A supersonic combustion chamber flame stabilization device

A flame stabilization and combustion chamber technology, applied in combustion methods, combustion equipment, fuel supply, etc., can solve problems affecting flame stability, total pressure loss, etc., and achieve the effect of ensuring flame stability, small pressure loss, and enhanced mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

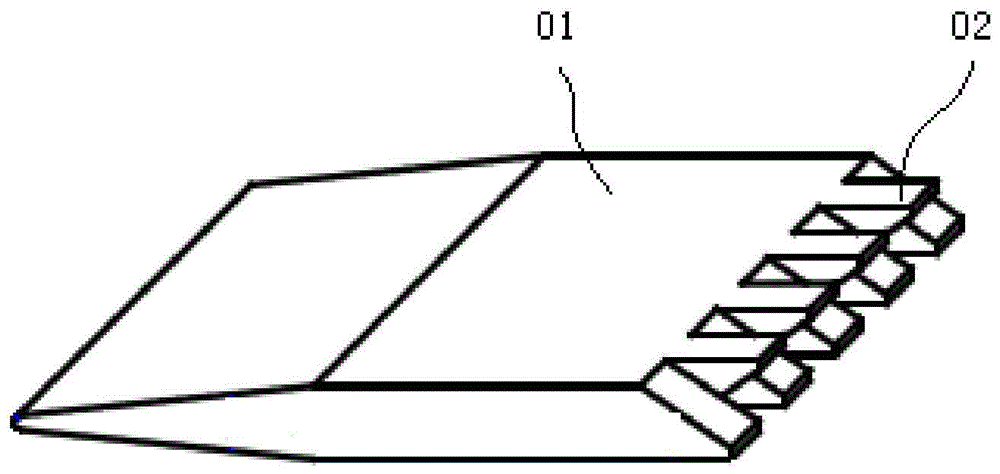

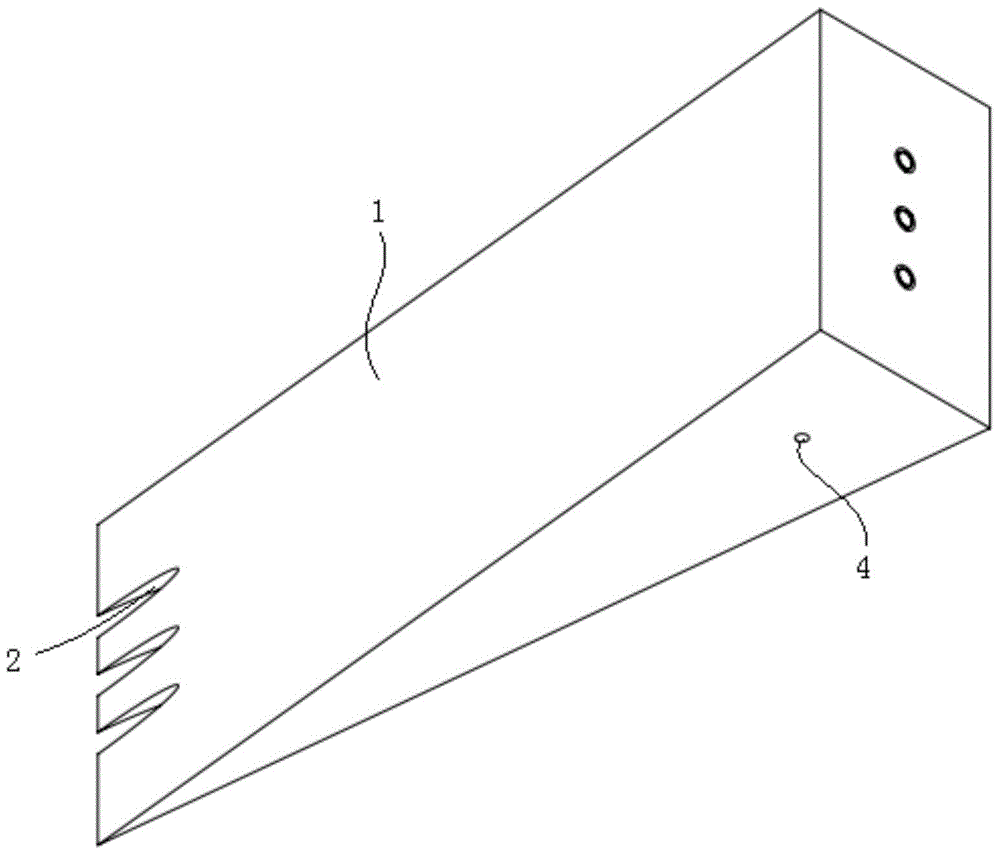

[0031] as attached figure 2 to the attached Figure 7 shown, with figure 2 to the attached Figure 7 A specific embodiment of a supersonic combustion chamber flame stabilization device is provided.

[0032] The flame stabilizing device of the supersonic combustion chamber includes: a support plate 1 installed and fixed inside the supersonic combustion chamber.

[0033] The oxidant through-holes 2 are arranged inside the support plate 1 for the transmission of the oxidant. The number of the oxidant through-holes 2 can be specifically selected according to the needs. In this embodiment, three parallel oxidant through-holes 2 are provided. One end of the oxidant through hole 2 is an air inlet for the input of oxidant; It is arranged on the rear edge of the support plate 1.

[0034] The spiral guide groove 3 is arranged on the inner wall of the oxidant through hole 2, and is used to drive the oxidant to spirally rotate in the oxidant through hole 2. Specifically, when the s...

Embodiment 2

[0043] The present invention also provides a specific embodiment when the supersonic combustion chamber flame stabilization device is in use, wherein, Figure 8 It is a schematic diagram of the structure of the device of the present invention installed in the flow channel.

[0044] as attached Figure 8As shown, the height of the flow channel provided by this embodiment is 50 mm, the upper and lower parts of the front section of the flow channel are parallel, and the upper surface of the flow channel at a distance of 23 mm from the front edge of the support plate expands outward by 3°, and the support plate 1 is set at the middle position in the height direction of the flow channel. The support plate 1 used in this embodiment is a wedge-shaped support plate, the total length of which is 32 mm, the distance from the front edge of the wedge-shaped support plate to the fuel conduit 4 is 23 mm, and the angle between the upper surface and the lower surface of the wedge-shaped suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com