Emulsification reaction system

A reaction system and a reaction kettle technology, applied in the field of emulsification reaction system, can solve the problems of occupying the inner space of the kettle body, inconvenient installation, air pollution, etc., and achieve the effects of good stirring effect, simple structure and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

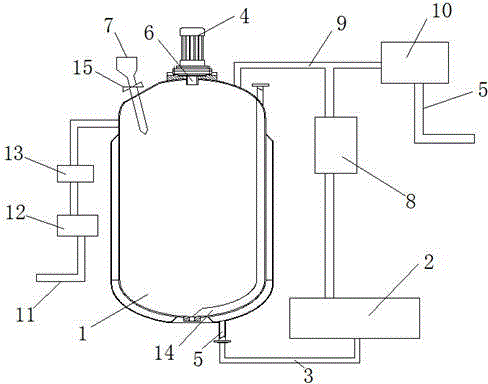

[0018] See figure 1 , the present invention reactor 1, emulsifying machine 2 and output pipeline 3; Reactor 1 upper end is installed with emulsifying motor 4, and lower end surface is provided with discharge opening 5; Emulsifying motor 4 is connected with stirrer 6; The two ends are respectively connected with the output pipe 3 and the discharge port 5; there is also a static condenser 8;

[0019] There is also a first filter 10; the first filter 10 is connected in series at the outlet of the discharge pipe 9.

[0020] A feed pipe 11 is connected to the reaction kettle 1; a pressure gauge 12 and a second filter 13 are connected in series on the feed pipe 11 in sequence.

[0021] There is an extruding pipe 14 inside the reaction kettle 1; the extruding pipe 14 is arranged close to the inner wall of the reaction kettle 1, and the entrance of the extruding pipe 14 is an oblique opening.

[0022] The upper part of the reaction kettle 1 has an additive funnel 7 connected through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com