A kind of feed material and its preparation and application

A feed raw material and biodegradation technology is applied in the field of feed raw material and its preparation and application, which can solve the problems of the spread of animal diseases, the disease of livestock and poultry, and the death of livestock and poultry, so as to improve the living environment and have high nutritional value. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of Meat and Bone Meal:

[0026] The purified Bacillus subtilis, Candida utilis and wheat bran were mixed and cultured at 50°C for 4 hours in a closed reaction tank. After culturing, dead pigs were added and biodegraded at 70°C under crushing and stirring conditions for 24 hours. The remaining wheat bran is added to it, and the degradation product obtained by biodegradation is sterilized and dried at 110°C for 20 hours, and then steam-dried at 250°C for 20 minutes after sterilization. (2.5mm) to get meat and bone meal.

[0027] Among them, the mass ratio of dead livestock and poultry to wheat bran is 5:1; biodegradation bacteria account for 1 / 1000 of the total amount of dead livestock and poultry and wheat bran.

[0028] The purified Bacillus subtilis is obtained by transferring the commercially available Bacillus subtilis to the slant of beef extract peptone medium, cultured at a constant temperature of 37° C. for 48 hours, and set aside.

[0029] The puri...

Embodiment 2

[0032] Preparation of Meat and Bone Meal:

[0033] The purified Bacillus subtilis, Candida utilis and wheat bran were mixed and cultured at 55°C for 7 hours in a closed reaction tank. After culturing, dead chickens were added to biodegrade at 60°C under crushing and stirring conditions for 20 hours. The remaining wheat bran is added to it, and the biodegraded degradation products are sterilized and dried at 115°C for 24 hours, and then steam-dried at 300°C for 25 minutes. After drying, keep the temperature constant (300°C) and press for 20 minutes. (2.5mm) to get meat and bone meal.

[0034] Among them, the mass ratio of dead livestock and poultry to wheat bran is 5:1; biodegradation bacteria account for 1 / 1000 of the total amount of dead livestock and poultry and wheat bran.

Embodiment 3

[0036] Preparation of Meat and Bone Meal:

[0037] The purified Bacillus subtilis, Candida utilis and wheat bran were mixed and cultured at 55°C for 5 hours in a closed reaction tank. After culturing, dead pigs were added and biodegraded at 65°C under crushing and stirring conditions for 22 hours. At the same time, the The remaining wheat bran was added to it, and the biodegraded degradation product was sterilized at 105°C for 20 hours, then steam-dried at 240°C for 30 minutes after sterilization, kept at the same temperature (240°C) for 20 minutes after drying, crushed and sieved ( 2.5mm) to get meat and bone meal.

[0038] Among them, the mass ratio of dead livestock and poultry to wheat bran is 6:1; biodegradation bacteria account for 1 / 500 of the total amount of dead livestock and poultry and wheat bran.

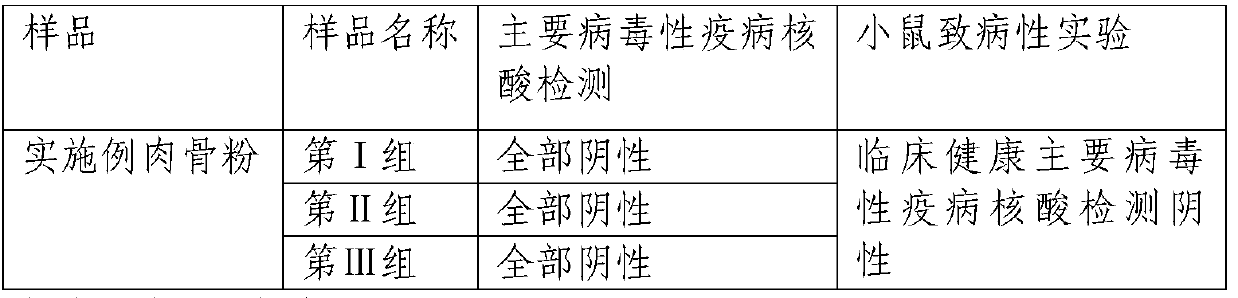

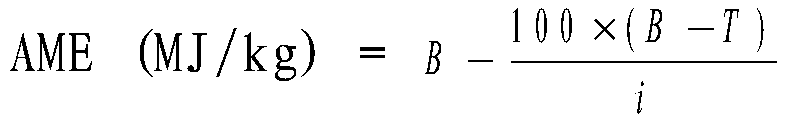

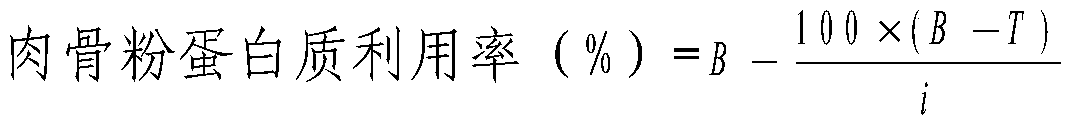

[0039] Carry out corresponding detection and application to above-mentioned each embodiment gained meat and bone meal, be specially:

[0040] 1. Detection of quality a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com