Beam pumping unit

A beam pumping unit and beam beam technology are applied in wellbore/well components, production fluid, earthwork drilling and production, etc., which can solve problems such as the inability to automatically adjust the position of the center of gravity of the balance block at any time, difficulty in smooth flow of lubricating oil, and oil pumping. The machine can not work normally and other problems, to achieve the effect of small balance torque, fast heating speed, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

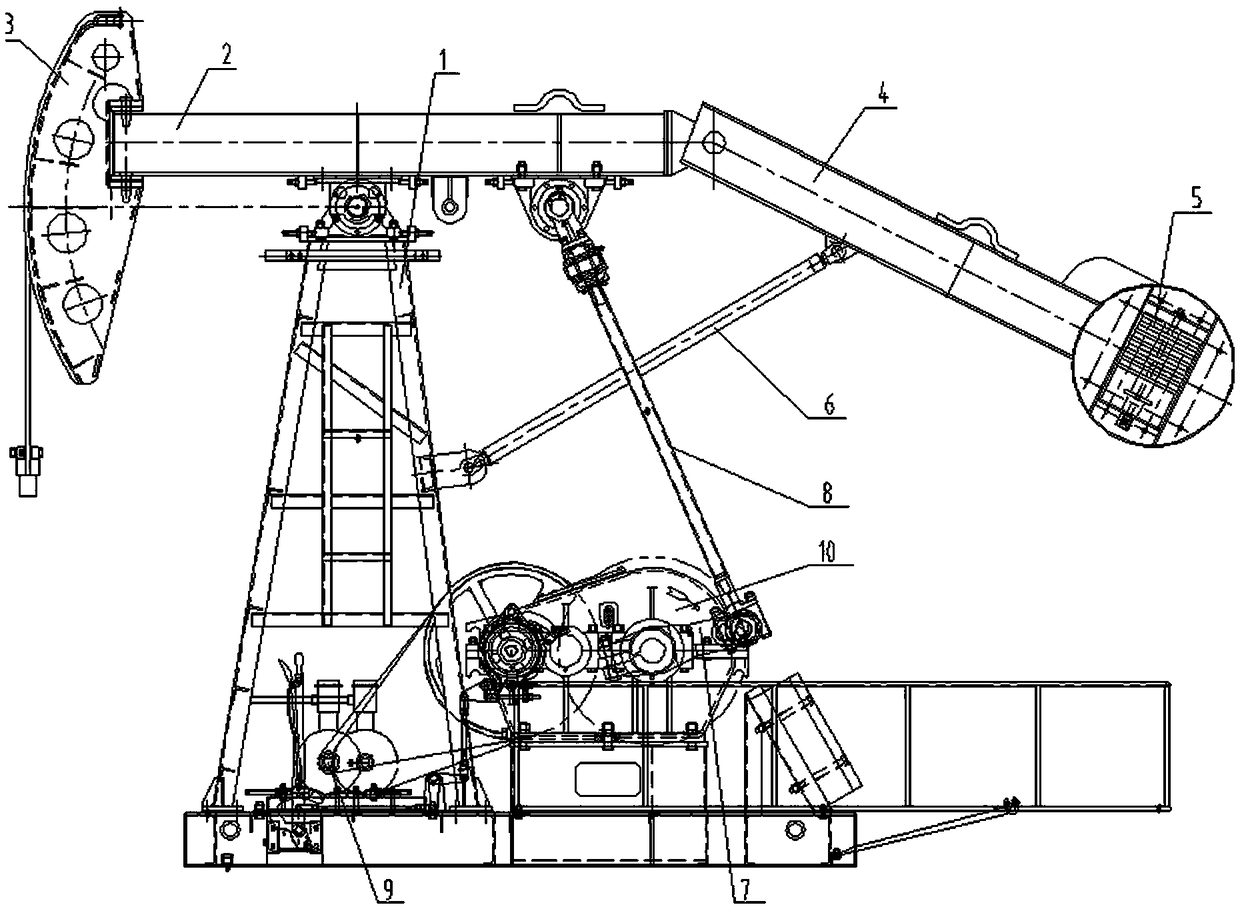

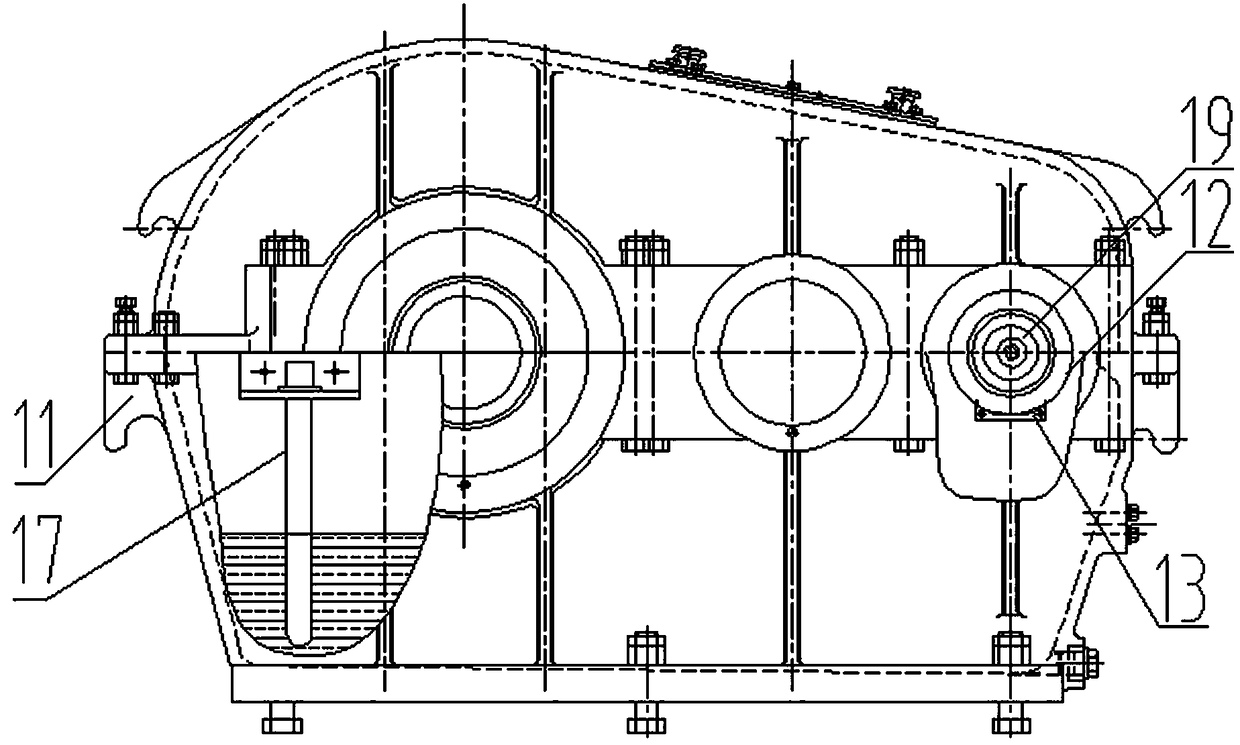

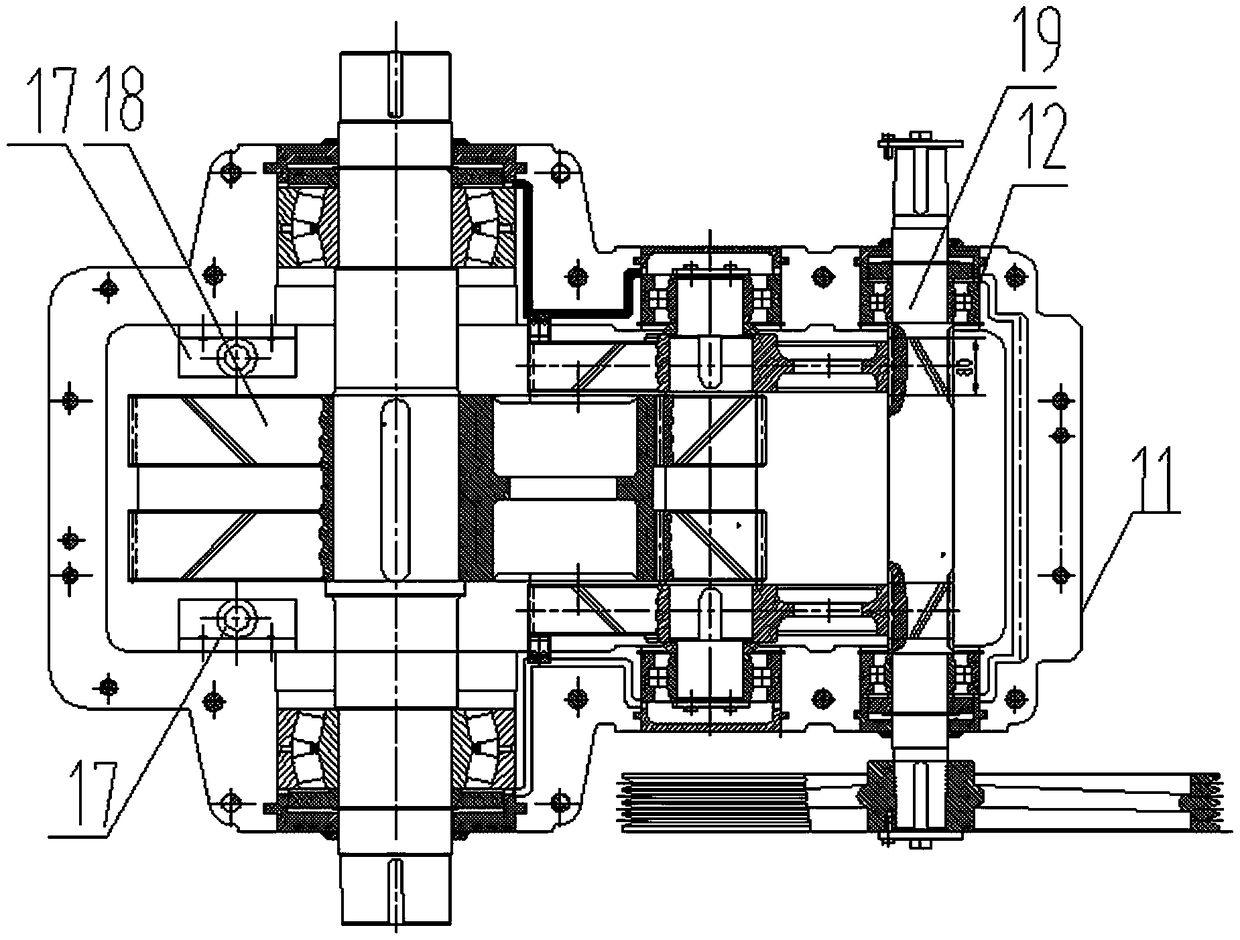

[0031]A beam pumping unit, comprising a bracket 1, a motor 9, a reducer 10, a crank 7, a connecting rod 8, a beam 2, a donkey head 3, a constant temperature heater 17, a balance arm 4, a balance weight 5 and a support rod 6. The traveling beam 2 is movably connected to the bracket 1, the donkey head 3 is fixed on one end of the traveling beam 2, the balance arm 4 is movably connected to the other end of the traveling beam 2, and the balance weight 5 is fixed on the balance On the arm 4, one end of the support rod 6 is movably connected to the bracket 1, and the other