Pressurized pack for viscous materials

A point of action, distributor technology, applied in the direction of injection device, injection device, distribution device, etc., can solve the problems of injury, difficult to replace the nozzle, unable to ensure safe work, etc., to achieve the effect of reliably guiding the distributor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

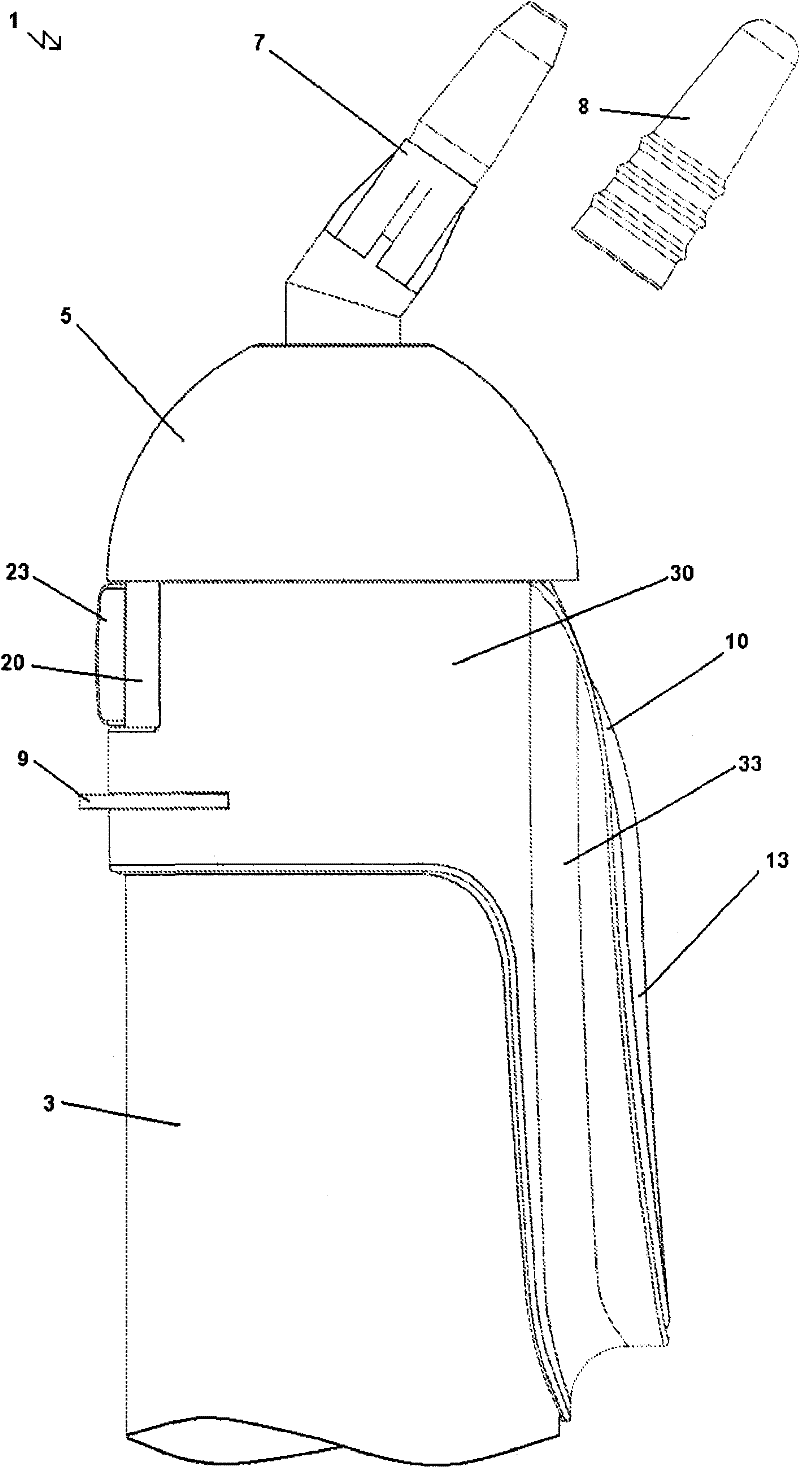

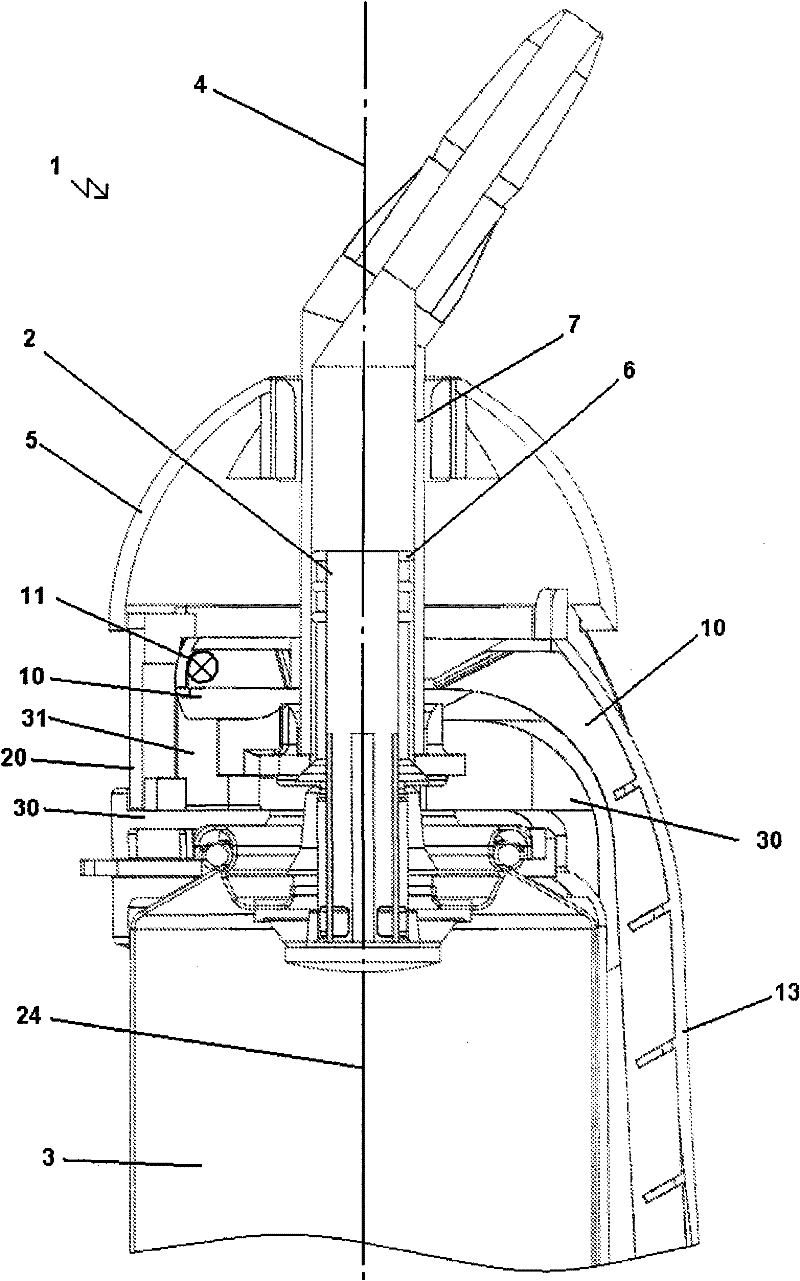

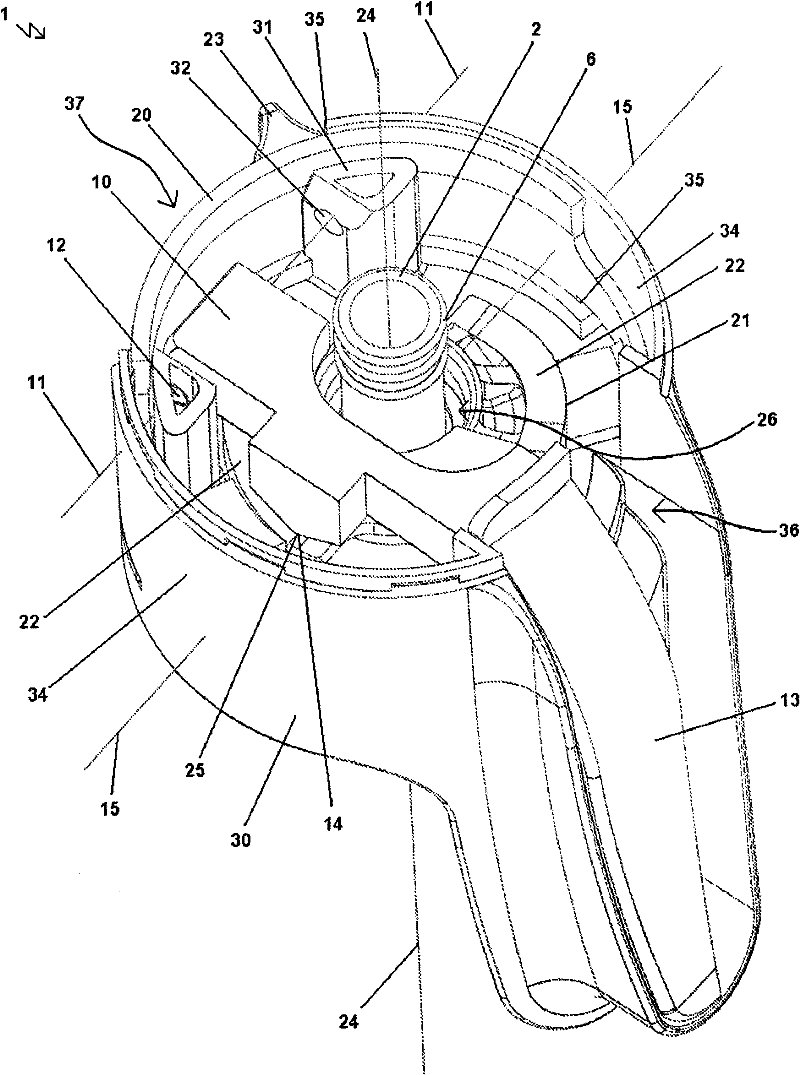

[0027] Figure 1-6 A dispenser 1 according to the invention is shown for dispensing a product from a cylindrical container 3 with a container axis 4 . The container 3 is in this case configured as a pressurized container. Metals such as aluminum or tin are suitable as materials for this type of construction. It goes without saying that other suitable materials can also be used. Arranged adjacent to the container 3 is a valve 2 for discharging the product present in the container 3 via a nozzle 7 . For this purpose, the nozzle 7 can be connected via the connecting means 6 to the side of the valve 2 facing away from the container 3 . The outlet opening of the nozzle 7 can be covered by means of a cap 8 in order to protect the nozzle 7 and the valve 2 from soiling.

[0028] In this embodiment, a butterfly valve known from the prior art is used as the valve 2 . Such valves 2 are generally known in distributors 1 and function by turning over a hollow central spindle, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com