Fork truck transport machine in coal mine tunnel

A technology of coal mine roadway and conveyor, which is applied in the direction of lifting devices, etc., can solve the problems of affecting the work safety of workers, difficult operation, single function, etc., and achieve the effect of saving road cleaning time, reducing labor intensity and shortening service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

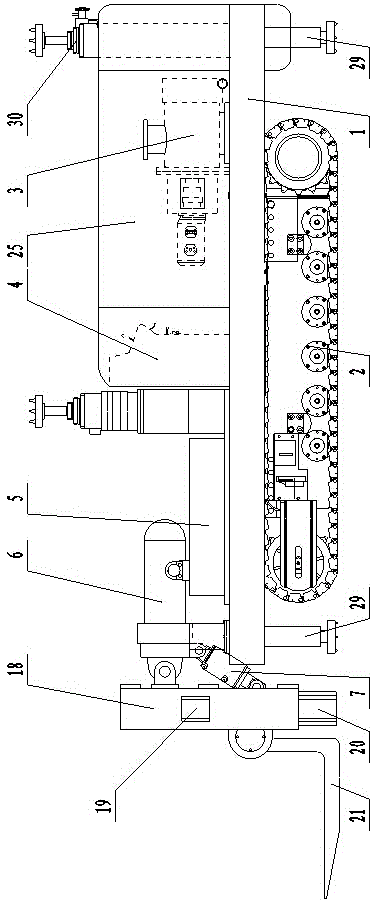

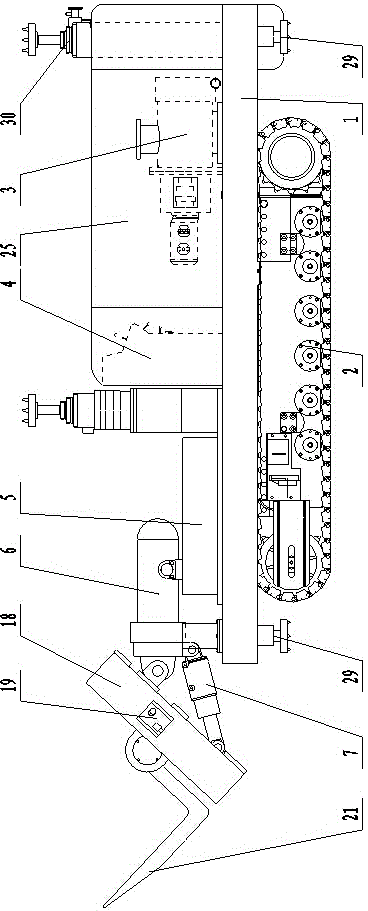

[0024] Such as Figure 1-3 As shown, the forklift transporter in the coal mine roadway of the present invention includes a frame 1, a running mechanism 2, an explosion-proof diesel engine 3, a hydraulic system, a console 4, a turntable 5 and forklift parts, and the bottom of the frame 1 is equipped with multiple groups of running mechanisms 2, The rear end of the forklift parts is fixedly installed on the front part of the frame 1 through the turntable 5, and the rear part of the frame 1 is equipped with an explosion-proof diesel engine 3 and a hydraulic system to provide power, and a console 4 and a driver's seat are also installed on the frame 1;

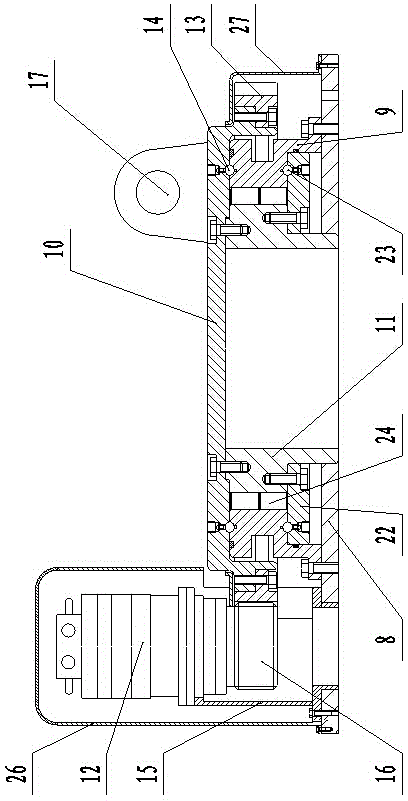

[0025] The structure of the turntable 5 includes a base 8, a turntable bracket 9, an upper turntable 10, an intermediate movable frame 11, a hydraulic motor 12 and a ring gear 13, the turntable support 9 is fixed on the base 8 by bolts, and the upper turntable 10 is an undercut The disc shape is movably buckled on the turntable su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com