Assembly jig and assembly method for motor transmission ring

A technology for assembling fixtures and transmission rings, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of transmission ring life impact, transmission ring damage, etc., and achieve the effect of simple and scientific structural design and convenient assembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

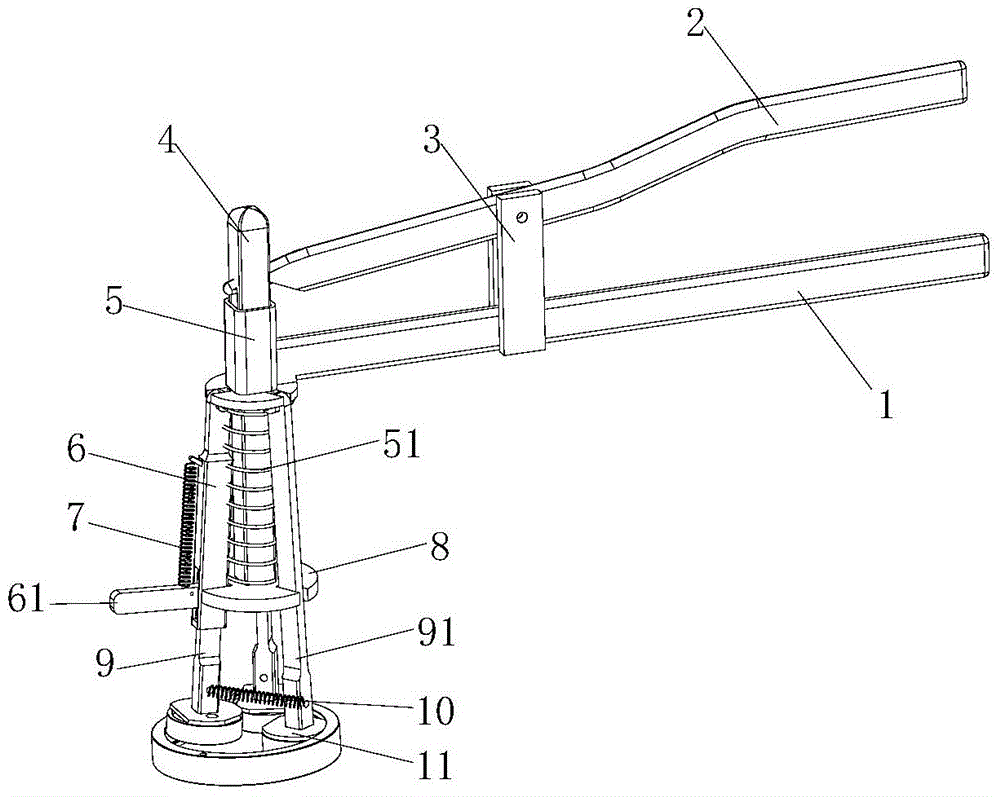

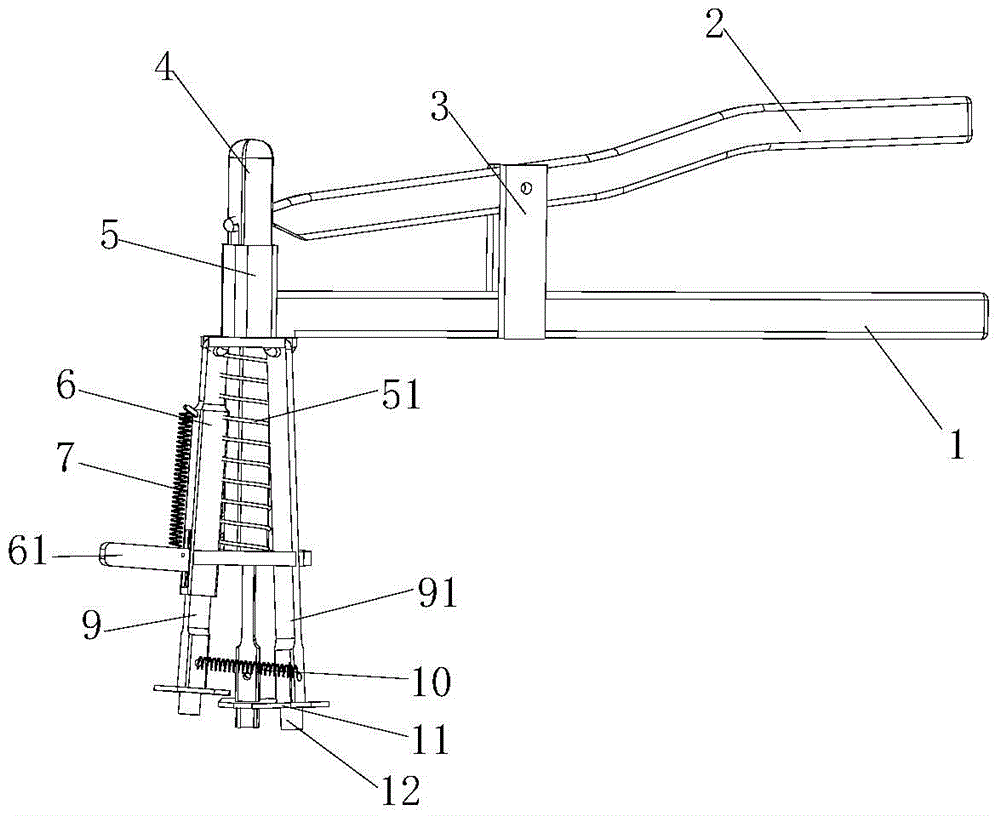

[0023] See Figure 1 to Figure 6 As shown: the present invention includes a fixed handle 1, a movable handle 2, a center rod 4, a fixed rod sleeve 5, a pressure rod sleeve 6, a support plate 8, and a pressure rod 9, and the fixed handle 1 and the movable handle 2 are hinged through a support rod 3 , one end of the movable handle 2 is movably connected to the central rod 4, and the central rod 4 is movably plugged into the fixed rod sleeve 5, and the fixed rod sleeve 5 is connected to one end of the fixed handle 1, and the movable hinge on the fixed rod sleeve 5 is provided with Depression bar 9, movable strut 91, is provided with depression bar sleeve 6 on the depression bar 9, and movable strut 91 is two, is provided with movable support plate 8 between movable support bar 91, depression bar 9, and support plate 8 It is connected with the central rod 4, a return spring 51 is provided between the support plate 8 and the central rod 4, a pressure rod handle 61 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com