end is movably connected to the balance arm 4, and the beam 2 cooperates with the support rod 6 to drive the balance weight 5 to swing; the motor 9 and the reducer 10 connected, the reducer 10 is connected with the crank 7 to drive the crank 7 to rotate, the connecting rod 8 is movably connected between the crank 7 and the beam 2, the crank 7 drives the beam 2 to swing through the connecting rod 8, and the constant...

Embodiment 2

[0036] A beam pumping unit, comprising a bracket 1, a motor 9, a reducer 10, a crank 7, a connecting rod 8, a beam 2, a donkey head 3, a constant temperature heater 17, a balance arm 4, a balance weight 5 and a support rod 6. The traveling beam 2 is movably connected to the bracket 1, the donkey head 3 is fixed on one end of the traveling beam 2, the balance arm 4 is movably connected to the other end of the traveling beam 2, and the balance weight 5 is fixed on the balance On the arm 4, one end of the support rod 6 is movably connected to the bracket 1, and the other end is movably connected to the balance arm 4, and the beam 2 cooperates with the support rod 6 to drive the balance weight 5 to swing; the motor 9 and the reducer 10 connected, the reducer 10 is connected with the crank 7 to drive the crank 7 to rotate, the connecting rod 8 is movably connected between the crank 7 and the beam 2, the crank 7 drives the beam 2 to swing through the connecting rod 8, and the constan...

Embodiment 3

[0039] A beam pumping unit, comprising a bracket 1, a motor 9, a reducer 10, a crank 7, a connecting rod 8, a beam 2, a donkey head 3, a constant temperature heater 17, a balance arm 4, a balance weight 5 and a support rod 6. The traveling beam 2 is movably connected to the bracket 1, the donkey head 3 is fixed on one end of the traveling beam 2, the balance arm 4 is movably connected to the other end of the traveling beam 2, and the balance weight 5 is fixed on the balance On the arm 4, one end of the support rod 6 is movably connected to the bracket 1, and the other end is movably connected to the balance arm 4, and the beam 2 cooperates with the support rod 6 to drive the balance weight 5 to swing; the motor 9 and the reducer 10 connected, the reducer 10 is connected with the crank 7 to drive the crank 7 to rotate, the connecting rod 8 is movably connected between the crank 7 and the beam 2, the crank 7 drives the beam 2 to swing through the connecting rod 8, and the constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com