Battery package heat-seal device

A technology for batteries and heating sheets, applied in the directions of packaging, transportation packaging, transportation and packaging, can solve the problems of unreasonable structural design of battery packaging devices, reducing the appearance of battery packaging boxes, and easily scalding operators, and saving labor. Cost, beautiful appearance, convenient effect of heat sealing components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

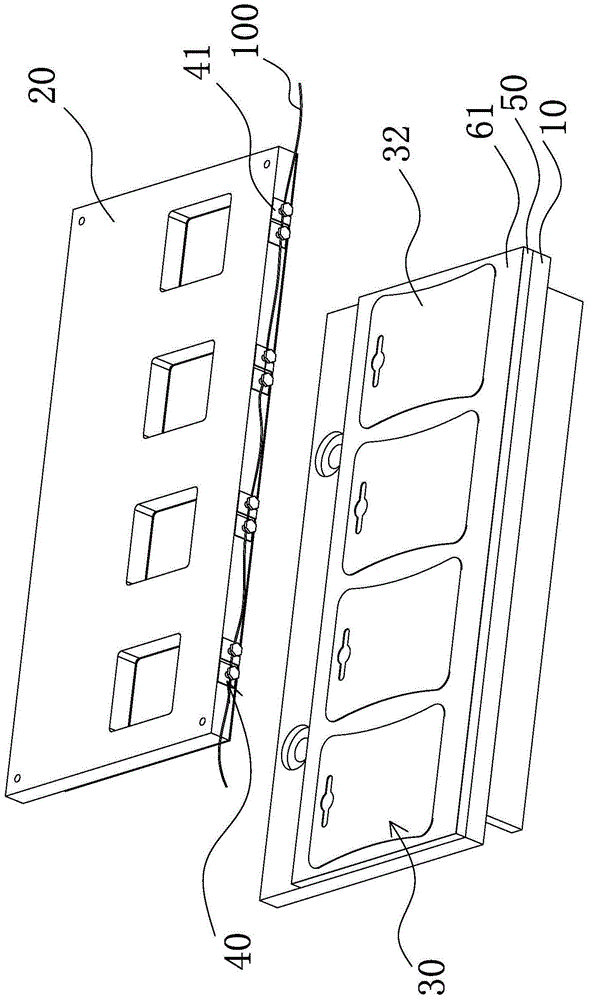

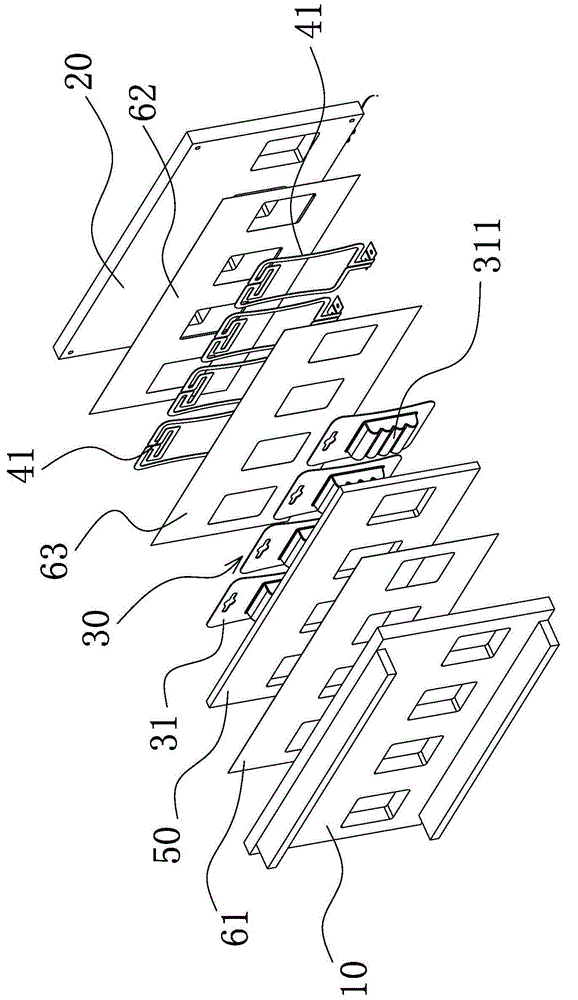

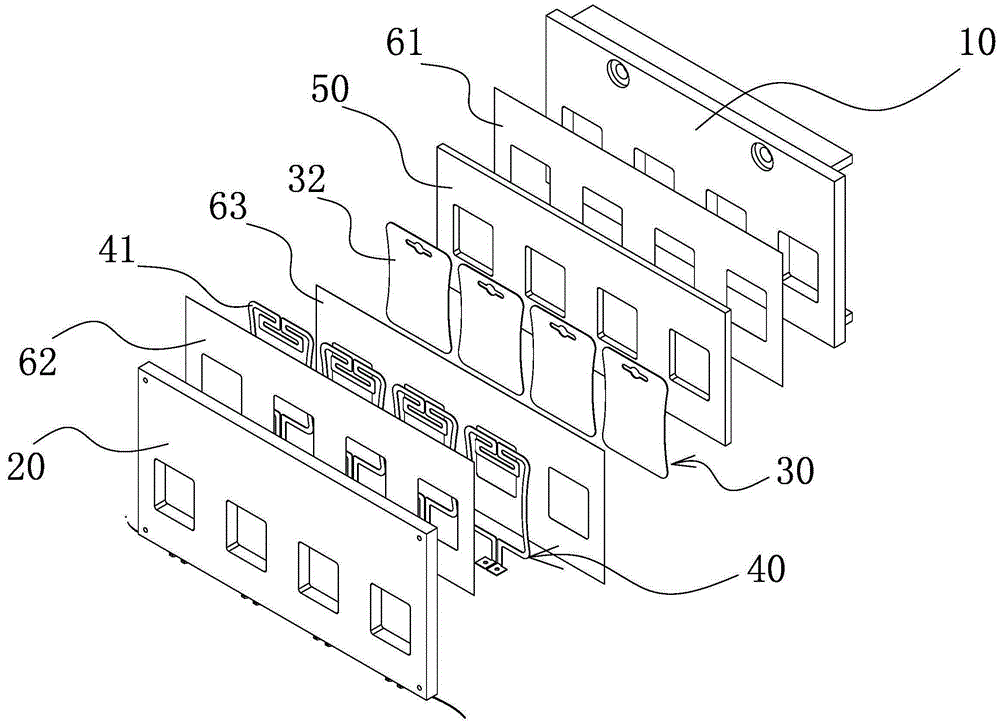

[0027] The present invention protects a battery packaging heat-sealing device that heat-seals a battery packaging card 30 into a battery packaging box, and is used to wrap a plurality of batteries into shrinkable batteries.

[0028] The structural design of the existing battery packaging device is unreasonable. It includes a lower mold and the battery is placed on the lower mold. Generally, the packaging card 30 is heat-sealed and formed into a battery packaging box by using a heat-sealing method. The packaging box has obvious heat-sealing traces and the heat-sealing traces are located on the same surface as the shrunk battery (that is, the front of the battery packaging box), which reduces the aesthetics of the battery packaging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com