Semiautomatic rice dumping-wrapping machine

A semi-automatic, rice dumpling machine technology, applied in the direction of wrapping objects, packaging/bundling items, multiple packages, etc., can solve the problems of poor bundling quality and low manual production efficiency, achieve uniform weight, solve low manual production efficiency, avoid Shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

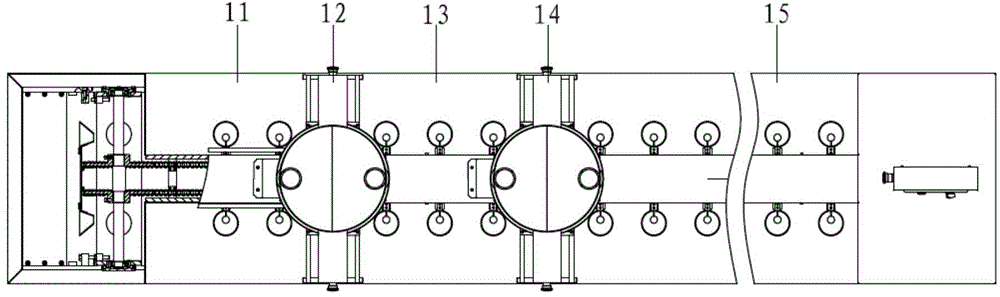

[0042] Such as figure 1 and figure 2 Shown, a kind of semi-automatic rice dumpling wrapping machine comprises frame 1, is provided with zong leaf mold conveying device in frame 1, and the transmission chain 3 of this zong leaf mold conveying device passes the working area of frame 1 top, and working area is along the The traveling direction of the conveying chain is divided into zong leaf placing position 11, primary rice filling position 12, stuffing filling position 13, secondary rice adding position 14 and unloading binding position 15. Zongye placement position 11, filling filling position 12 and unloading bundling position 13 are all manually operated, respectively placing Zongye in the Zongye mould, adding fillings and taking out Zongye for bundling. At the same time, adding rice position 12 and Quantitatively lower rice device is all installed in the secondary rice-adding position 14, is used for quantitatively lowering rice in the zongzi leaf mold 4.

[0043] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com