A steel ball counting machine

A technology of counting machine and steel ball, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of reducing efficiency, affecting the number of packaging, high cost, etc., to prevent surface quality defects, ensure surface quality, and easy to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

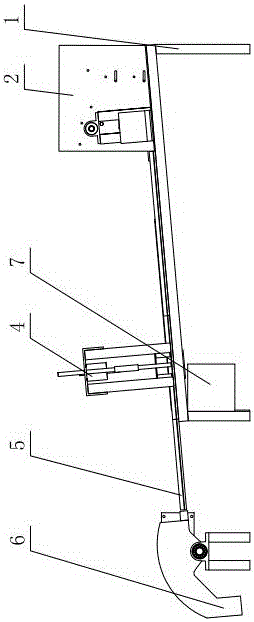

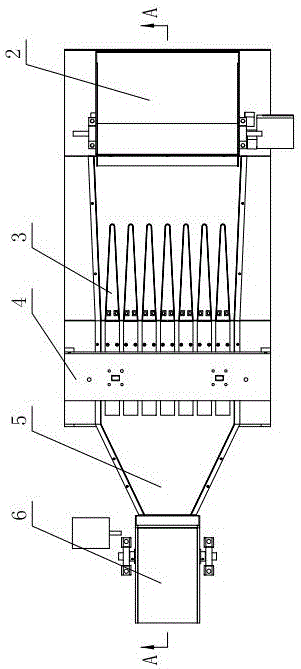

[0032] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the steel ball counting machine of the present embodiment includes a frame 1, a feeding device 2 is installed on the right end of the frame 1, and a track substrate 5 is installed in connection with the feeding device 2, and the track substrate 5 is located on the platform of the frame 1. The head of the track base plate 5 is trapezoidal and suspended on the left end of the frame 1. The counting track 3 is installed on the track base plate 5. The ball control valve device 4 is installed on the top of the counting track 3, and the control valve device 4 is installed on the bottom of the frame 1. The head of the cabinet 7 and the track base plate 5 is also connected with an auxiliary packaging device 6 .

[0034] The feeding device 2 feeds intermittently, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com