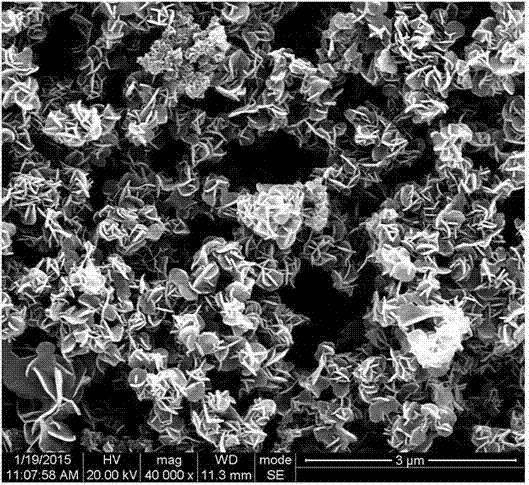

Supercapacitor using nickel aluminum hydrotalcite nanometer material as anode material

A nickel-aluminum hydrotalcite and supercapacitor technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of low energy density, achieve the effect of improving reaction rate, long cycle life, and improving contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

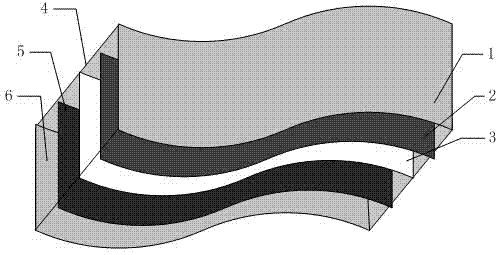

[0048] The assembled device structure is as figure 2 As shown, the assembly of the positive electrode material and the positive electrode current collector is to mix the prepared nano-flower-shaped nickel-aluminum hydrotalcite, carbon black and binder at a mass ratio of 80:15:5 and then coat it on the foamed nickel current collector. The thickness is 10-50um. The assembly of the negative electrode material and the negative electrode current collector is to coat the activated carbon material on the nickel foam current collector, and the coating thickness is 10-50um. Separate the assembled positive and negative electrodes with an electrode separator and place them in KOH electrolyte for soaking, and finally assemble them into a battery. The constant current discharge curve is as follows: image 3 shown.

[0049] Depend on image 3 As can be seen from the constant current discharge curve of the supercapacitor of the present invention, the discharge curve of the supercapacitor...

Embodiment 2

[0067] The assembled device structure is as figure 2 As shown, the assembly of the positive electrode material and the positive electrode current collector is to mix the prepared three-dimensional nano-flower-shaped nickel-aluminum hydrotalcite, nano-graphene and binder at a mass ratio of 75:20:5 and then coat it on the foamed nickel current collector. Coating thickness is 10-50um. The assembly of the negative electrode material and the negative electrode current collector is to coat the activated carbon material on the nickel foam current collector, and the coating thickness is 10-50um. The assembled positive electrode and negative electrode are separated by an electrode separator, placed in KOH electrolyte for soaking, and finally assembled into a battery.

[0068] The preparation process is similar to Example 1.

Embodiment 3

[0070] The assembled device structure is as figure 2 As shown, the assembly of the positive electrode material and the positive electrode current collector is to mix the prepared nickel-aluminum hydrotalcite, carbon nanotubes and binder at a mass ratio of 85:10:5 and then coat it on the foamed nickel current collector. The coating thickness It is 50um. The assembly of the negative electrode material and the negative electrode current collector is to coat the activated carbon material on the nickel foam current collector, and the coating thickness is 50um. The assembled positive electrode and negative electrode are separated by an electrode separator, placed in KOH electrolyte for soaking, and finally assembled into a battery.

[0071] The preparation process is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com