Aluminum alloy conductor, alum1inum alloy stranded wire, sheathed wire, wire harness, and method for manufacturing aluminum alloy conductor

A technology for aluminum alloy conductors and manufacturing methods, which is applied in the direction of metal/alloy conductors, cable/conductor manufacturing, and used to reduce the size of conductors/cables, etc., and can solve the problem of limited use positions, low operating efficiency, and inability to withstand impacts, etc. problems, achieve the effect of reducing disconnection and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

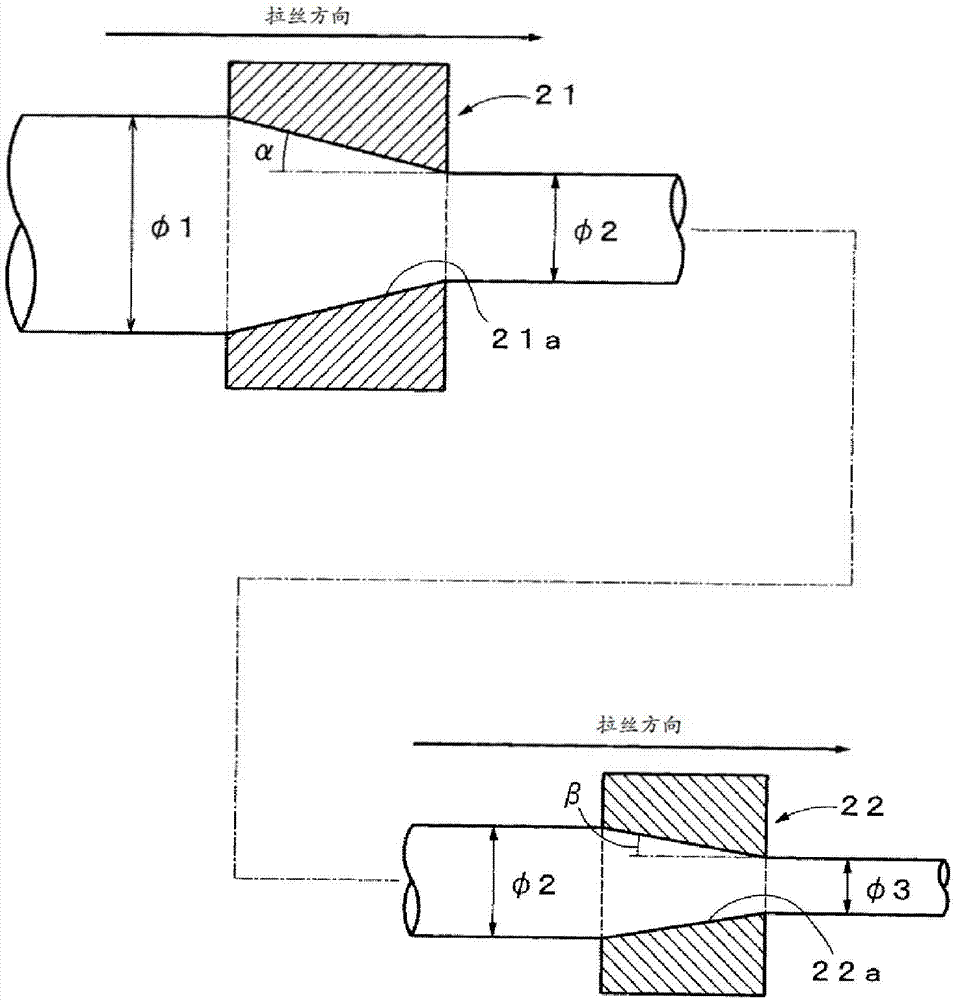

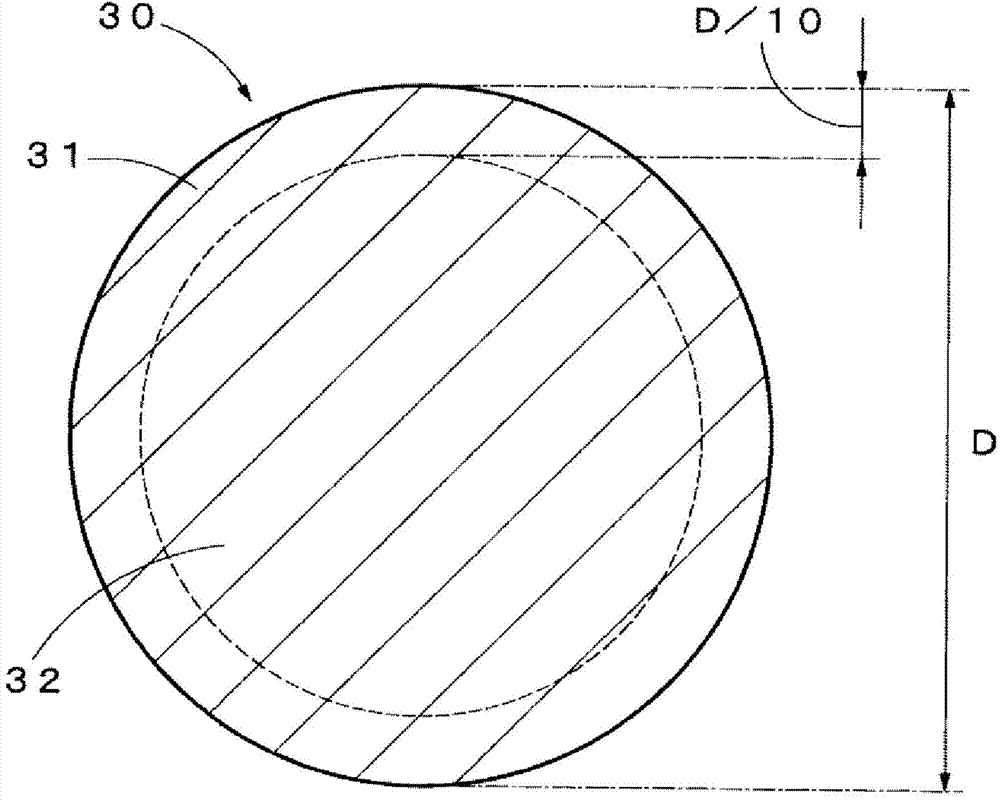

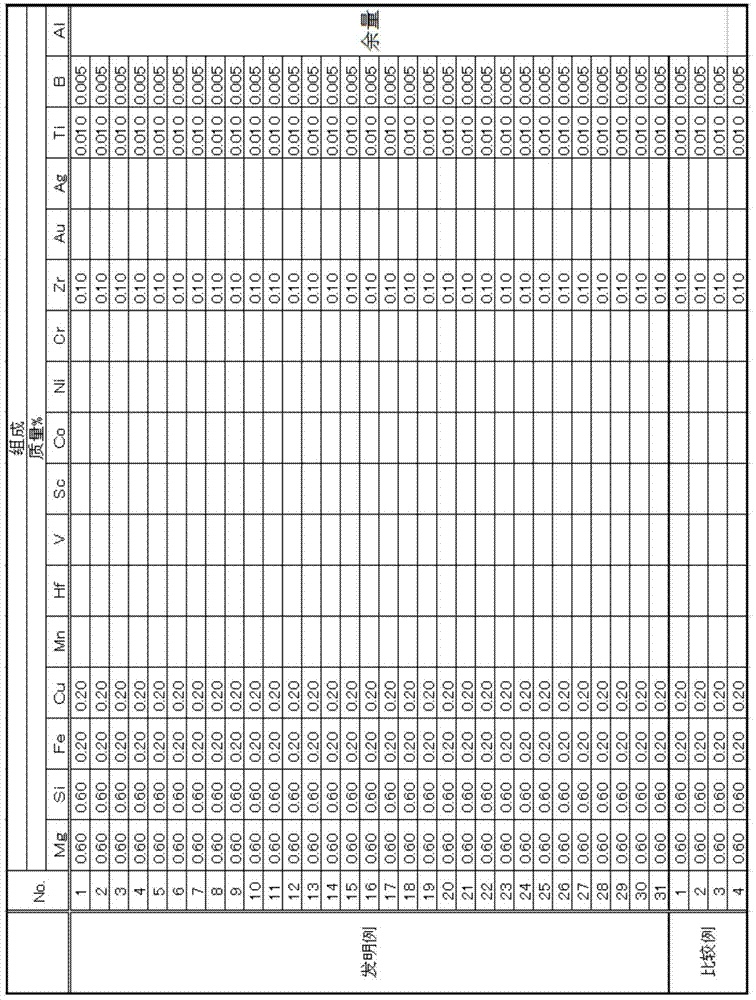

[0104] Mg, Si, Fe, and Al, and optionally added Cu, Zr, Ti, and B were set to the contents (mass %) shown in Table 1, using a Propezer-type continuous casting and rolling machine, while utilizing water-cooled casting The mold continuously casts molten metal and rolls it to make approx. of bars. The casting cooling rate at this time is 1 to 20°C / sec. Next, the first wire drawing was performed so that the processing rates shown in Table 2 were obtained. Then, intermediate heat treatment is performed on the processed material subjected to the first wire drawing, and thereafter, the second wire drawing is performed at the same processing rate as the first wire drawing. the wire diameter. Then, solution heat treatment (first heat treatment) was performed under the conditions shown in Table 2. It should be noted that, in the solution heat treatment, when the batch type heat treatment is used, a thermocouple is wound around the wire rod to measure the temperature of the wire ro...

Embodiment 2

[0106] Mg, Si, Fe, and Al, and optionally added Cu, Mn, Cr, Zr, Au, Ag, Hf, V, Ni, Sc, Co, Ti, and B are the contents shown in Table 3 (mass %) Cooperate, in addition, carry out casting, rolling by the method identical with embodiment 1, make approximately of bars. Next, the first wire drawing was performed so that the processing rates shown in Table 4 were obtained. Then, intermediate heat treatment is performed on the processed material subjected to the first wire drawing, and thereafter, the second wire drawing is performed at the same processing rate as the first wire drawing. the wire diameter. Then, solution heat treatment (first heat treatment) was performed under the conditions shown in Table 4. After the solution heat treatment, aging heat treatment (second heat treatment) was performed under the conditions shown in Table 4 to manufacture aluminum alloy wires.

[0107] Each characteristic was measured by the method shown below about the produced aluminum alloy w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com