A method for drying cigar leaf wrappers by threading needle ropes through tobacco ribs and binding rods

A technology for tying cigar leaves and rods, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of poor wrapper effect of H382 cigars, and achieve convenient access to air-cured tobacco leaves, outstanding flavor, and improved air-curing The effect of grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

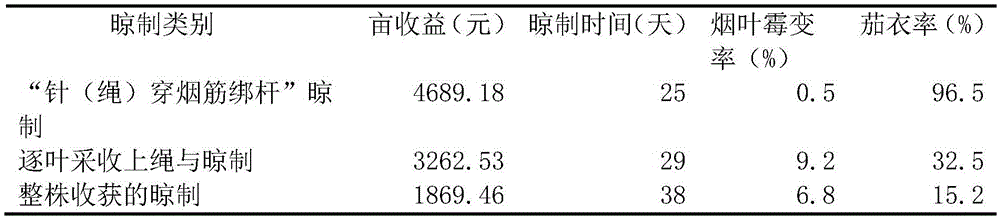

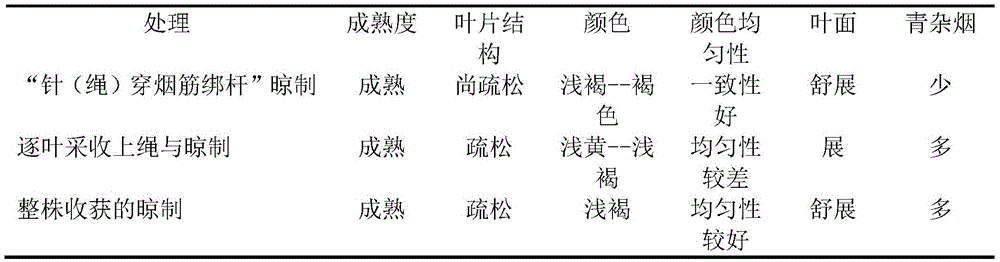

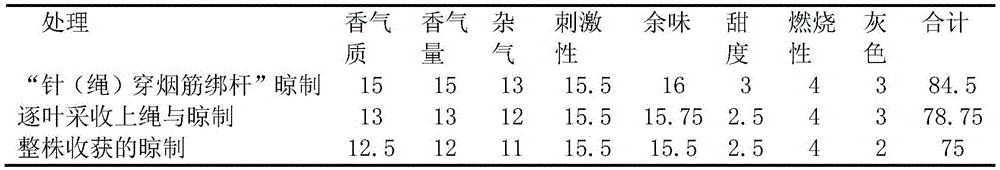

Embodiment 1

[0040] Embodiment 1: the method for airing the cigar tobacco leaf wrapper with a needle and rope through the tobacco ribs and binding rods of the present invention is characterized in that it includes the following steps: a. Airing room arrangement: the airing room for the cigar tobacco leaf wrapper is composed of a wall and a roof The main body of the airing room is equipped with a cigarette drying rack, the wall is equipped with a ventilation door and a roll-up moisturizing curtain, the wall is made of hollow bricks according to the flower wall, the cross section of the roof on the airing room body is triangular, and the roof of the roof The outer layer is made of high-strength greenhouse film, the middle layer is made of glass thermal insulation cotton, and the inner layer is made of 3-pin black sunshade net; the single building for drying cigar leaf wrappers is 3.9m long, 7.2m wide, and 5.1m high. Area 28.08m 2 , can be multiple buildings, preferably 5 buildings, with a ci...

Embodiment 2

[0047] Embodiment 2: The method for airing the cigar leaf wrapper with a needle rope through the tobacco tendon and binding rods of the present invention is characterized in that it includes the following steps: a. Airing room arrangement: the airing room for the cigar tobacco leaf wrapper is composed of a wall and a roof The main body of the airing room is equipped with a cigarette drying rack, the wall is equipped with a ventilation door and a roll-up moisturizing curtain, the wall is made of hollow bricks according to the flower wall, the cross section of the roof on the airing room body is triangular, and the roof of the roof The outer layer is made of high-strength greenhouse film, the middle layer is made of glass thermal insulation cotton, and the inner layer is made of 3-pin black sunshade net; the single building for drying cigar leaf wrappers is 3.9m long, 7.2m wide, and 5.1m high. Area 28.08m 2 , can be multiple buildings, preferably 5 buildings, with a cigarette ra...

Embodiment 3

[0054] Embodiment 3: the method for airing the cigar tobacco leaf wrapper with a needle rope through the tobacco tendon and binding rods of the present invention is characterized in that it includes the following steps: a. Airing room arrangement: the airing room for the cigar tobacco leaf wrapper is composed of a wall and a roof The main body of the airing room is equipped with a cigarette drying rack, the wall is equipped with a ventilation door and a roll-up moisturizing curtain, the wall is made of hollow bricks according to the flower wall, the cross section of the roof on the airing room body is triangular, and the roof of the roof The outer layer is made of high-strength greenhouse film, the middle layer is made of glass thermal insulation cotton, and the inner layer is made of 3-pin black sunshade net; the single building for drying cigar leaf wrappers is 3.9m long, 7.2m wide, and 5.1m high. Area 28.08m 2 , can be multiple buildings, preferably 5 buildings, with a ciga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com