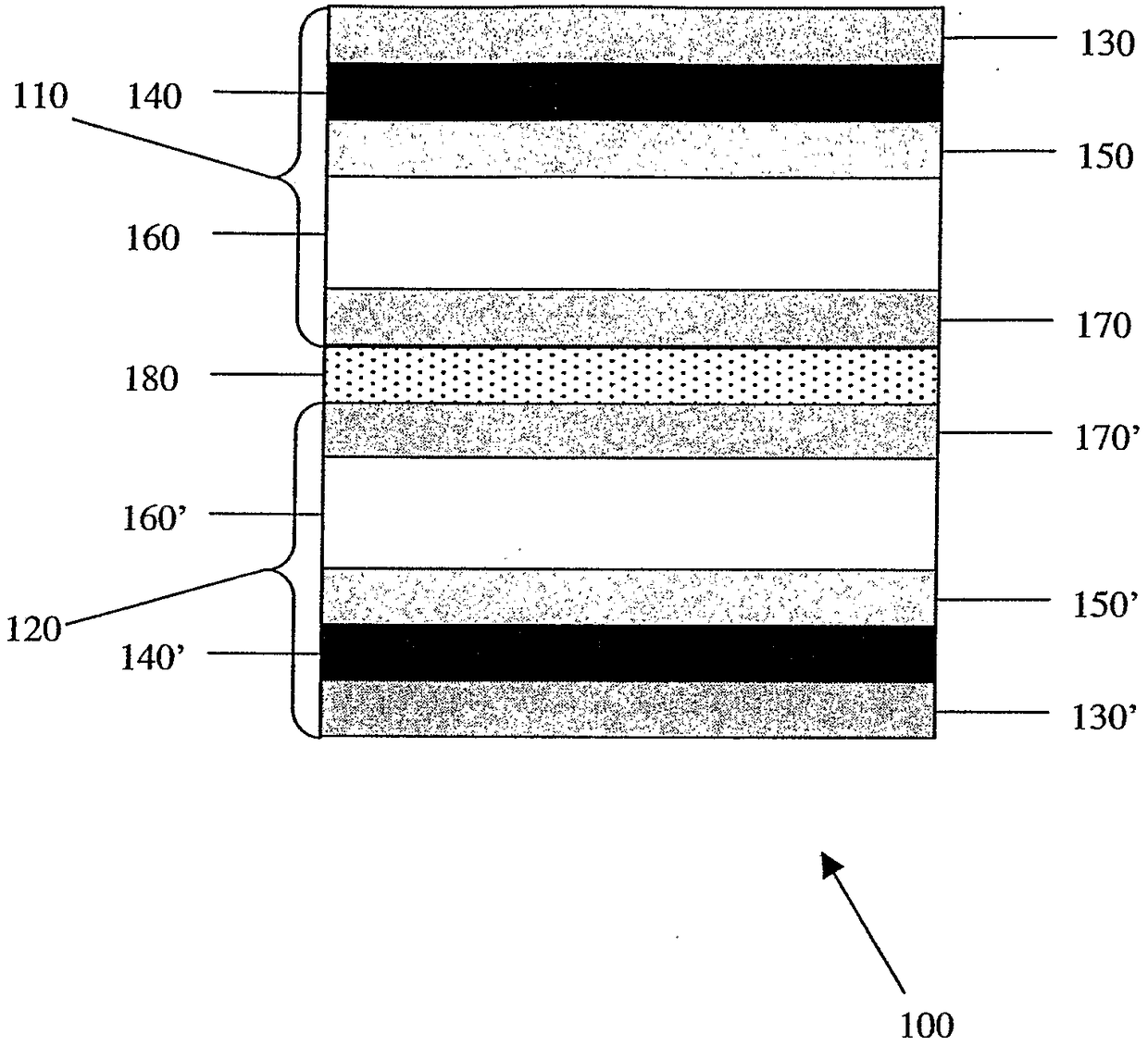

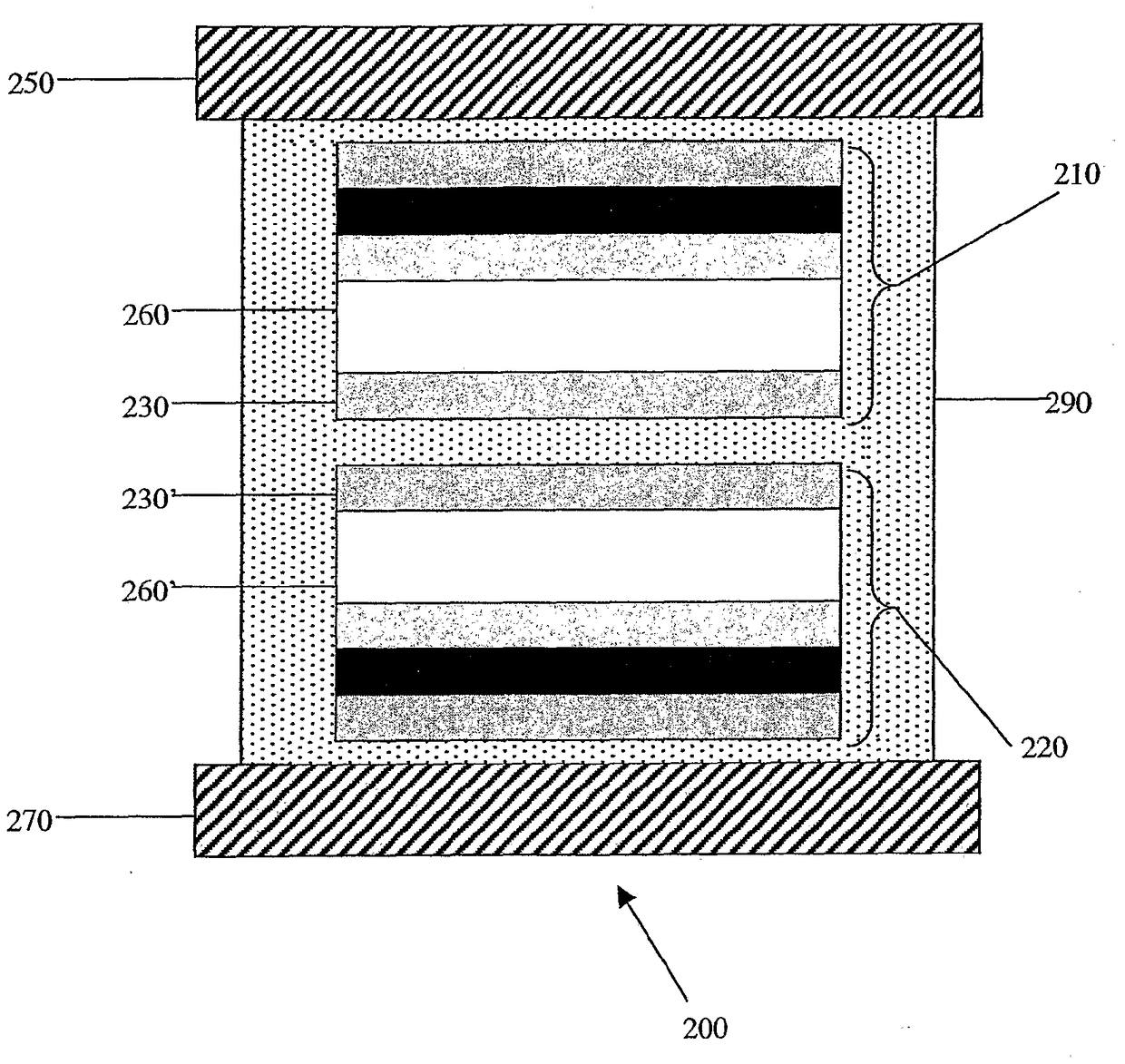

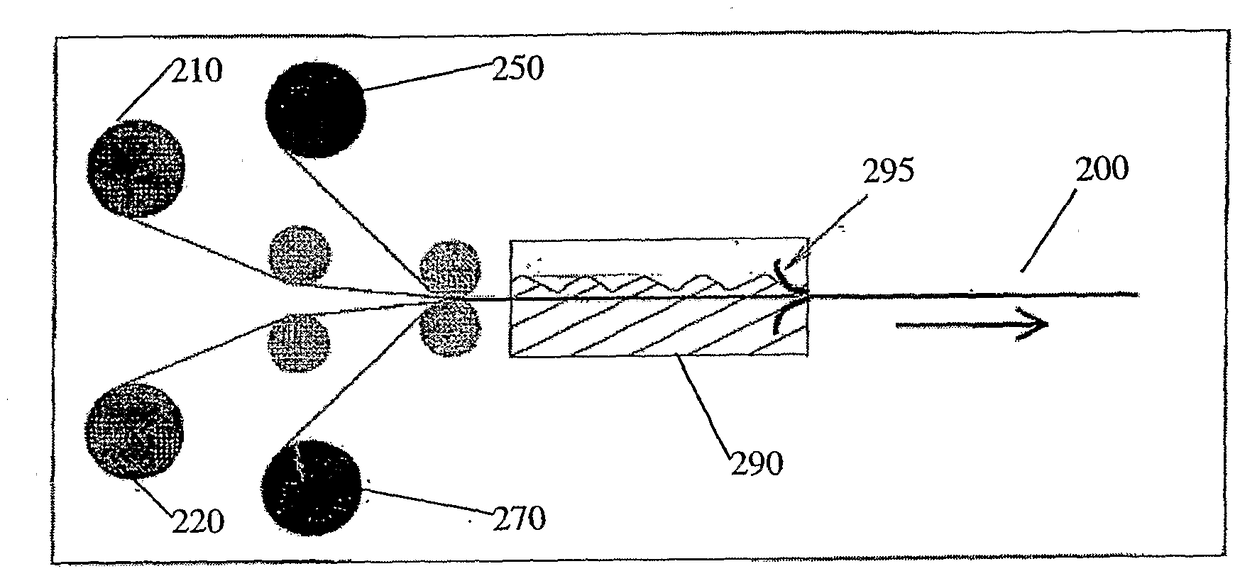

Structure of High Temperature Superconductor Wire

一种超导体、超导体层的技术,应用在超导体元素的用法、超导体装置的制造/处理、超导体零部件等方向,能够解决降低HTS层电性能、缓慢、导线污染等问题,达到高电流承载能力、改进电流分配、易于使用的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0125] Example 1: Preparation of multilayer conductors with double-coated superconductor layers of different compositions.

[0126] By adding about 0.85 g of Y(CF 3 CO 2 ) 3 , about 1.45 g of Ba(CF 3 CO 2 ) 2 and about 1.35 grams of Cu(C 2 h 5 CO 2 ) 2 Dissolve in approximately 4.85 mL of methanol (CH 3 OH) and about 0.15 mL of propionic acid (C 2 h 6 CO 2 ) to prepare the base YBCO precursor solution with a stoichiometry of 1:2:3.23 Y:Ba:Cu. The final volume of the solution was adjusted to about 5 mL with methanol.

[0127] By adding 1.70 g of Dy(CH 3 CO 2 ) 3 and approximately 1.90 mL of methanol (CH 3OH) was dissolved in about 20 mL of the base solution to prepare a base YBCO precursor solution with 50% dysprosium additive with a stoichiometry of Y:Dy:Ba:Cu of 1:0.5:2:3.23. The final volume of the solution was adjusted to about 25 mL with the base solution.

[0128] By putting 1.24 g of Cu(C 2 h 5 CO 2 ) 2 The powder was dissolved in 4.85 mL of methan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com