aeration grit chambers, it enters the shallow high-efficiency dissolved air flotation device, and PAM flocculant (dosing amount 2mg / In the case of L), most of the suspended solids (SS) and part of the dissolved organic matter in the sewage are removed to form "primary sludge"; the test results show that during this process, 50% to 70% of the suspended solids (SS ) is removed, and the sewage treated by the high-efficiency dissolved air flotation device is discharged to the standard after the biochemical treatment unit (aerobic, CASS method), secondary sedimentation tank and disinfection treatment, because the air flotation unit removes 50%~70% of the sewage % of suspended particles (S...

Embodiment 3

[0047] The difference from Example 1 is that the biogas generated by the anaerobic digestion of the mixed sludge in step (2) is directly passed into the biogas boiler after dehydration, desulfurization and purification treatment to generate a heat source for sludge drying. Finally, the dried sludge obtained is transported to the landfill for landfill disposal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com