Tumbler ship model

A tumbler and ship-shaped technology, which is applied to the safety of ships, ships, transportation and packaging, etc., can solve the problems of poor stability and safety, great influence of free liquid surface, and low water inlet angle, so as to improve safety performance and influence The effect of reducing and lowering the height of the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

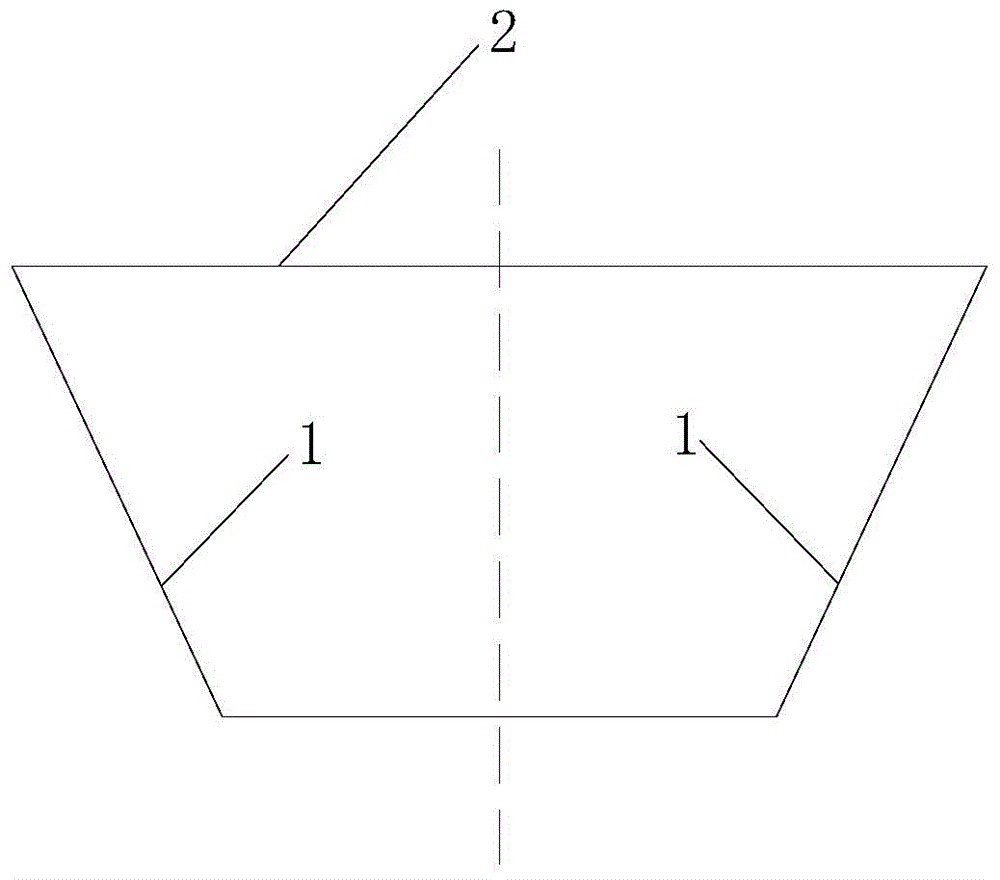

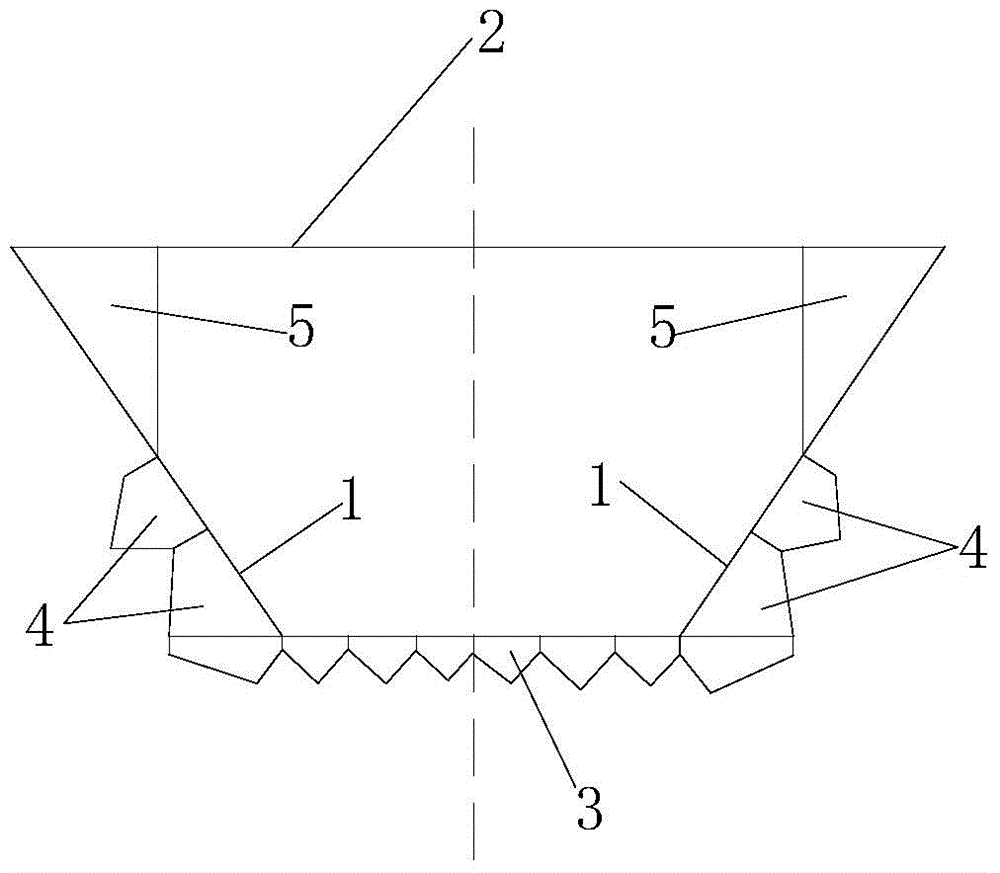

[0027] Such as figure 2 As shown, the tumbler ship type of the present embodiment includes a trapezoidal hull made of an outer shell 1 and a deck 2, the bottom of the hull is provided with a ballast tank 3, and the lower part of the outer shell 1 is provided with a hopper tank 4, A topside tank 5 is provided on the upper part of the shell 1 .

