5052 aluminum alloy end stock substrate and production method thereof

A production method and technology of aluminum alloy, applied in the field of aluminum alloy manufacturing, can solve the problems of long time consumption of cold rolling, unwinding and unwinding, fire accidents, increased energy consumption costs, etc., so as to reduce the probability of surface quality defects and prevent fire Accidents, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

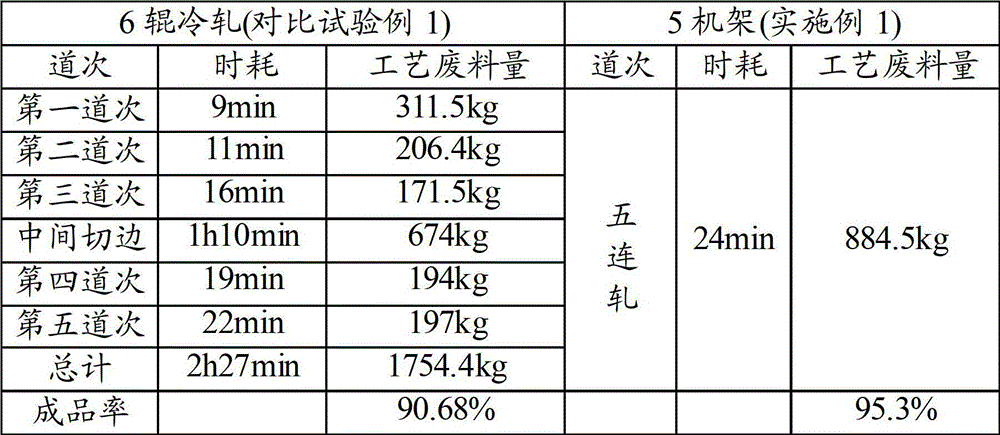

Embodiment 1

[0023] The alloy state of the 5052 aluminum alloy can lid material base material described in this embodiment: 5052 / H48; the thickness of the finished product: 0.22mm; its production process includes: production process: melting and casting → sawing → milling → heating → hot continuous rolling → cold Continuous rolling→tension bending straightening→coating→finished product shearing, the specific process parameters are as follows:

[0024] (1) Casting

[0025] The mass percentages of the chemical composition of molten aluminum after casting are: Si0.048%, Fe0.282%, Cu0.003%, Mn0.012%, Mg2.41%, Cr0.22%, Zn0.018%, Ti0.012 %, V0.017%, Ni0.003%, Pb0.001%, Cd0.0001%, Na0.0001%, and the rest is Al; the melting temperature is 742°C, the refining temperature is 730°C, and the casting temperature is 685°C.

[0026] (2) Heating: the heating temperature of the ingot is 500° C., and the holding time is 3 hours.

[0027] (3) Hot rolling: use 1+5 hot rolling mills, first roll 25 passes in ...

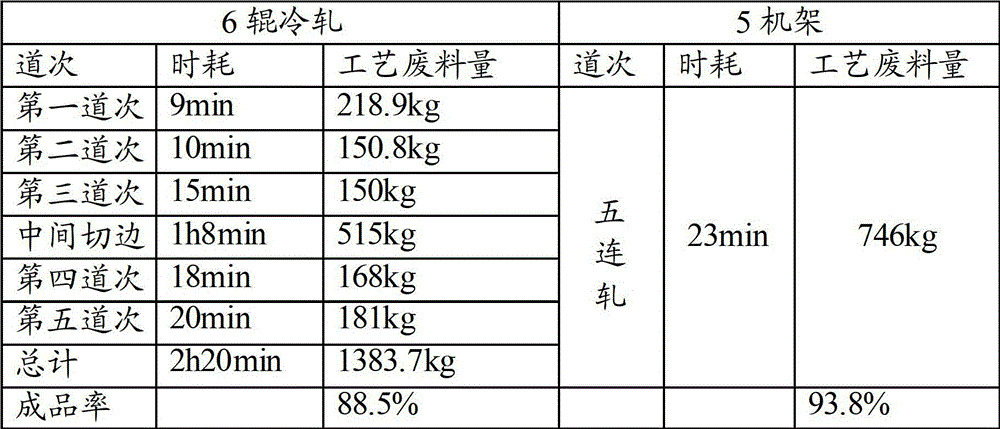

Embodiment 2

[0056] The alloy state of the 5052 aluminum alloy can lid material base material described in this embodiment: 5052 / H48; the thickness of the finished product: 0.26mm; its production process includes: production process: melting and casting → sawing → milling → heating → hot continuous rolling → cold Rolling→tension bending straightening→coating→finished product shearing, the specific process parameters are as follows:

[0057] (1) Casting

[0058] The mass percentage of the chemical composition of molten aluminum after casting is: Si0.057%, Fe0.283%, Cu0.0053%, Mn0.017%, Mg2.46%, Cr0.22%, Zn0.017%, Ti0.013 %, V0.017%, Ni0.003%, Pb0.0006%, Cd0.0001%, Na0.0001%, and the rest is Al; the melting temperature is 739°C, the refining temperature is 728°C, and the casting temperature is 682°C.

[0059] (2) heating: with embodiment 1.

[0060] (3) Hot rolling: use 1+5 hot rolling mills, firstly roll 25 passes in the roughing mill, and then roll in the 5-stand continuous rolling mill,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com