Method for locating roll-gap-opening no-load channeling roll of UCM rolling mill

A positioning method and roll shifting technology, which is applied in the field of roll shifting positioning in rolling mills, can solve the problems of extra production time, complicated roll shifting operation, difficult adjustment of plate shape, etc., and achieve flexible rolling production, simplified roll shifting operation, and good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below with reference to the accompanying drawings.

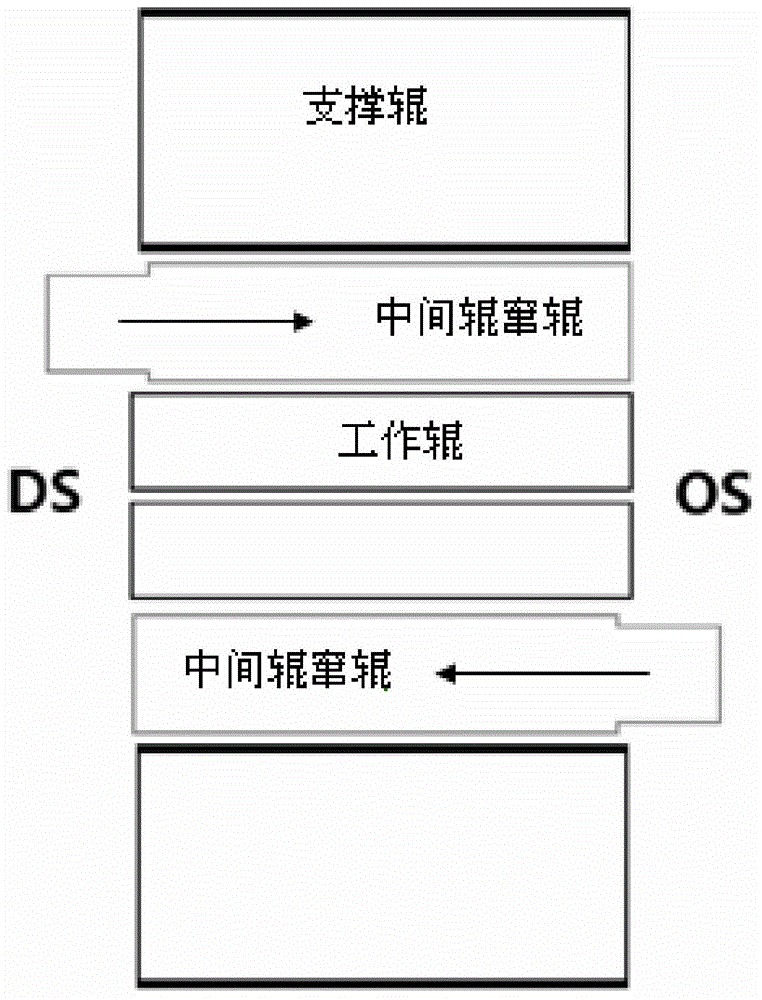

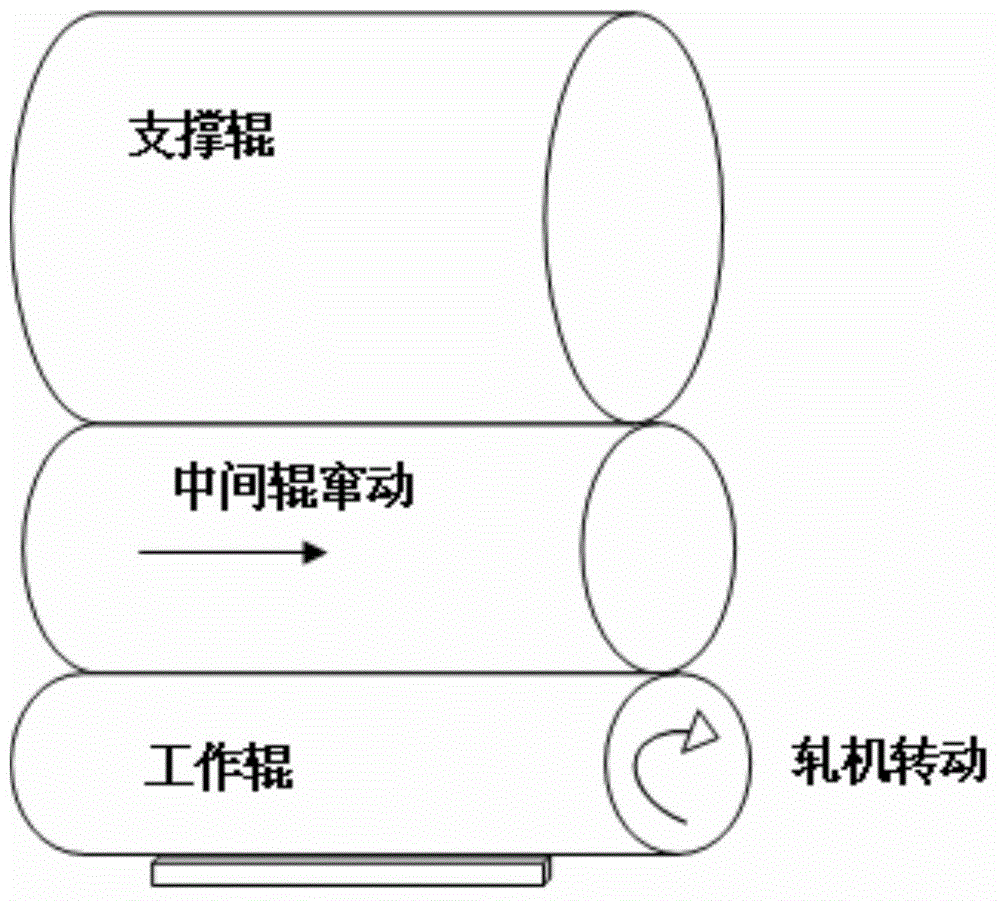

[0025] A method for locating roll shifting with no load when opening a roll gap of a UCM rolling mill, comprising the following steps:

[0026] 1) The HGC hydraulic roll gap control system of the rolling mill is turned on, so that the roll gap between the upper work roll and the lower work roll maintains the roll gap state when the roll gap is opened, the bending force of the work roll is set to the maximum value, and the middle roll bends The roller force is set as a balance force;

[0027] 2) Mill speed V w Raise to the predetermined speed, after the predetermined speed stabilizes, move the intermediate roll according to the roll shift value, the roll shift speed of the intermediate roll is Vs, until the axial position of the roll reaches the set roll shift value;

[0028] 3) The roll shifting of the intermediate roll reaches the roll shifting value, and after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com