Metal plate oxide skin removal equipment

A technology of oxide skin and metal plate, which is applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of cumbersome oxide skin removal processing steps, high equipment cost, complex structure, etc., to reduce the overall cost and reduce the Simple and reasonable effect of operating cost and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

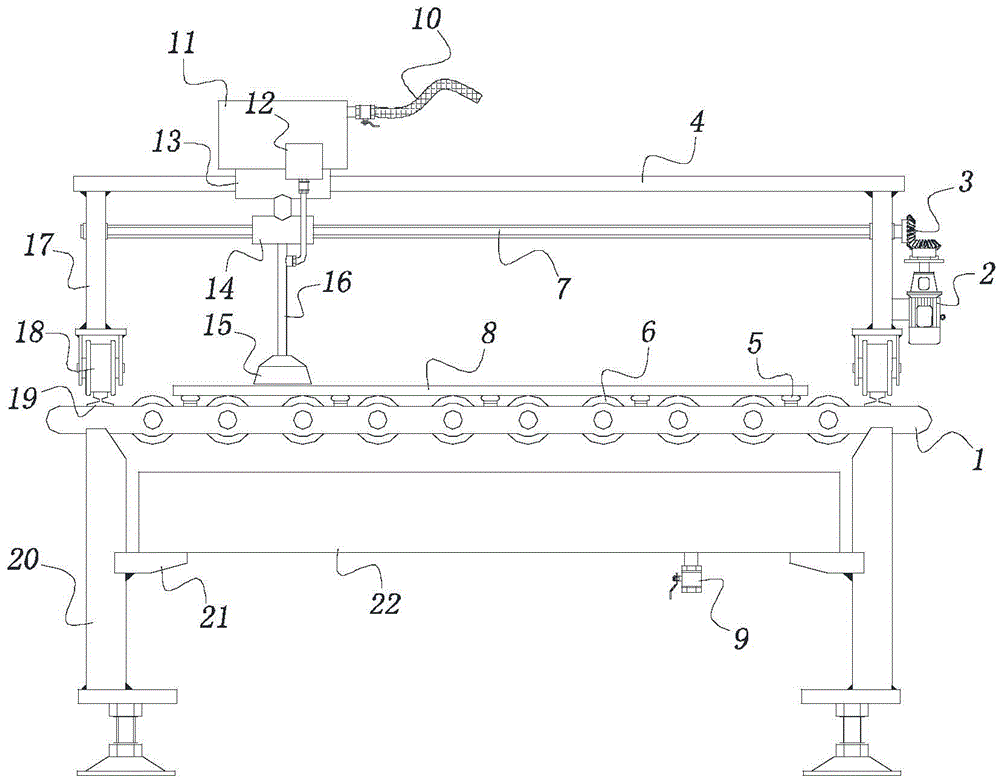

[0012] See figure 1 , the present invention includes two opposite side plates 1 supported by a plurality of uprights 20 , and a plurality of idler rollers 6 of equal height are installed between the two side plates 1 for stably supporting the sheet metal 8 . The metal plate 8 can be pushed in laterally from the head end or the tail end, and a driving machine can also be configured for the above-mentioned idler roller 6 in actual construction to provide a certain auxiliary feeding capacity to reduce labor intensity.

[0013] A guide rail 19 is erected and fixedly connected between the head end and the tail end of the two side plates 1 , and the length direction of the guide rail 19 is parallel to the axial direction of each supporting roller 6 .

[0014] Also comprise the mobile frame that is made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com