Array substrate and touch-control display device and testing method thereof

A technology for array substrates and test pads, applied in the fields of array substrates and touch display devices, can solve problems such as difficulty in detecting the potential of common electrodes, short circuit between pixel electrodes and common electrodes, and influence on measurement results, so as to improve accuracy and reduce difficulty , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

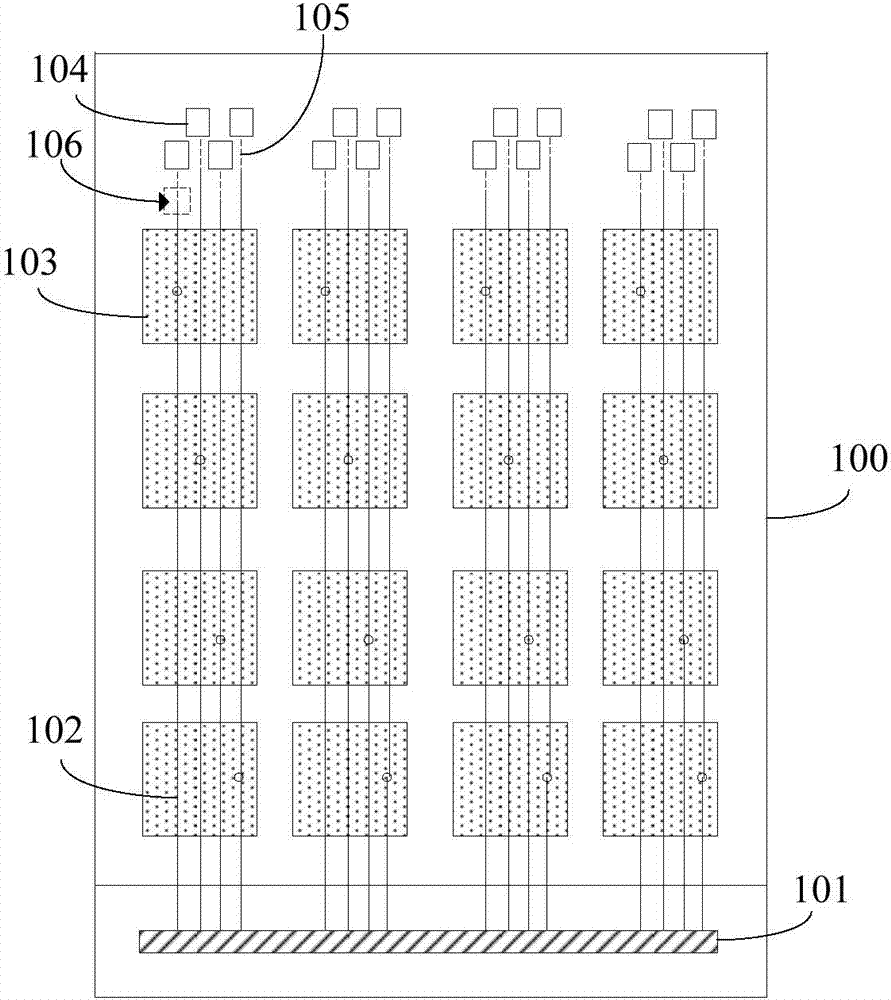

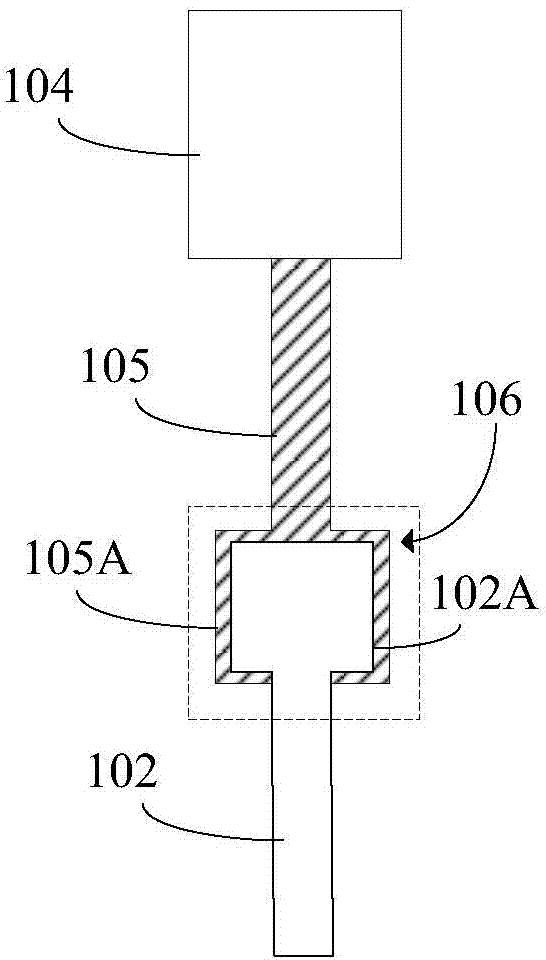

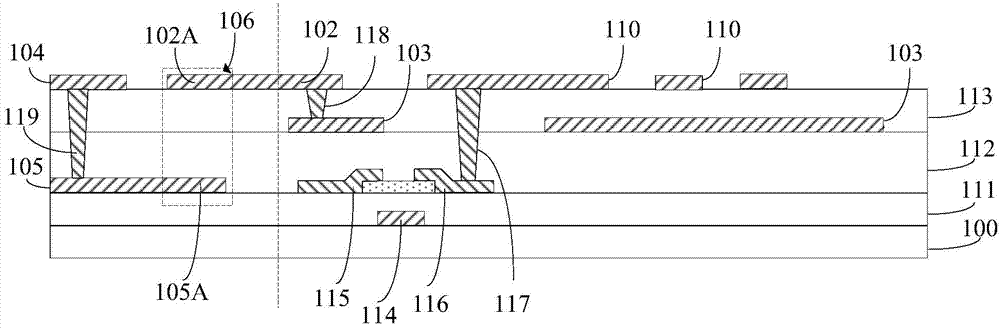

[0031] As mentioned in the background, in the prior art touch display device, the common electrodes in the pixel area are multiplexed as touch electrodes, which can reduce the size of the touch display device. Due to the limitation of the film layer structure, the common electrode multiplexed as the touch electrode is under the insulating layer, which makes it very difficult to detect the potential of the common electrode during the analysis process. Oscilloscope probes and flat panel display manual detection equipment probes are not easy to pierce the insulation layer, especially when the pixel electrode is above the common electrode, it is easy to make the probe touch the pixel electrode when piercing the probe. If you use violence If it is pierced, it is easy to short-circuit the pixel electrode and the common electrode, which will affect the measurement result.

[0032] In addition, if the common electrode is directly connected to the test terminal provided on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com