A device and method for measuring surfactant concentration distribution of CO2 emulsion during percolation

A technology of surfactant and determination method, applied in the direction of measuring device, analytical material, instrument, etc., can solve the problem of no measurement and no given surfactant concentration distribution, etc., and achieve the effect of high accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

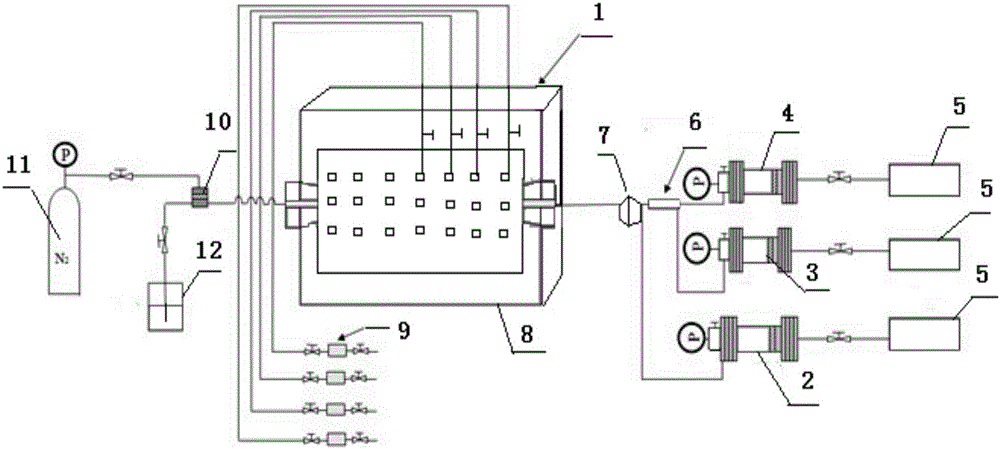

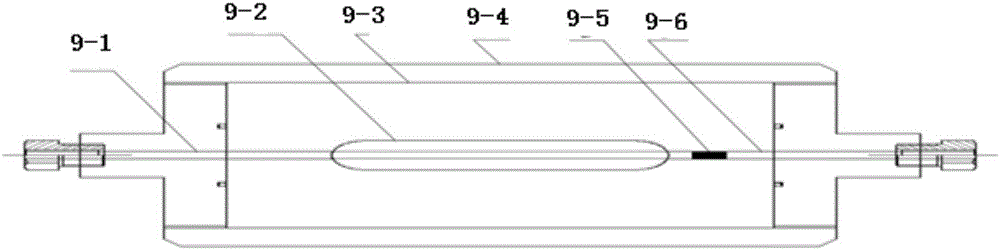

[0029] Such as figure 1 , 2 As shown, a measurement of CO 2 The device for the concentration distribution of the surfactant during the seepage of the emulsion includes a square sand-filled core model 1 filled with quartz sand; the sand core model includes a square metal shell 9-4, and a square inner shell 9-4 is arranged inside the shell 9-4. cavity, the inner cavity is filled with quartz sand with a particle size between 120 and 140 mesh, the inlet and outlet ends of the shell 9-4 are respectively provided with threaded joints, and there are 21 sampling ports on the top surface of the sand-filled core model 1 8. The sand-filled core model 1 is surrounded by a heating insulation cover, which is convenient for heating and insulation.

[0030] The inlet end of the sand-packed core model 1 is connected with a phase-parallel emulsion generator and a crude oil piston 9-5 type intermediate container 2 through a six-way valve 7, and the inlet end of the emulsion generator is conne...

Embodiment 2

[0034] Adopt embodiment 1 to measure CO 2 The assay method that the device that the surfactant concentration distribution of emulsion carries out during percolation process comprises the following steps:

[0035]Step 1: Heat the core temperature of the sand-filled core model 1 to 30°C to 90°C, and maintain the temperature for 12 hours, and then apply confining pressure to the core through the gas source bottle 11; set the back pressure to 10MPa, and the pressure is The outlet pressure of the sand pack model determines the reservoir conditions where the sand pack model is located.

[0036] Step 2, vacuumize the core of sand-filled core model 1 and saturate it with water, then pump crude oil into the core until the core is displaced by crude oil to the state of irreducible water;

[0037] Step 3, using advection pump 5 to separate the CO 2 CO in intermediate container 4 of gas piston 9-5 type 2 Gas and surfactant piston 9-5 The surfactant solution in the intermediate containe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com