Efficient mute range hood

A range hood and mute technology, which is applied in the field of high-efficiency and quiet range hoods, can solve problems such as limited grease separation effect, suction power loss, and high noise of the range hood, and achieve the effects of avoiding smoking dead ends, reducing losses, and efficiently exhausting smoke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

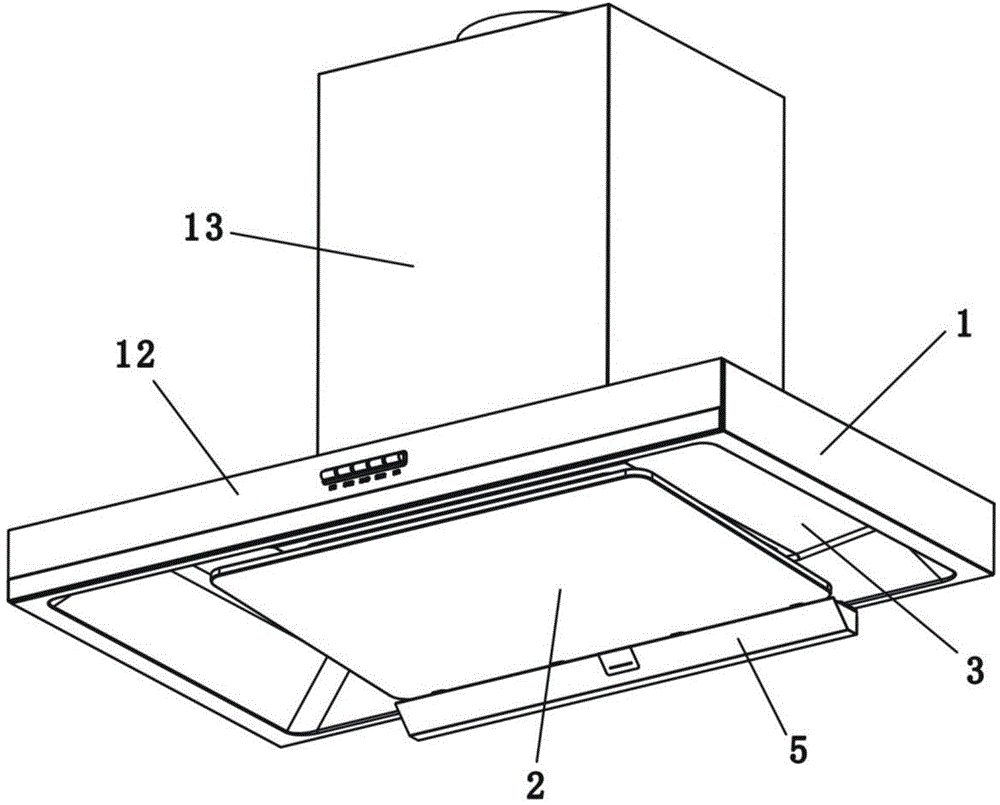

[0028] Such as Figure 1 to Figure 6 The range hood shown has a housing 1 on which an air inlet 11 is provided. The range hood is equipped with a separating baffle 2 that shields the air inlet 11, and the separating baffle 2 includes an outer layer The plane separating plate 21 and the inner baffle 22, the middle of the baffle 22 is raised, and the air inlet channel 3 gradually decreases from the edge of the baffle 22 to the center. The range hood of the present invention is provided with a separating baffle 2, which realizes the separation of grease on the outer layer and efficient diversion in the inner layer. The middle of the baffle 22 is raised, so that the air inlet channel 3 is separated from the baffle 2 There is a gradually decreasing flow path towards the center of the air inlet, which speeds up the flow of wind speed, and has higher smoking efficiency. Moreover, the middle part of the baffle 22 is raised to avoid the collection of air intake on the outer periphery of ...

Embodiment 2

[0034] The difference between this embodiment and the first embodiment is as follows: Figure 7 to Figure 9 , The arc surface is from the edge to the center of the separation deflector, and the radius of curvature gradually decreases. That is, the arc gradually increases, and when the oil smoke moves along the deflector 22, it is always subjected to a thrust acceleration of the arc surface 221 pointing to the center of the circle, and the oil smoke can be further condensed in the air inlet channel 3 to collect oil. In this embodiment, the range hood is a side suction hood, the housing 1 includes a body 17 and an upper cover, a fan is installed in the housing 1, and a concave set is provided on the front of the body 17 An air inlet 11 is opened on the smoke collecting hood 14, the separating baffle 2 is installed in front of the air inlet 11, and an oil receiving box 5 is arranged under the smoke collecting hood 14. The separation deflector 2 of the side suction hood can adopt ...

