Energy-saving type motor control system

A motor control and control system technology, applied in the electronic field, can solve the problems of high energy consumption and achieve the effects of reducing failure rate, avoiding damage, and avoiding voltage shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

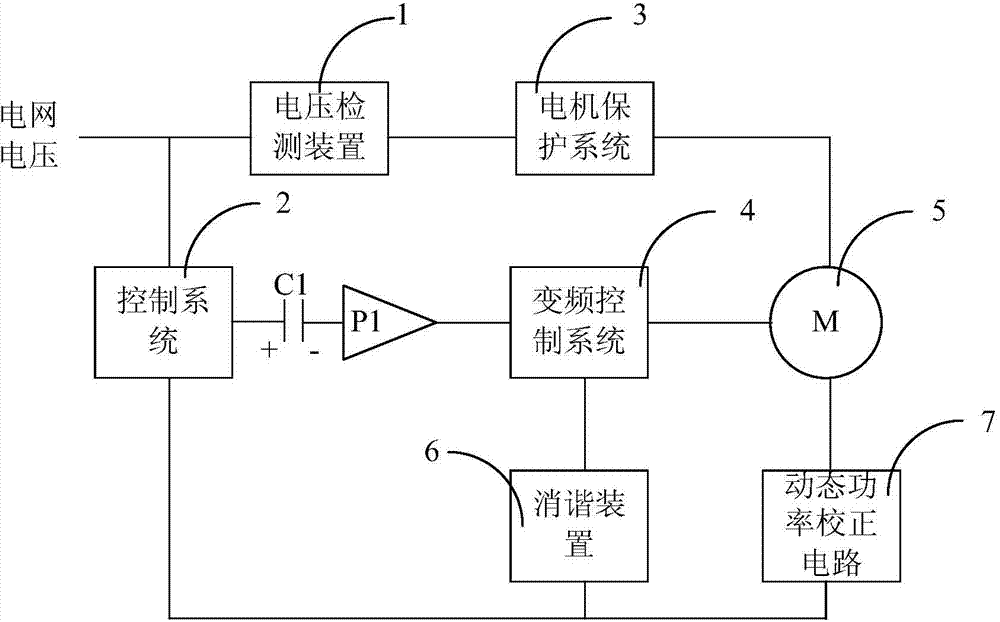

[0021] Such as figure 1 As shown, the present invention consists of a motor 5, a control system 2, a voltage detection device 1 connected with the control system 2, a motor protection system 3 connected with the voltage detection device 1, a frequency conversion control system 4 connected with the motor 5 and a dynamic It consists of a power correction circuit 7 and a harmonic elimination device 6 connected with the frequency conversion control system 4 .

[0022] In order to better realize the purpose of the present invention, the motor protection system 3 is also connected with the motor 5, and the control system 2 is connected with the external power grid, and the frequency conversion control system 4 is connected with the control system 2 after passing through the amplifier P1 and the capacitor C1 in sequence. Connection, that is, after the external voltage is output by the control system 2, it is filtered by the capacitor C1 and amplified by the amplifier P1, and then sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com