Production apparatus and manufacturing method of fiber-reinforced ring

A technology of fiber reinforcement and production equipment, which is applied in the field of fiber reinforcement rings for cryogenic containers and its manufacturing, can solve the problems of high price of winding machines, achieve the effects of improving bridges and cavities, improving performance, and reducing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

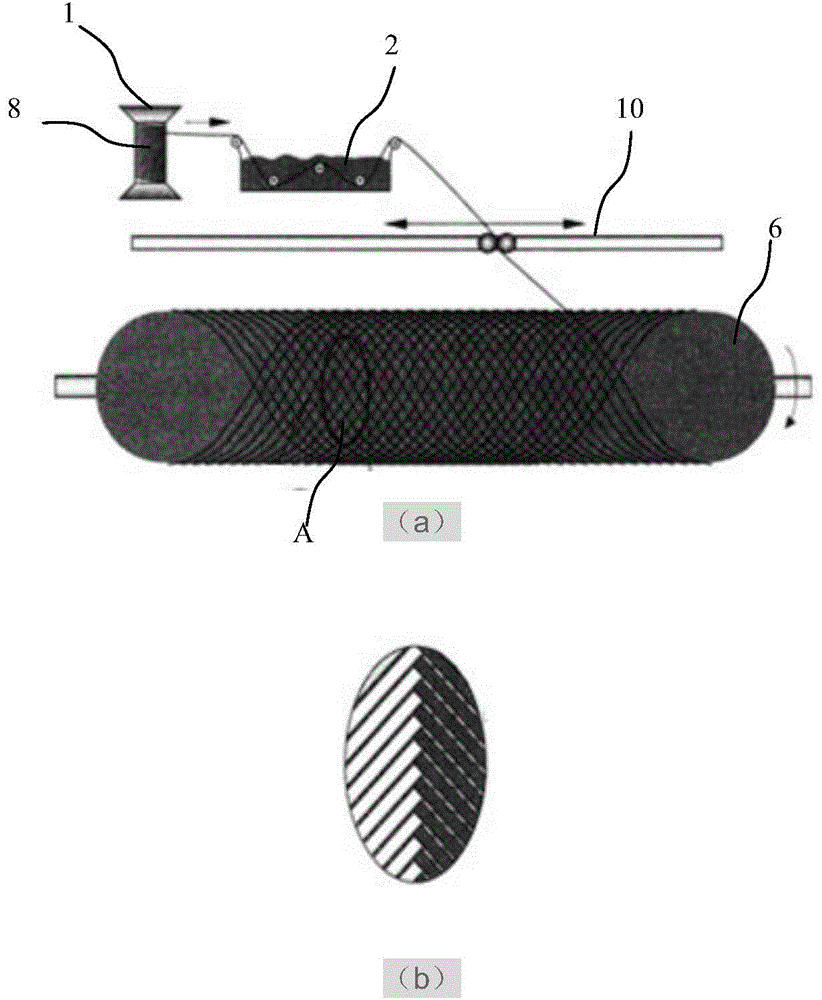

[0048] Figure 7 It is a structural schematic diagram of a production device for a fiber reinforced ring in an embodiment of the present invention.

[0049] See Figure 7 , the production device of the fiber-reinforced ring provided by the present invention includes: a yarn twisting shaft 1, a dipping pool 2, a wire winding mouth 3, a tensioning device 4, a flattening device 5, a mandrel 6 and a driving System 7, the mandrel 6 is connected to the driving system 7 through the first transmission belt 71, the yarn twisting shaft 1, the winding nozzle 3, the tensioning device 4 and the flattening device 5 are arranged in sequence for the roving twist 8 to pass through to become a flat yarn twist 9.

[0050] Figure 8 It is a structural schematic diagram of the round inlet of the winding nozzle in the production device of the fiber reinforced ring in the embodiment of the present invention; Figure 9 It is a schematic cross-sectional view of a rectangular inlet winding nozzle i...

Embodiment 2

[0060] The difference from Embodiment 1 is that this embodiment is dry winding, that is, the early winding process does not impregnate the resin, and after the winding is completed, the resin is injected into the core mold 6 by vacuum filling, and then dried and formed. That is, there is no dipping tank 2 in the production device of the fiber reinforced ring provided in this embodiment, and the roving twist 8 is pulled out from the yarn twist shaft 1 and directly passes through the through hole 31 of the winding nozzle 3 to become a flat yarn twist 9; After the flat yarn twist 9 is wound, the resin is injected into the mandrel 6 by means of vacuum filling, which is formed naturally or dried, and the fiber-reinforced ring is formed after demoulding.

[0061] Compared with the existing technology, Figure 4 In the existing yarn-twist layered structure shown in , the inside of the yarn-twist may be impregnated with resin glue, Figure 12 In the fiber yarn tape layered structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com