Embodiment 3

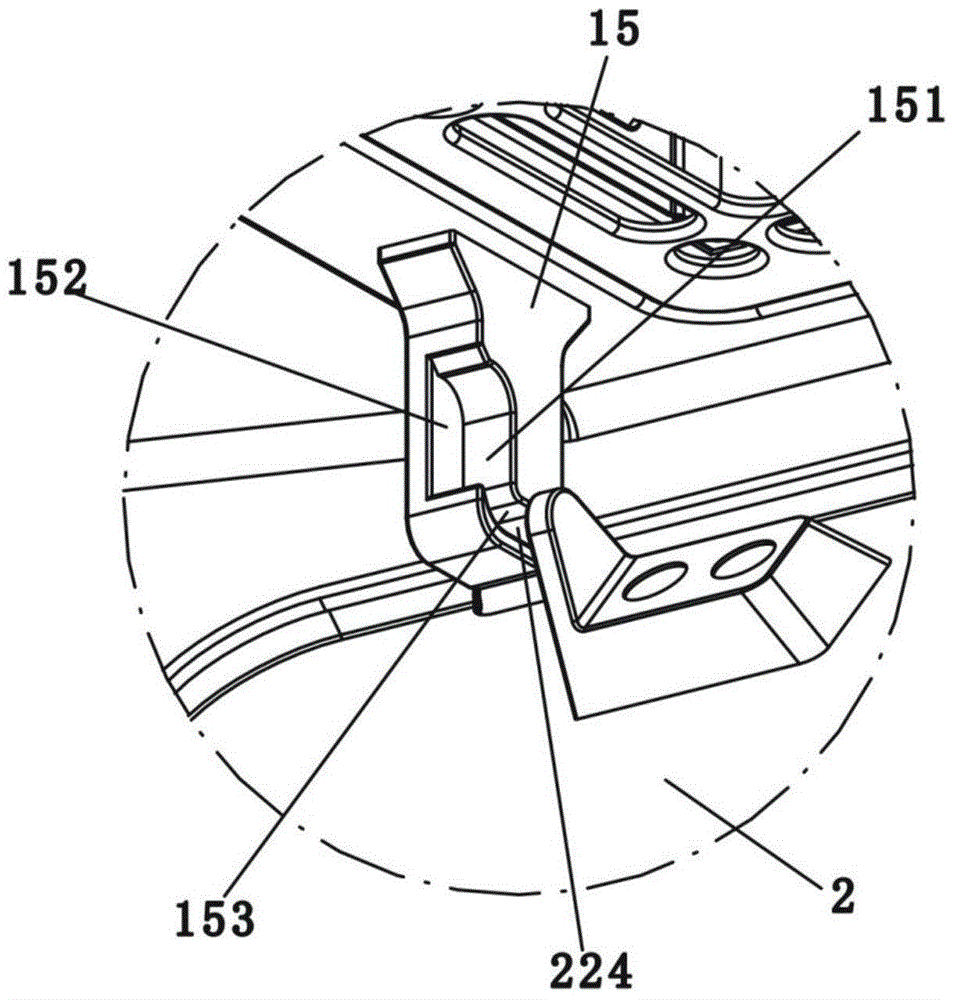

[0037] The difference between this embodiment and the first embodiment is as follows: Picture 10 The baffle 22 has a baffle curved surface 224, which is a smooth curved surface with a raised middle part. The curved surface is symmetrical with the center of the separated baffle as the central axis. The curved surface on the side of the central axis has an inflection point. The portion of the deflector curved surface 224 near the edge is on the concave curved surface, the portion near the center of the bulge is on the convex curved surface, and the concave curved surface and the convex The intersection of the arcs is the inflection point of the two arcs. Setting the inflection point can make the deflector 22 a smooth continuous curved surface, which facilitates the stamping and forming of the deflector 22. In this embodiment, the two front and rear deflector slopes 223 are not used, and the deflector 22 is a whole smooth curved surface to ensure The protruding part is located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com