[0028] The tumbler ship type of this embodiment has increased the bottom ballast tank 3, effectively reduced the height of the center of gravity of the ship; due to the increase of the displacement volume of the ship, the freeboard is increased, and the height of the water inlet angle is relatively increased; the free liquid surface is at 5%. The area moment at the ten points is relatively reduced, so the influence of the free liquid surface is reduced; thus the ship tends to be more stable and balanced, and the safety performance is greatly improved.

[0029] The tumbler ship type of this embodiment is especially suitable for the tra...

Embodiment 2

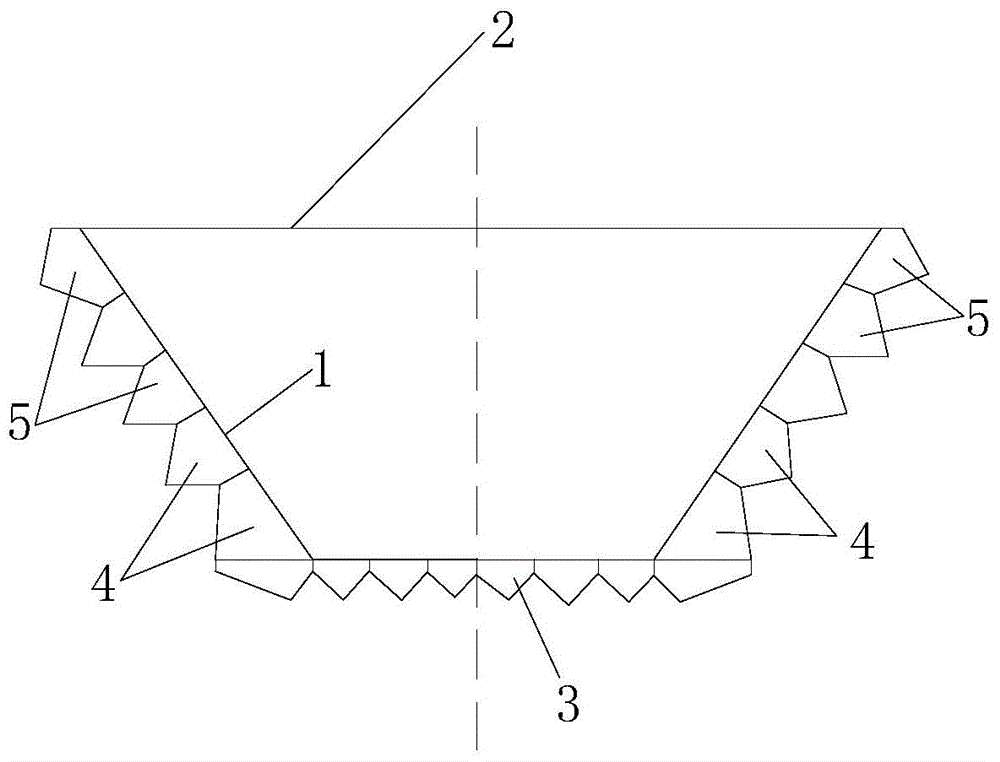

[0032] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that: the ballast tank 3 is arranged on the outside of the bottom of the hull, the hopper tank 4 is arranged on the outside of the lower part of the shell 1, and the topside tank 5 is arranged on the outside of the shell 1 outside of the upper part. The ballast tank 3, the hopper tank 4 and the topside tank 5 are all arranged on the outside of the hull. On the one hand, it is beneficial to protect the hull shell 1 from collision damage. Transportation of goods. The ballast tank 3, the hopper tank 4 and the topside tank 5 are all arranged outside the hull, which helps to protect the hull shell 1 from collision damage on the one hand, and does not occupy the interior space of the cabin on the other hand.

[0033] As preferably, the ballast tank 3, the hopper tank 4 and the topside tank 5 are all hemmed, and the hemmed ballast tank 3, the hopper tank 4 and the topside tank 5 are conduci...

Embodiment 3

[0035] Such as Figure 4 As shown, the tumbler ship type of this embodiment also includes a balance cabin 6, which is arranged at the bottom of the hull, and the balance cabin 6 can be used separately or in combination with the hull cabin, which not only can increase the cabin volume of the hull, but also The center of gravity of the hull is effectively reduced, the displacement volume of the hull is increased, the freeboard is increased, and the angle of water entry is relatively increased, which greatly improves the stability and safety performance of the hull.

[0036] Wherein, the ballast tank 3, the hopper tank 4 and the topside tank 5 are straight-sided, the ballast tank 3 is arranged at the bottom of the balance tank 6, the two sides of the balance tank 6 and the shell 1 The lower part is provided with hopper tanks 4, which helps to protect the hull shell 1 from collision damage, and the top of the shell 1 is provided with topside tanks 5, which reduces the weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com