An outer mold for integral demoulding of concrete tapered rods

A tapered rod and concrete technology, applied in the direction of molds, etc., can solve the problems of low production efficiency, cumbersome procedures, and unsightly appearance, and achieve the effects of low cost, simple manufacture, and easy and quick demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

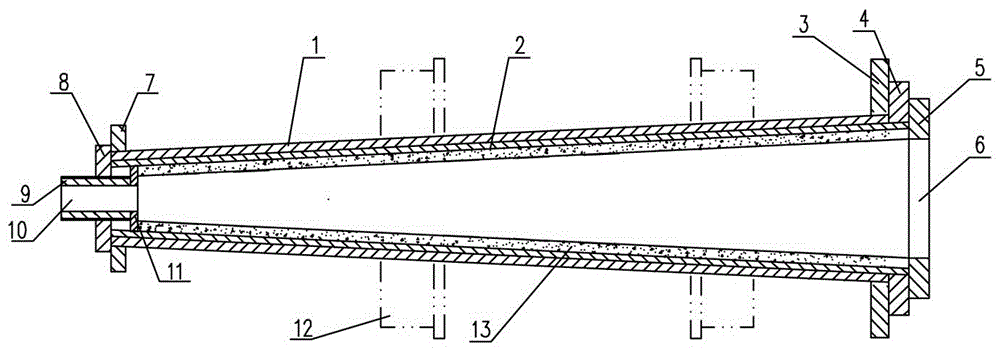

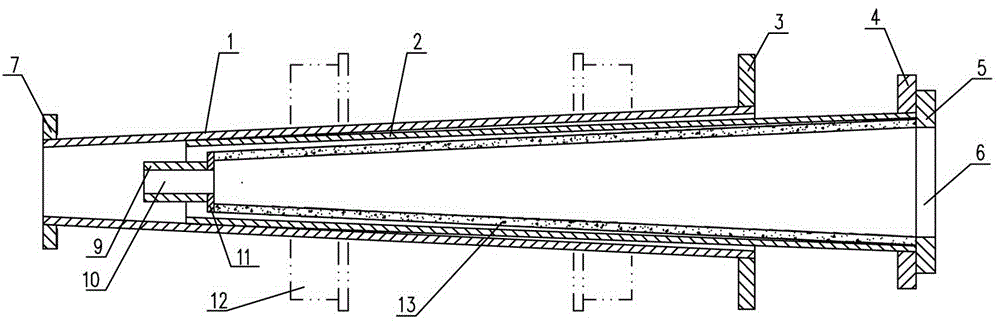

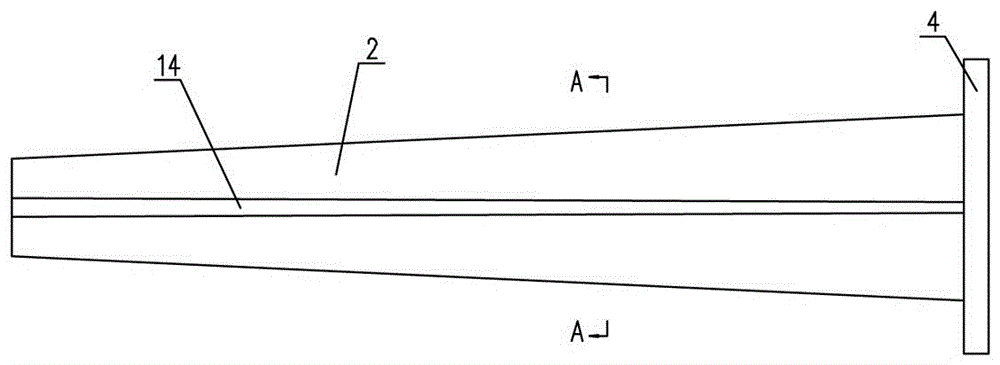

[0019] Such as figure 1 , 2 , Shown in 3 and 4, a kind of outer mold of concrete tapered rod integral demoulding of the present invention is characterized in that comprising outer mold main body and being located at the movement in the outer mold main body to help demoulding, described outer mold main body consists of Tapered sleeve 1, flange I3 fixedly connected with the large diameter end of the tapered sleeve 1, flange II7 fixedly connected with the small diameter end of the tapered sleeve 1 and the small end hanging on the flange II7 The rib plate assembly is composed of the moving demoulding aid consisting of a steel plate cone drum 2 with an opening slit 14 in the longitudinal direction, a flange III4 fixedly connected to the large diameter end of the steel plate cone drum 2 and abutting against the steel plate cone drum 2 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com