Movable sealing device and use method thereof

A technology of moving seals and sealing lips, which is applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of frequent relative movement and inflexible sealing, and achieve the effect of easy disassembly and guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

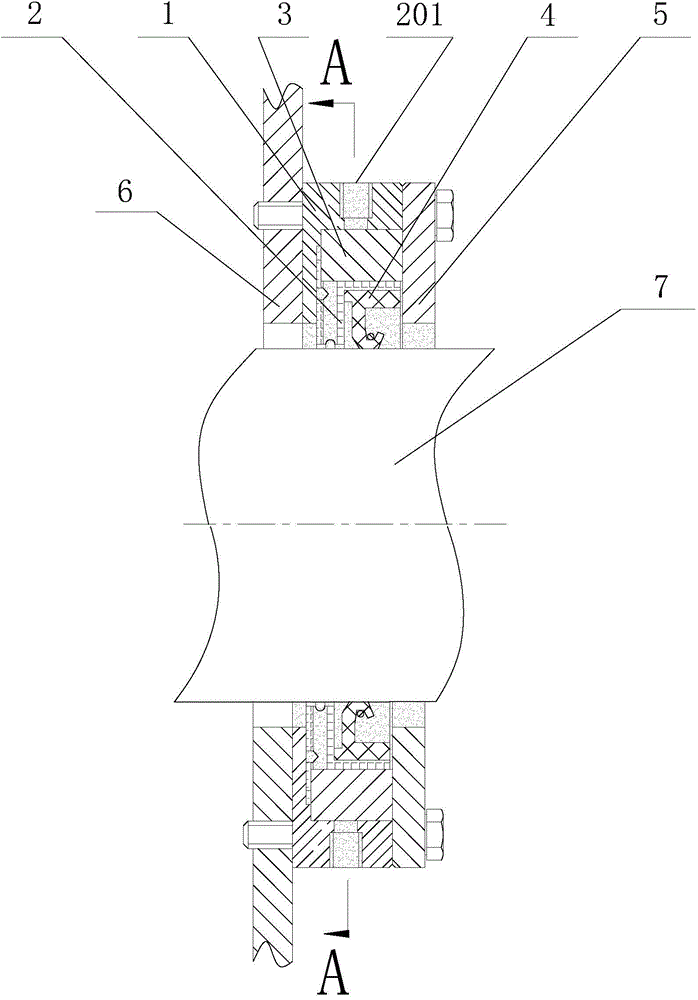

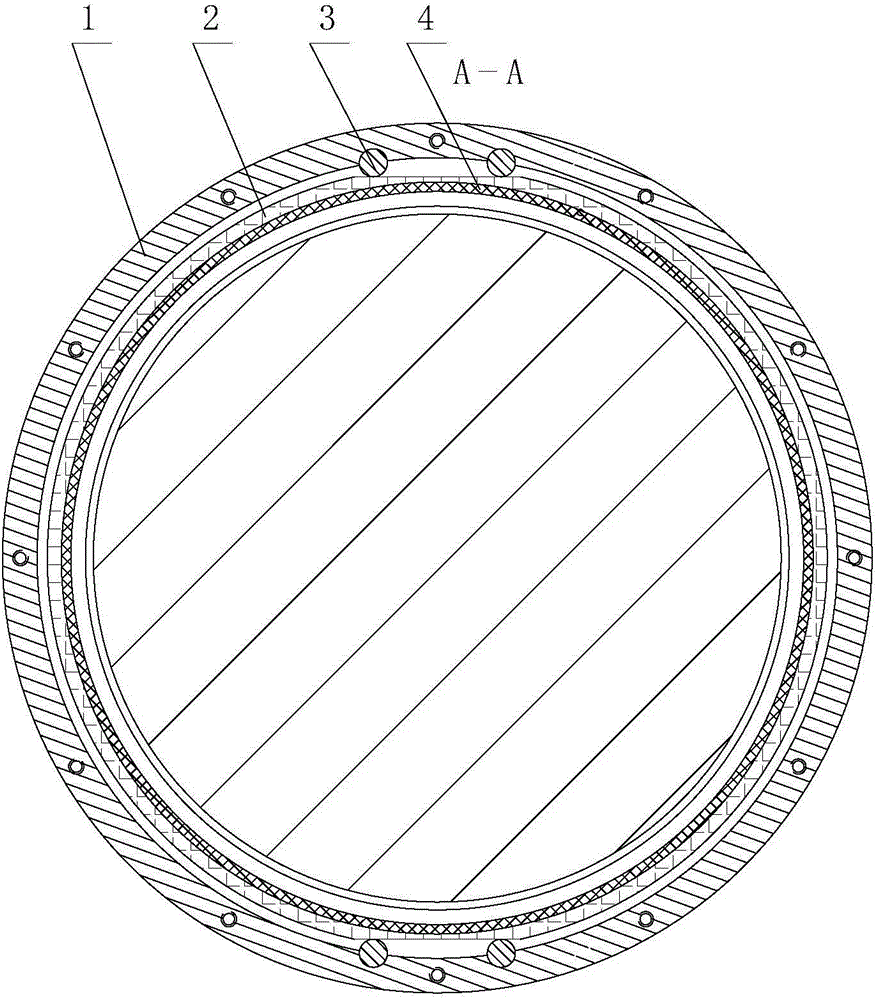

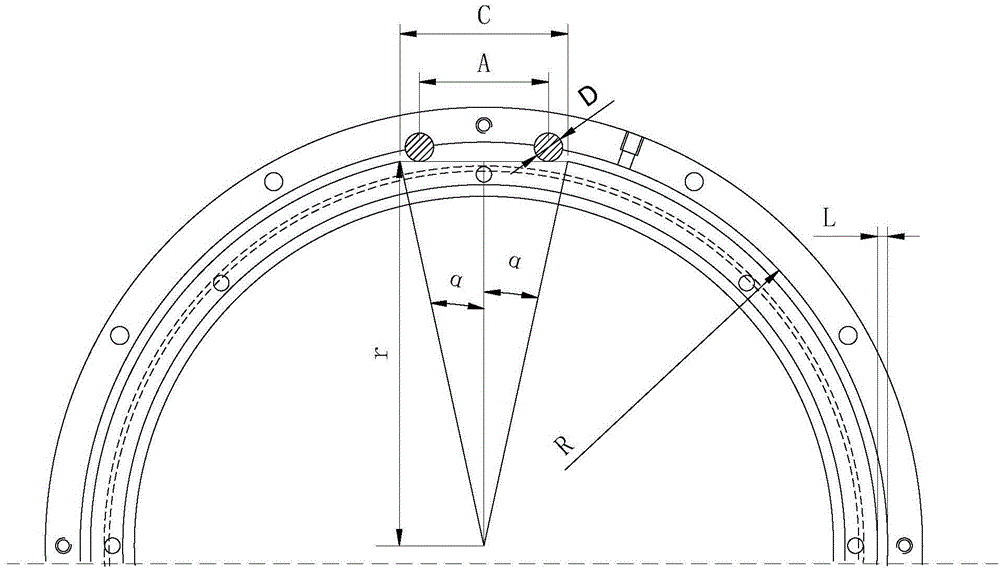

[0032] Such as figure 1 , figure 2 with image 3 As shown, a movable sealing device includes an outer ring body 1, an inner ring body 2, a rubber sealing ring 4, a gland 5 and a limiting rod 3. The outer ring body 1 and the inner ring body 2 are both circular, Both the outer ring body 1 and the inner ring body 2 have a "7" shape in cross section, which is divided into vertical and horizontal planes; the outer diameter of the outer ring body 1 is 0.2m, the thickness is 35mm, and the inner diameter 2R of the outer ring body 1 is 183mm , The difference 2L between the inner diameter of the outer ring body 1 and the outer diameter of the inner ring body 2 is 5mm, an annular groove is provided inside the horizontal plane of the outer ring body 1, and the thickness of the inner ring body 2 is smaller than the annular groove inside the outer ring body 1. The inner ring body 2 is set in the annular groove; the rubber sealing ring 4 is an annular fold-like structure with a "J"-shaped cr...

Embodiment 2

[0035] Such as figure 1 , figure 2 with image 3 As shown, a movable sealing device includes an outer ring body 1, an inner ring body 2, a rubber sealing ring 4, a gland 5 and a limiting rod 3. The outer ring body 1 and the inner ring body 2 are both circular, The sections of the outer ring body 1 and