Clamping unit of a molding machine and method for monitoring the clamping unit of a molding machine

A molding machine and molding mold technology, which is applied in the field of monitoring the clamping unit of the molding machine, can solve the problems of cumbersome structure and the inability to compensate the deviation of the lower mold, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

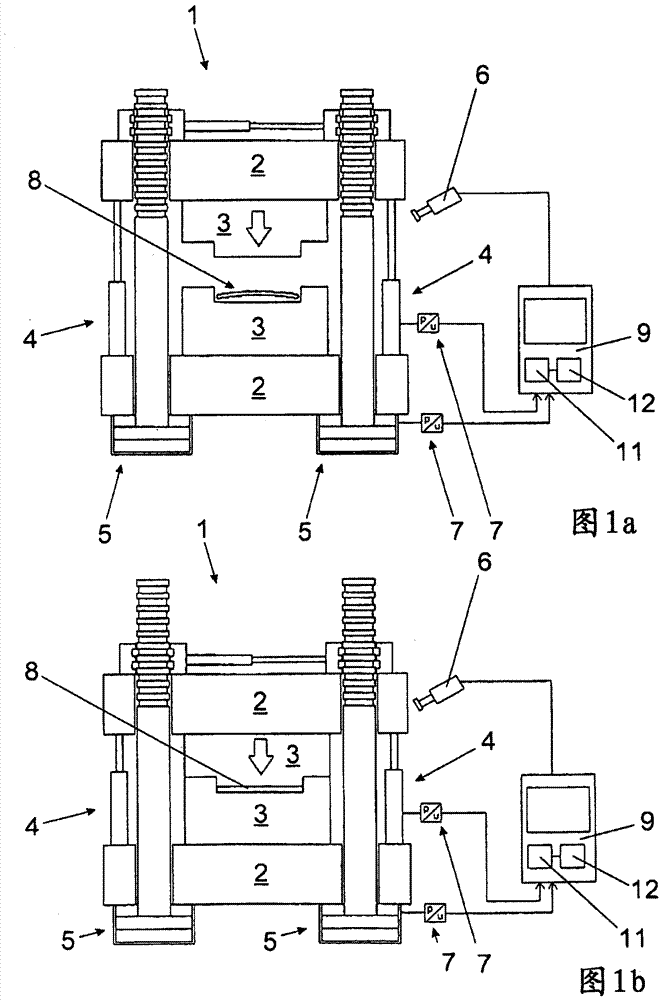

[0037]The clamping unit 1 is shown in FIGS. 1 a and 1 b. The mold clamping unit comprises two clamping plates 2 on which the components of the forming mold 3 are installed respectively. In addition, two fast-stroke drives 4 and four power-stroke drives 5 are respectively provided, which allow high pressing forces to be applied to the mold 3 . (Due to the manner of presentation, only two of the four power stroke drives 5 are visible.) The exact design of the clamping unit 1 is not important for the invention. The hydraulic clamping unit 1 shown here is therefore only exemplary with four longitudinal beams. Likewise, clamping units with frames can be used, for example, with electronic crank lever machines or other hybrids. Furthermore, it is not important for the invention whether a horizontal or vertical clamping unit is used.

[0038] FIG. 1 a shows the clamping unit 1 after the semi-finished product 8 , in this case a fiber fabric, has been placed in the mold 3 . The clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com