Filler-containing silicone compositions

A technology of organosilicon compounds and compositions, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of not being effective enough, unfavorable damping characteristics, uneven filler distribution, etc.

Inactive Publication Date: 2015-07-15

WACKER CHEM GMBH

View PDF5 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the solutions presented in the above-mentioned documents, where pure metal surfaces are used, are still not sufficiently effective because only the relatively small effective surface area of the metal is available for the reaction to intercept sulfur-containing gases

There are also many other disadvantages associated with this solution, such as high price, high density, and unfavorable damping characteristics

A particularly disadvantageous factor is the sedimentation of metal-containing fillers in silicone compositions, which leads to inhomogeneous filler distribution

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

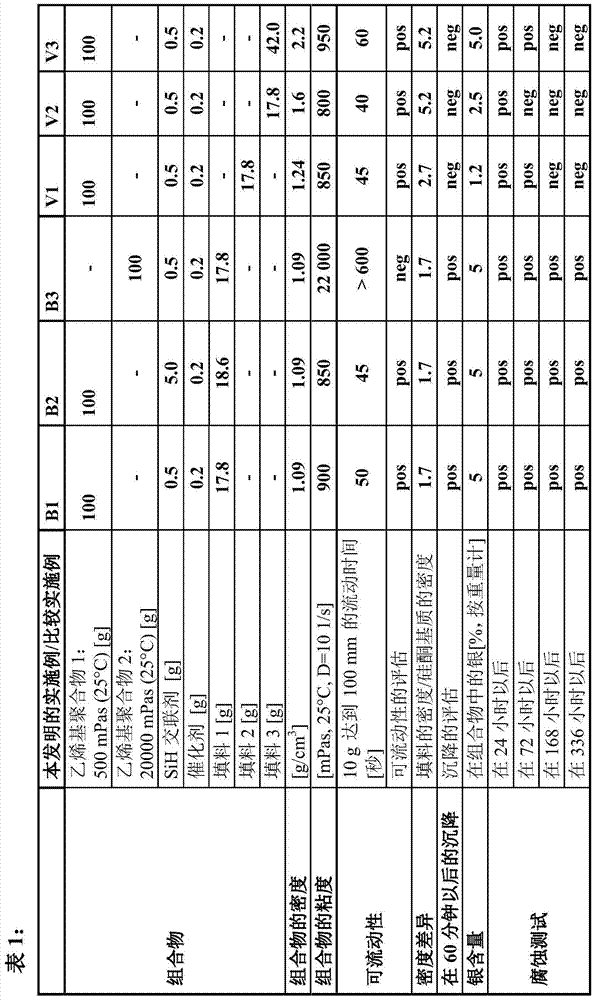

[0111] Silicone composition with filler consisting of hollow glass microspheres and metallic silver coating (with low density) and high viscosity silicone polymer.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention describes novel addition-crosslinking silicone compositions containing: (1) organosilicon compounds having radicals with aliphatic carbon-carbon multiple bonds; (2) organosilicon compounds with Si-bound hydrogen atoms; (3) the accumulation of Si-bound hydrogen at catalysts promoting aliphatic multiple bonding; and (4) as filler, silicate hollow glass micro-balls with a silver coating, wherein more than 95 wt% of the silver applied to the hollow glass micro-balls is present as metallic silver.

Description

technical field [0001] The present invention relates to filled addition-crosslinking silicone compositions which allow, inter alia, the protective encapsulation of electrical and electronic components exposed to highly corrosive environments. Background technique [0002] Silicone casting compositions are widely used to protect electronic circuits from corrosion. Today, electronic components are also increasingly exposed to particularly aggressive and harmful sulfur-containing gases. Silicone casting compositions available to date have high permeability to sulfur, hydrogen sulfide, sulfur dioxide, carbon disulfide, and other organosulfur compounds, and the resulting corrosion of metal conductor tracks leads to failure and shortened life of these components. [0003] EP 1 295 905 A1 describes silicone encapsulating compositions which contain metal powders as fillers, for example powders consisting of silver, copper, iron, nickel, aluminium, tin, and zinc, copper powder being...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D183/04C08K3/40C08K3/08

CPCC09D183/04C08K9/02C08G77/38C08G2150/90C08K2201/003C09D5/08

Inventor 菲利普·米勒

Owner WACKER CHEM GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com