Ultrasonic measurement instrument for pile bottom sediment thickness

A sediment thickness and ultrasonic technology, applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems of lack of authenticity and reliability, and large human errors in detection results, so as to maintain balance, ensure fluidity, and measure value-accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

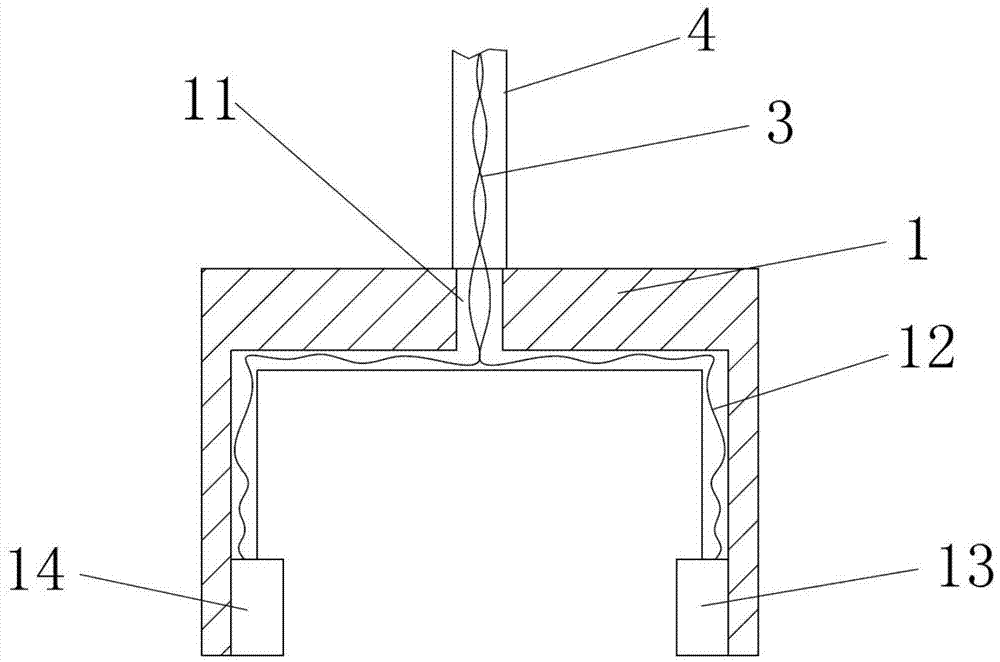

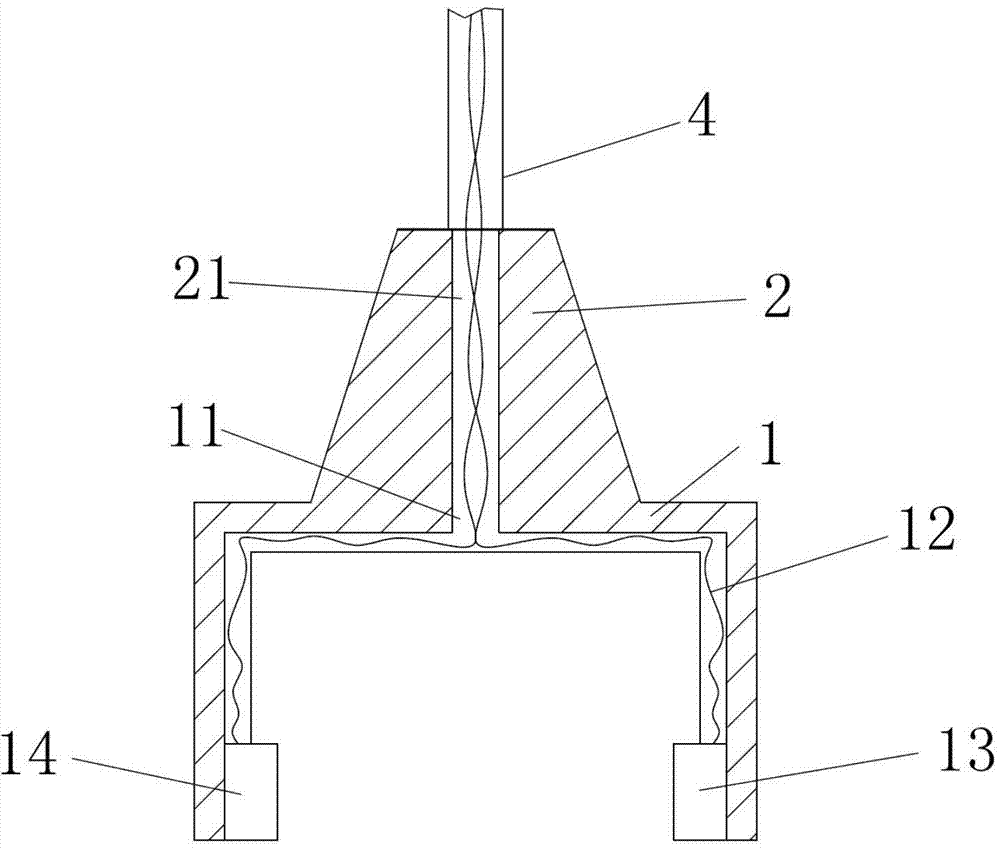

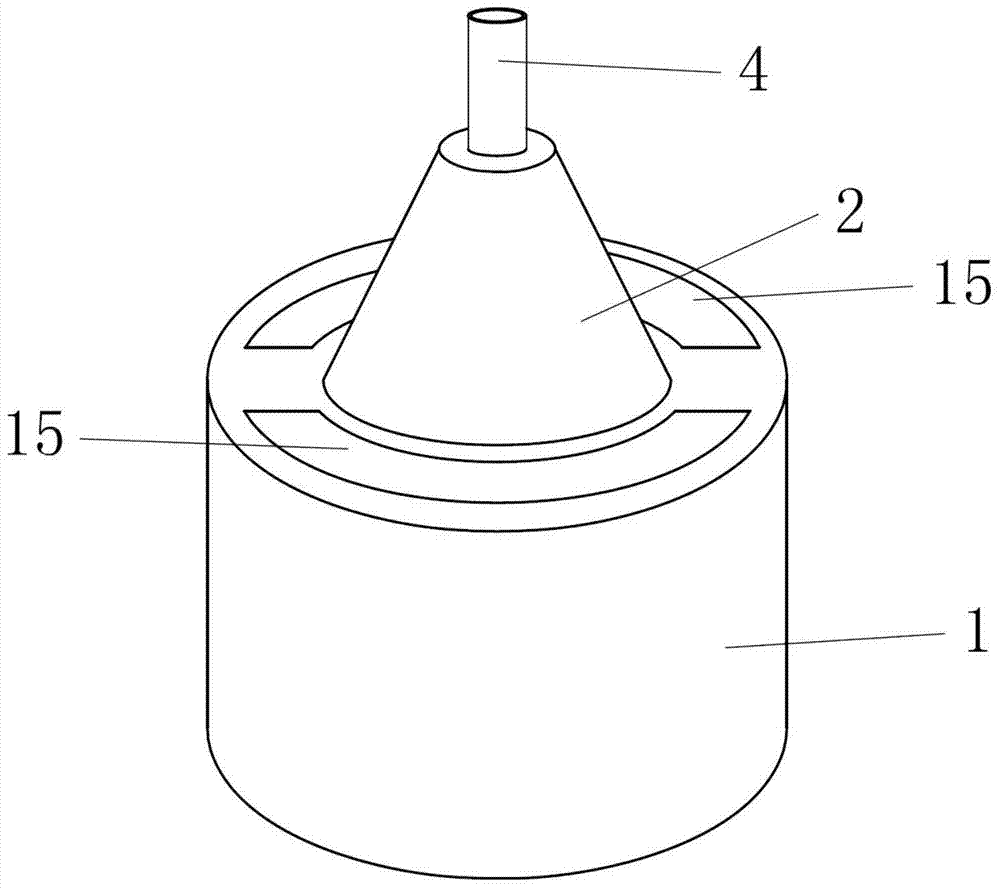

[0027] For a schematic cross-sectional structure diagram of Embodiment 1 of the measuring hammer of the present invention, see figure 1 , including a hammer body 1, the hammer body 1 is an inverted cylindrical structure with a bottom, a hammer body through hole 11 is provided at the bottom center of the hammer body 1, and the hammer body through hole 11 is used for the passage of the ultrasonic probe line 3, and the ultrasonic probe line 3 and enter the measuring rope 4; on the bottom of the hammer body 1, there are two symmetrical crescent-shaped mud discharge holes 15 that pass through the inside and outside of the hammer body 1. The ultrasonic transmitting device 13 and the ultrasonic receiving device 14 are provided, and the ultrasonic transmitting device 13 and the ultrasonic receiving device 14 are centrally symmetrical with the axis of the hammer body 1; above the ultrasonic transmitting device 13 and the ultrasonic receiving device 14, the cylindrical shape of the hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com