A performance test device and test method of a partial discharge ultra-high frequency sensor

A UHF sensor, partial discharge technology, applied in measurement devices, instruments, measurement of electrical variables, etc., can solve the gap in the use of sensors, the difficulty of building and standardizing test platforms, and the inability to clearly and completely describe the time-domain behavior characteristics of UHF sensors. and other problems, to achieve the effect of simplifying the measurement system and accurate characterization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings.

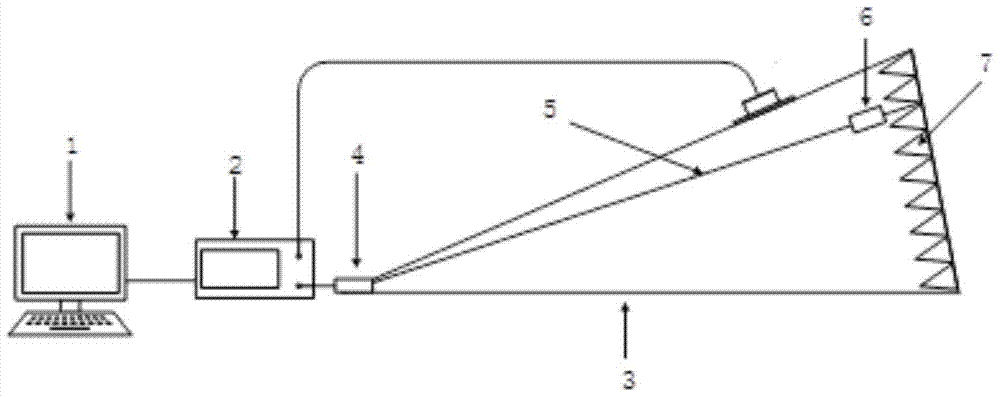

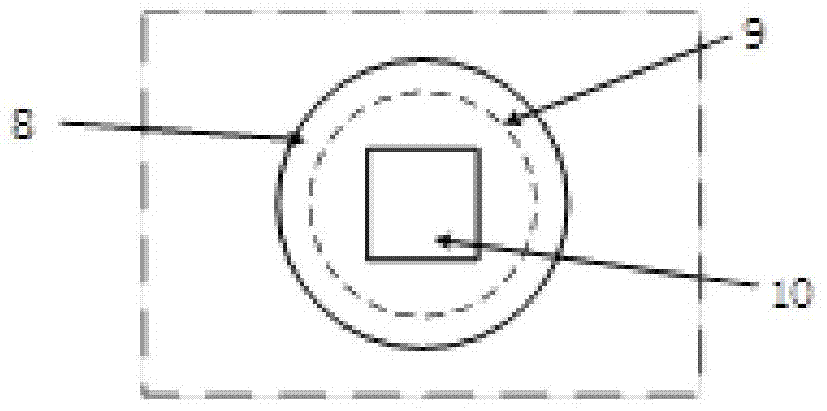

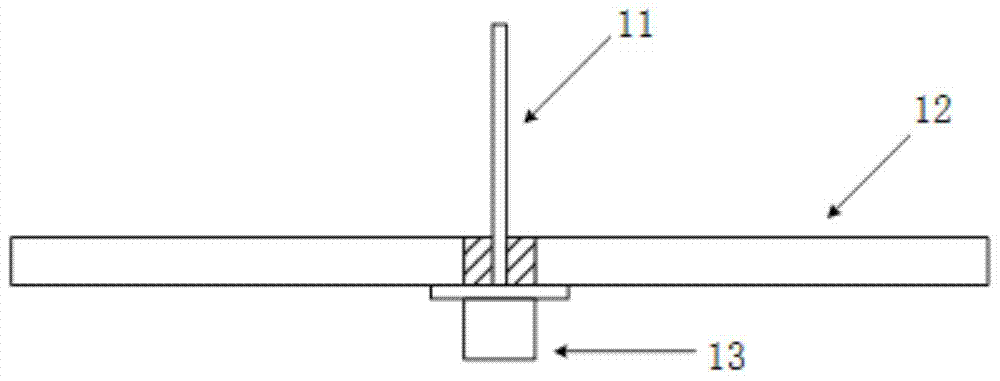

[0050] Such as figure 1 As shown, the test device includes a data processing computer 1, a vector network analyzer 2, a GTEM cell 3, a polytetrafluoroethylene cover plate 8 and a UHF sensor to be tested or a calibration antenna 10, wherein the signal input terminal of the GTEM cell 3 It is a coaxial feed head 4, the inner conductor of which extends to the bottom of the cone to form a triangular metal core plate 5, and the bottom of the cone is provided with a 50Ω resistance array 6 and microwave absorbing material 7 for impedance matching, and a circular Hole 9.

[0051] When in use, connect port 1 of the vector network analyzer 2 to the coaxial feed head 4, and port 2 to receive the UHF sensor or calibration antenna 10, and place it on the circular opening 9 through the polytetrafluoroethylene cover plate 8.

[0052] The function of vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com