Automatic rotating welding device for pipeline

A technology of automatic rotation and welding device, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effect of improving work efficiency, ensuring accuracy and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

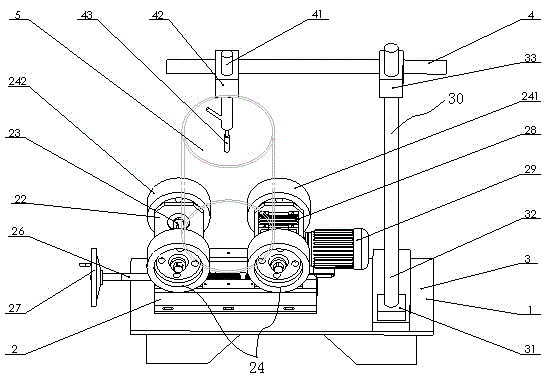

[0020] As an embodiment of the present invention, the automatic rotary welding device will be further described below in conjunction with the accompanying drawings.

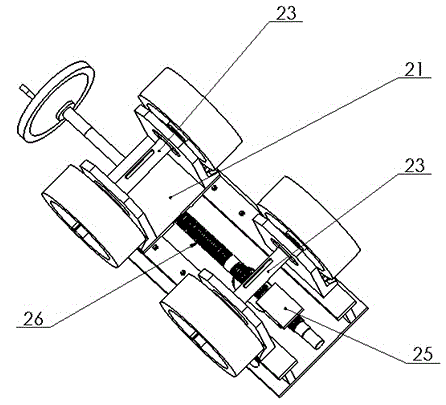

[0021] Such as figure 1 As shown, a pipeline automatic rotary welding device includes a workbench 1 and driving wheels 24 and welding torch brackets assembled at intervals on it. The driving wheels 24 are detachably connected to the driving wheel bracket 22 respectively. The driving wheel 241 and the driven wheel 242 are respectively connected by the driving wheel shaft 23 and installed on the driving wheel bracket 22. The driving wheel bracket 22 is respectively detachably connected to the driving base 2 through the driving slide plate 21 , and the driving slide plate 21 can move horizontally along the driving base 2 . The middle of the driving wheel shaft 23 of the driving wheel 241 is connected with the output end of the speed reducer 28 through a shaft coupling, and the speed reducer 28 is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com