Performance testing device and testing method for partial discharge ultra-high frequency sensor

A UHF sensor, partial discharge technology, applied in measurement devices, instruments, measuring electrical variables, etc., can solve the problem of inability to clearly and completely describe the time-domain behavior characteristics of UHF sensors, the gap in sensor use effects, and the difficulty of test platform construction and standardization And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings.

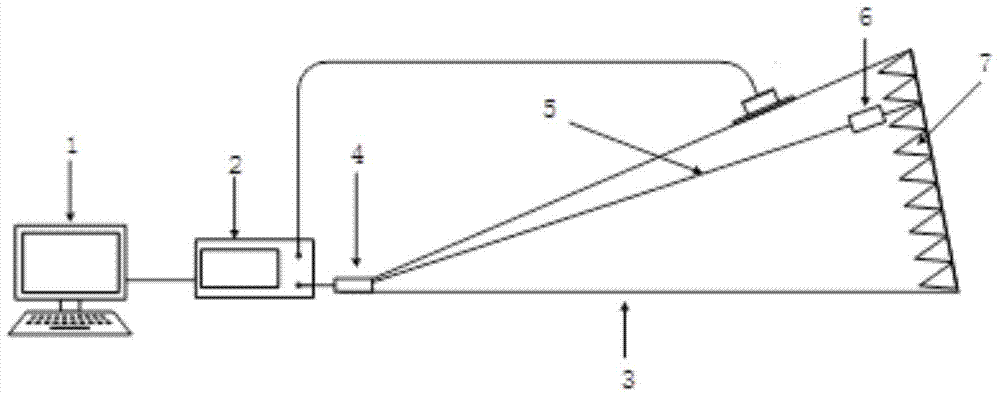

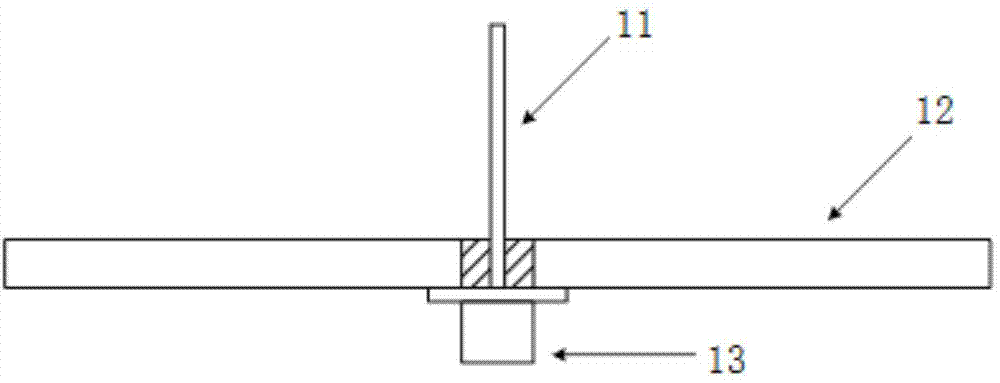

[0050] Such as figure 1 As shown, the test device includes a data processing computer 1, a vector network analyzer 2, a GTEM cell 3, a polytetrafluoroethylene cover plate 8 and a UHF sensor to be tested or a calibration antenna 10, wherein the signal input terminal of the GTEM cell 3 It is a coaxial feed head 4, the inner conductor of which extends to the bottom of the cone to form a triangular metal core plate 5, and the bottom of the cone is provided with a 50Ω resistance array 6 and microwave absorbing material 7 for impedance matching, and a circular Hole 9.

[0051] When in use, connect port 1 of the vector network analyzer 2 to the coaxial feed head 4, and port 2 to receive the UHF sensor or calibration antenna 10, and place it on the circular opening 9 through the polytetrafluoroethylene cover plate 8.

[0052] The function of vector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com