the inner ring body 2 are both in the shape of "7", divided into vertical and horizontal planes; the outer diameter of the outer ring body 1 is 1.0m, the thickness is 45mm, and the inner diameter 2R of the outer ring body 1 is 914mm , The difference 2L between the inner diameter of the outer ring body 1 and the outer diameter of the inner ring body 2 is 24mm, an annular groove is provided inside the horizontal plane of the outer ring body 1, and the thickness of the inner ring body 2 is smaller than the annular groove inside the outer ring body 1. The inner ring body 2 is set in the annular groove; the rubber sealing ring 4 is an annular fold-like structure with a "J"-shaped cros...

Embodiment 3

[0038] Such as figure 1 , figure 2 with image 3 As shown, a movable sealing device includes an outer ring body 1, an inner ring body 2, a rubber sealing ring 4, a gland 5 and a limiting rod 3. The outer ring body 1 and the inner ring body 2 are both circular, Both the outer ring body 1 and the inner ring body 2 have a "7" shape in cross section, divided into vertical and horizontal planes; the outer diameter of the outer ring body 1 is 2.0m, the thickness is 60mm, and the inner diameter 2R of the outer ring body 1 is 1828mm , The difference 2L between the inner diameter of the outer ring body 1 and the outer diameter of the inner ring body 2 is 48mm, the inner side of the outer ring body 1 is provided with an annular groove, and the thickness of the inner ring body 2 is smaller than that of the inner ring body 1 The inner ring body 2 is set in the annular groove; the rubber sealing ring 4 is an annular fold-like structure with a "J"-shaped cross-section, and the "J"-shaped cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com