Heat insulation type wire insulation shield

A wire insulation and shielding cover technology, which is applied in the direction of insulated cables, insulated conductors, conductors, etc., can solve the problem that ordinary wire insulation shielding covers cannot meet the needs of live work on grounding pole lines, and achieve isolation from the influence of insulating materials and operators , Reinforced stability, easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

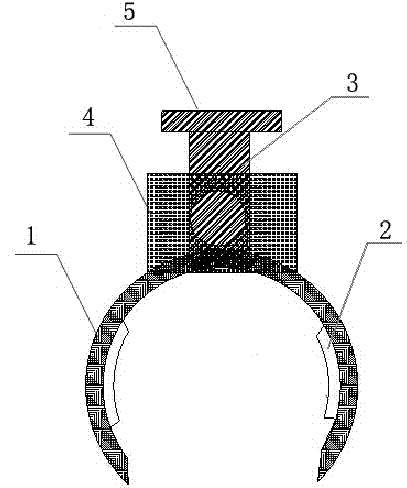

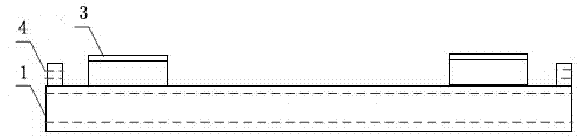

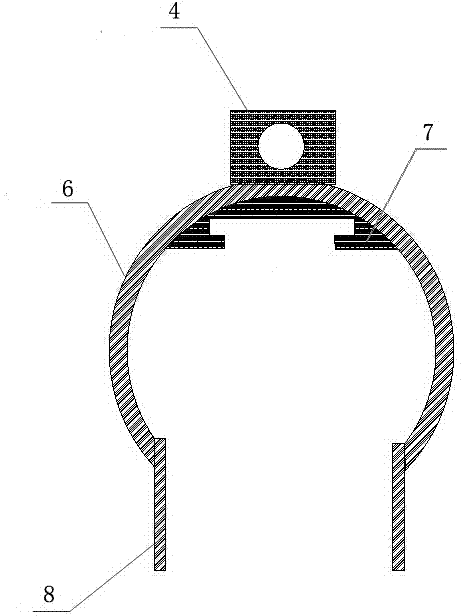

[0020] Such as Figure 1 to Figure 4 As shown, a heat-insulating wire insulation shield adopts a double-layer shielding structure and consists of two parts: a heat insulation layer 1 and an insulation layer 6 . The heat-insulating layer is made of heat-resistant resin, and mainly includes heat-insulating layer 1, anti-slip mat 2, heat-resistant connecting block 3, lifting hole 4 and other components. Anti-skid pads 2 are provided on the left and right sides of the inside of the shield to prevent the shield from sliding arbitrarily after it is installed. There is a lifting hole on the outside of the shielding cover, which is used for dismantling the insulating operating rod for live work. The heat-resistant connecting block 3 is used as the connection between the heat insulating layer 1 and the insulating layer 6 . The insulating layer 6 is processed by insulating resin, and mainly includes the insulating layer 6, the lifting hole, the slide rail 7, the insulating extension l...

Embodiment 2

[0024] A heat-insulating wire insulation shielding cover, the shielding cover adopts a double-layer shielding structure, the inner layer is a heat insulating layer 1, and the outer layer is an insulating layer 6; the inner layer and the outer layer are connected by a connecting block 3; the connecting block is an Heat-resistant and flame-retardant connection block; both ends of the shielding cover are provided with installation chute, and the chute is connected with other shielding covers; lifting holes 4 are set on the insulating layer and the heat insulating layer, and the hole diameter of the lifting hole is the same as the diameter of the insulating operating rod. Compatible; the heat insulation layer is made of heat insulation and flame retardant material, which is a hollow cylinder structure, and the wire entry is set under the heat insulation layer; the anti-skid pad 2 is set on the inside of the heat insulation layer; The upper end of the insulating layer is provided wi...

Embodiment 3

[0028] A heat-insulating wire insulation shielding cover, which differs from Embodiments 1 and 2 in that, on the basis of the surface of the insulating layer in Embodiment 1 or the surface of the waterproof layer in Embodiment 2, a coating layer can be provided on the outermost surface, The ready-to-use coating material evenly covers the outer surface. The coating material mainly includes polypropylene coating material, which can effectively improve the fullness, gloss, wear resistance and aging resistance of the outer surface of the mask, making it smooth and beautiful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com