Piston reciprocating-type single-cylinder high-speed internal combustion engine

A reciprocating and engine technology, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of reducing the value of engines, increasing engine manufacturing costs, and short engine strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

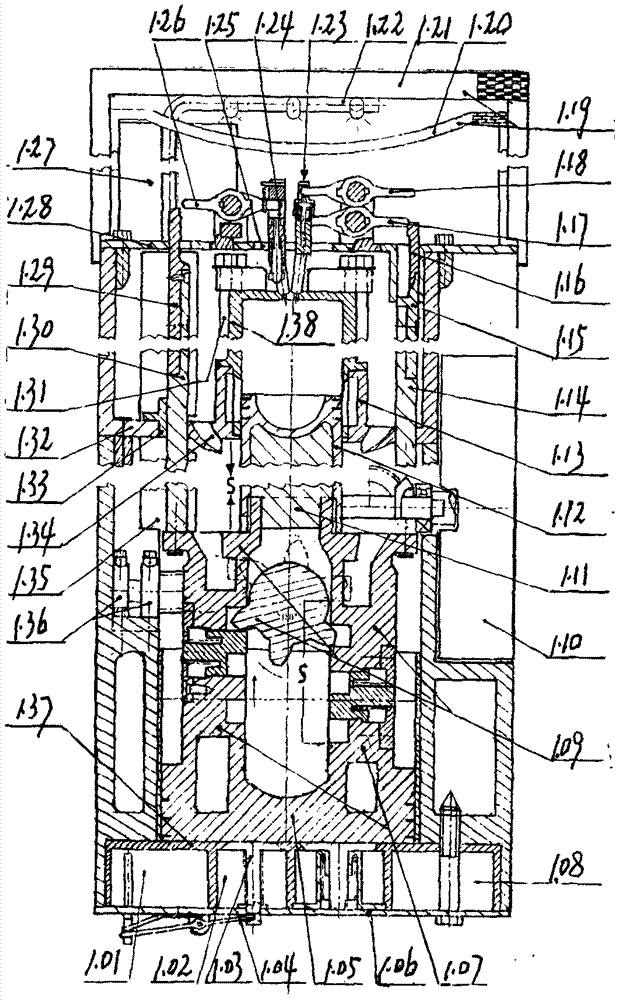

[0107] Embodiment 1: A piston reciprocating high-speed single-cylinder diesel engine

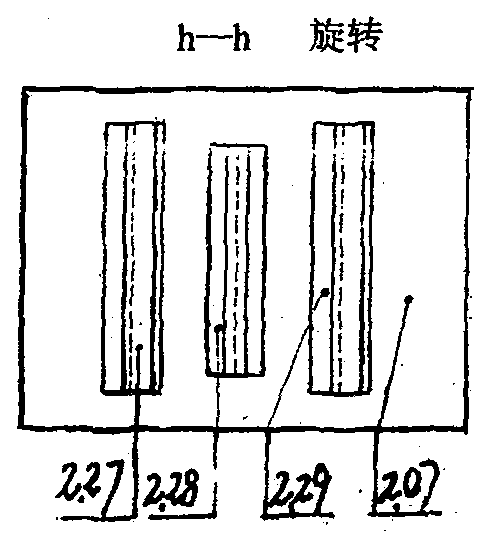

[0108] Power system: use the rack and pinion mechanism described in the third implementation of the invention patent "ZL200710147446.7" (such as Figure 2.03 Shown, hereinafter referred to as "the third kind of rack and pinion mechanism") is used as the power mechanism of the engine. Figure 1.01 Shown, this power mechanism [1.09] is arranged on the middle of the lower part body that engine is divided into upper and lower two parts with a diaphragm [1.32].

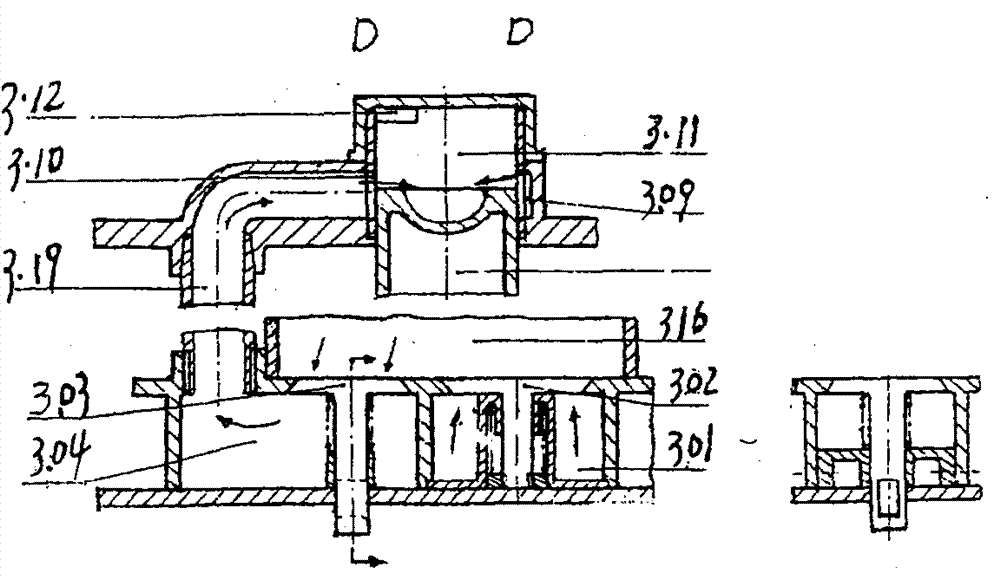

[0109] Supercharging system: the supercharging mechanism and its system described in the first implementation of the invention patent "ZL200710193938.X" ( Figure 3.01-3.05 Shown) remove the pressurized air bypass system, and the remaining parts are made according to the description and accompanying drawings, and are used as the supercharging mechanism and system of the engine. Figure 1.01 Shown: the upper end surface of the power mec...

specific Embodiment approach 2

[0127] Embodiment 2: A piston reciprocating single-cylinder gasoline engine, Figure 1.04 and Figure 9.03 It is shown that the engine cylinder cooperates with the engine cylinder seat formed by the gas storage channel on the compressed air, which can form a strong eddy current air supply; the secondary fuel pump injection system ( Figure 4.10 In the first fuel injection shown), a leaner mixture is pre-formed, which is suitable for a high compression ratio; during the second fuel injection, the leaner mixture is compressed and denser, and the injected gasoline mist is ignited A high-concentration mixture that is easy to ignite is formed at the place, which is easy to ignite and burn. The above air supply conditions and the secondary fuel injection cooperate to form two stratified mixtures of different concentrations in the engine cylinder, thereby overcoming the inability to use gasoline in the primary fuel pump injection of the single-cylinder diesel engine described in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com