Metal bipolar plate for fuel cell

A metal bipolar plate and fuel cell technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of complex stamping dies and increasing the thickness of metal double plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

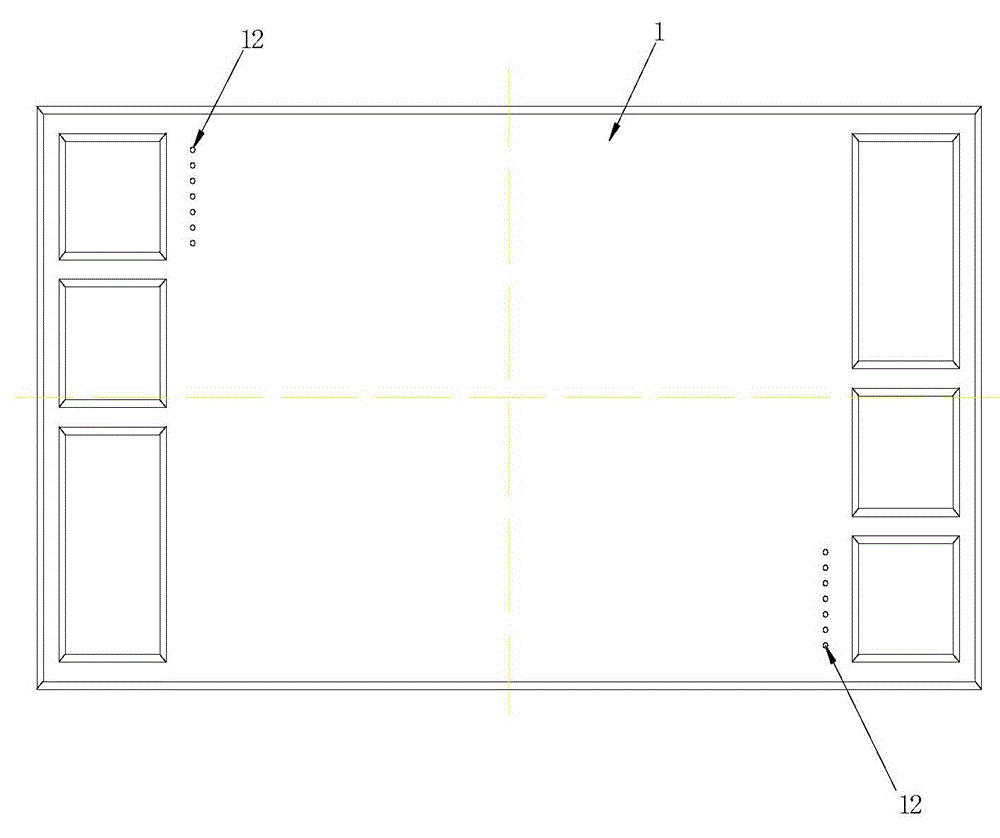

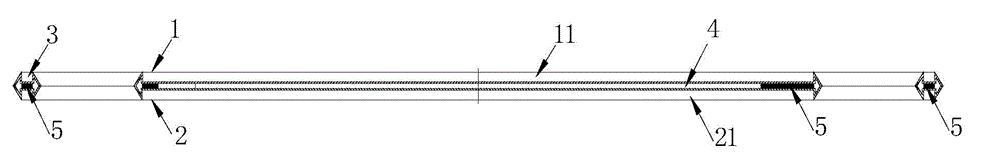

[0024] A metal bipolar plate for a 60kw proton exchange membrane fuel cell, with a length and width of 100×400mm, such as Figure 1~4 As shown, the metal bipolar plate is stamped from two 0.2mm stainless steel metal plates with the same thickness to form a hydrogen pole plate 1 and an oxygen pole plate 2. Both the hydrogen pole plate 1 and the oxygen pole plate 2 are provided with common hydrogen channel openings, and the common Oxygen channel openings, common cooling fluid openings, and sealing grooves are provided along both sides and the sides of the common fluid openings. The sealing grooves are 4mm wide and 0.4mm deep. A 0.4mm thick soft graphite plate in the shape of a straight groove is extruded to form a hydrogen pole plate, and a soft graphite plate with a thickness of 0.4mm that guides the air flow is placed in the cavity formed by stamping on the oxygen pole 2. Oxygen pole plate is formed, and the depth of the cavity of the hydrogen-conducting airflow and the cavity...

Embodiment 2

[0027] The bracket is made of rubber or plastic material, and is pressed and bonded together with the hydrogen pole plate and the oxygen pole plate.

[0028] The three cavities are respectively placed with a porous carbon diffusion layer conductive material without the overall shape of the flow tank, and the thickness is the same as that of the soft graphite sheet. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com