Substrate plating jig

A substrate and fixture technology, which is applied in the fields of electrical components, electrolysis process, semiconductor/solid-state device manufacturing, etc., can solve the problems of large number of parts, complicated replacement of seals, and high cost, and achieve uniform plating liquid flow and easy replacement operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, embodiment of the plating jig of this invention is demonstrated concretely based on drawing. In addition, the present invention is not limited to these embodiments.

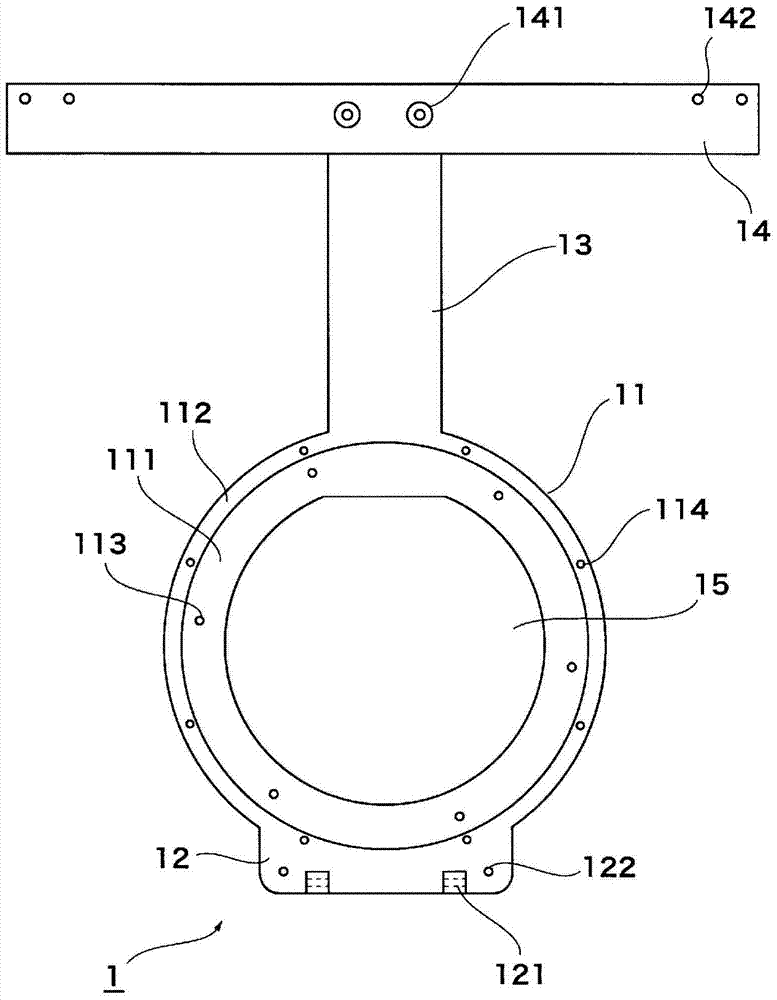

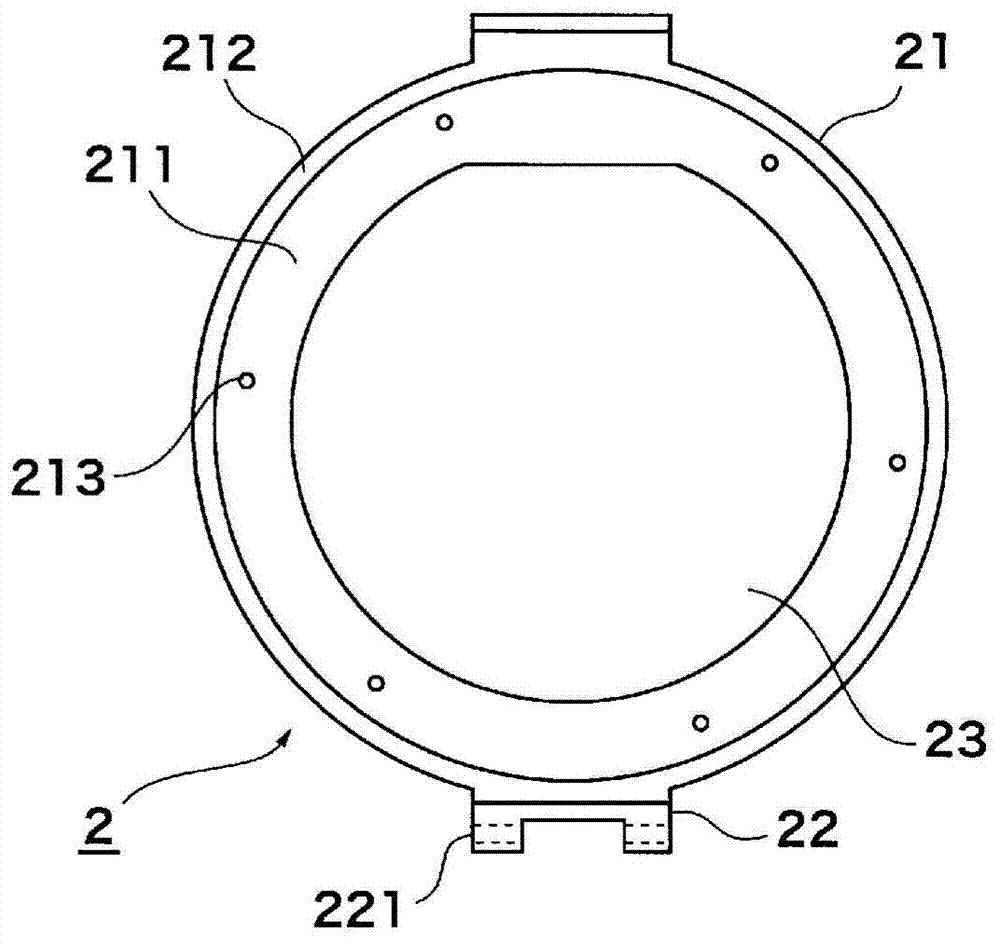

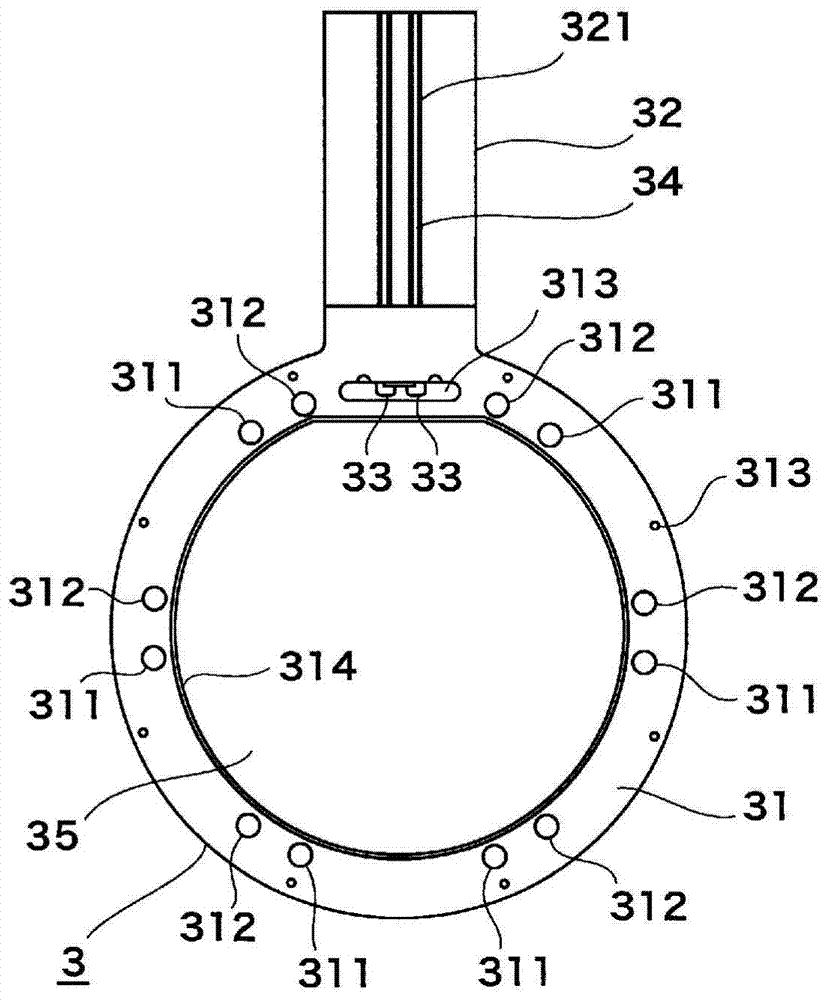

[0023] figure 1 It is the front view of the base part of the plating jig of the present invention, figure 2 It is the front view of the cover part of the plating jig of the present invention, image 3 It is a front view of the central part of the plating jig of the present invention, Figure 4 It is the front view of the clamp part of the plating jig of the present invention, Figure 5 It is a front view of the gasket 5 in a state where the energization ring 6 is arranged inside, Image 6 It is a front view of the state where the clamp part 4 and the cover part 2 are opened after the plating jig of the present invention is assembled, Figure 7 It is a partially enlarged cross-sectional view of a state in which the substrate W is held by the plating jig of the present invention.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com