Combined packing case capable of being recovered and quickly dismantled

A packaging box and quick-dismantling technology, which is applied in the field of recyclable quick-dismantling combined packaging boxes, can solve the problems of unreusable box boards, inconvenient installation and disassembly, poor safety and reliability, etc., so as to facilitate storage and logistics recycling, and have a simple structure , the stable effect of the box

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] In the prior art, the packaging box is usually used for one-time use due to a large number of nails for fixing, and it is not easy to disassemble. The present invention aims at the characteristics of the combined packaging box. In order to facilitate the recovery and quick disassembly of the box body, the following improvements are made to the packaging box :

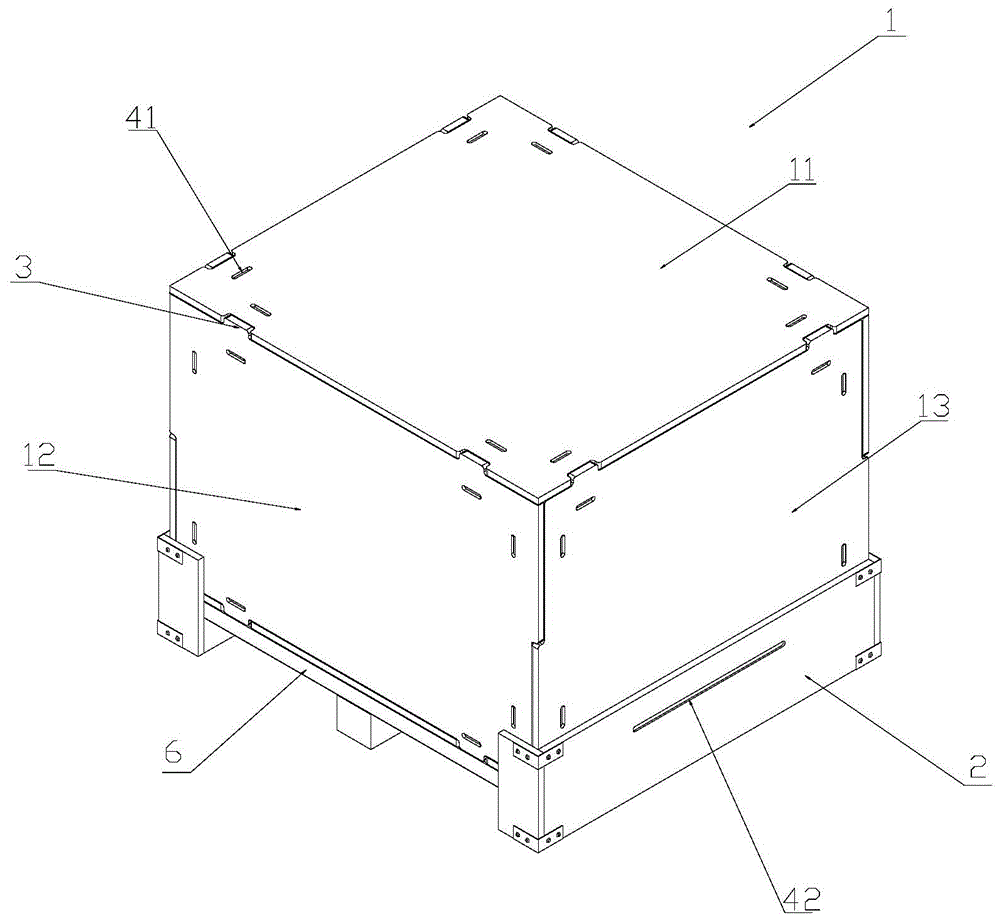

[0080] refer to figure 1 As shown, the box body is composed of multiple panels, including four side panels (front and rear side panels 13, left and right side panels 12), a top panel 11, and a bottom tray 6. The bottom tray includes two side beams arranged in parallel 63, screw the bottom plate 61 on the side beam ( Figure 4 Shown), the length and width of the top plate 11 and the bottom tray 6 are equal. The splicing edges between the top plate 11 and the side plates and between adjacent side plates are all engaged and connected by at least one male and female groove structure 3, and the male and female groov...

Embodiment 2

[0088] Packing boxes are widely used in all walks of life, and the second embodiment is aimed at the transportation of pipes and coils. Pipes are brittle and easily deformed. During transportation, pipes stacked together are prone to collision and damage. In order to solve the above problems, the second embodiment makes the following box improvements on the basis of the first embodiment: Figure 6 As shown, two storage boards 8 are added in the box, the storage boards 8 are arranged on the inside of the front side board and the rear side board, and the two sides of the storage board 8 are provided with outwardly protruding inserting boards 84. , the bottom of the storage board is plugged on the bottom board 61 through the plug-in structure, and the plug-in board 84 is inserted into the preset bayonet slots on the left side board and the right side board of the cabinet. For ease of processing, the top card grooves on both sides of the left side plate and the right side plate a...

Embodiment 3

[0093] Embodiment 3 is aimed at the packaging boxes of two-wheeled motor vehicles such as motorcycles and Qingqi. Therefore, when designing, the following factors need to be considered: how to fix the wheels; The volume of the box is large, how to optimize the design to reduce the logistics cost.

[0094] Based on the above characteristics, on the basis of Embodiment 1, Embodiment 3 makes the following box improvements: Figure 10As shown, the bottom plate 61 may not be provided on the side beams 63 of the bottom tray 6, and the first cross beam 64, the middle cross beam 62 and the second cross beam 65 are arranged below the two side beams 63; the first cross beam 64, the second cross beam 65 and two support A front wheel positioning plate and a rear wheel positioning plate are respectively arranged between the beams 22. The front wheel positioning plate includes two oblique support bars 66 arranged at parallel intervals, and the rear wheel alignment plate includes two straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com