Bionic shale inhibitor and preparation method thereof and drilling fluid and application thereof

A shale inhibitor and drilling fluid technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of unsatisfactory performance of shale inhibitors, environmental hazards of shale inhibitors, etc. Wall instability, good environmental performance, high positive charge density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

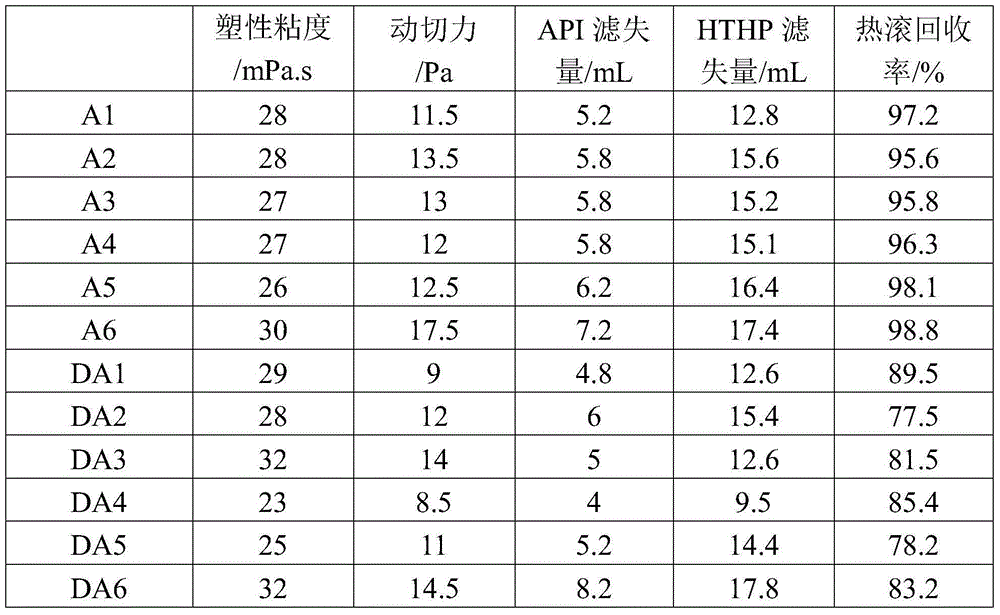

Examples

preparation example Construction

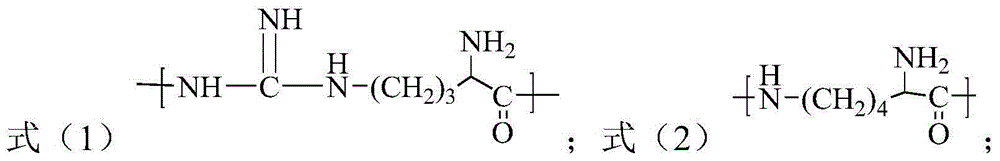

[0023] The present invention also provides a method for preparing a bionic shale inhibitor, wherein the method comprises: in the presence of an inorganic acid catalyst, performing a condensation reaction of arginine and lysine; the arginine and lysine The molar ratio of the amount used is 0.2-6:1; the condensation reaction conditions make the weight average molecular weight of the obtained polymer 800-4000g / mol.

[0024] According to the present invention, the above-mentioned arginine can be L-form, D-form or a mixture of the two, and the above-mentioned lysine can be L-form, D-form or a mixture of the two. Preferably L-arginine and L-lysine are used.

[0025] According to the present invention, the amount of the arginine and lysine is not particularly limited, as long as the weight average molecular weight of the product of the condensation reaction is 800-4000 g / mol, preferably, the arginine The molar ratio of amino acid and lysine is 0.3-0.5:1, preferably 1-5:1, preferably...

Embodiment 1

[0052] This example is used to illustrate the biomimetic shale inhibitor of the present invention and its preparation method.

[0053] At 195°C, stir and mix 0.5mol (87.1g) of L-arginine and 0.2mol (29.2g) of L-lysine, and add 1.75mol (171.5g) of phosphoric acid (85% by weight of phosphoric acid aqueous solution), and reacted at 195°C for 16h. After the reaction was completed, when the temperature dropped to about 120° C., 200 g of water was added thereto, and the stirring was continued for 20 minutes until the product was completely dissolved in water. Then, the aqueous solution of the reaction product is taken out and dried at about 120° C. to obtain a solid, which is dissolved in dimethyl sulfoxide, and the insoluble matter is separated from the solution by suction filtration. Then the solution was evaporated to dryness by rotary evaporation to obtain 91.8 g of the biomimetic shale inhibitor of the present invention. Measure its weight-average molecular weight M by gel pe...

Embodiment 2

[0055] This example is used to illustrate the biomimetic shale inhibitor of the present invention and its preparation method.

[0056] At 200°C, stir and mix 0.8mol (139.4g) of L-arginine and 0.2mol (29.2g) of L-lysine, and add 0.35mol (34.3g) of phosphoric acid (85% by weight of phosphoric acid aqueous solution), and reacted at 200°C for 8.5h. After the reaction was completed, when the temperature dropped to about 120° C., 200 g of water was added thereto, and the stirring was continued for 20 minutes until the product was completely dissolved in water. Then, the aqueous solution of the reaction product is taken out and dried at about 120° C. to obtain a solid, which is dissolved in dimethyl sulfoxide, and the insoluble matter is separated from the solution by suction filtration. Then the solution was evaporated to dryness by rotary evaporation to obtain 145.8 g of the biomimetic shale inhibitor of the present invention. Measure its weight-average molecular weight M by gel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| filtration | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com