Preparation method of thiosemicarbazide imidazoline derivative corrosion inhibitor

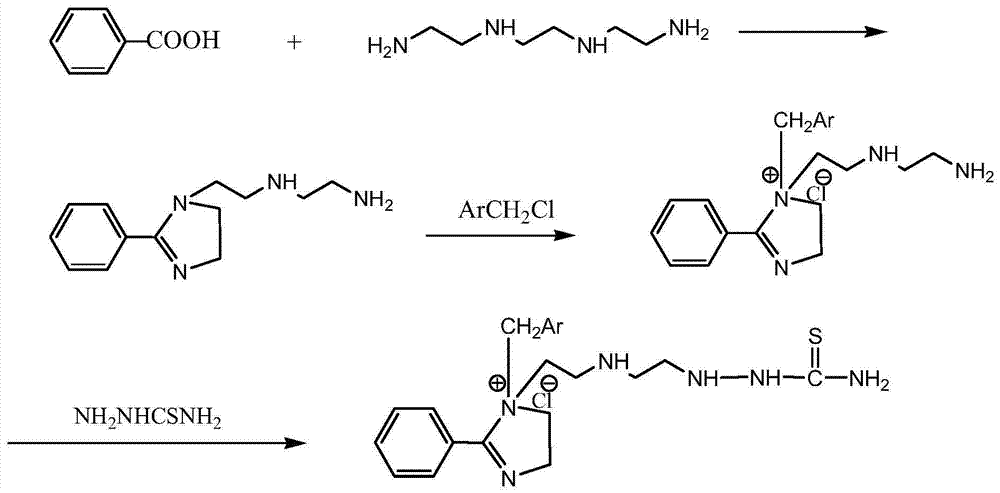

A thiosemicarbazide-based imidazoline and derivative technology is applied in the field of preparation of a thiosemicarbazide-based imidazoline derivative corrosion inhibitor, and can solve the problems of low corrosion inhibition efficiency, high cost, low slow release efficiency and the like, Achieve the effect of improving economic benefits, inhibiting corrosion and increasing corrosion inhibition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0021] A preparation method of a thiosemicarbazide based imidazoline derivative corrosion inhibitor, comprising the steps of:

[0022] (1) Dissolve 0.05mol (6.1g) of benzoic acid and 9.6mL of water-carrying agent xylene at a volume ratio of 1:2 (the volume of benzoic acid is calculated by the relative density of benzoic acid), and heat up to 100°C , start to drop triethylenetetramine 0.1mol (14.6g) in the bottle, the dripping of triethylenetetramine adopts the constant pressure dropping funnel to carry out dropwise addition, and the dripping speed is controlled at 10s / drop, wait for triethylenetetramine to drip After the addition was completed, the temperature was raised to 150°C for reflux reaction for 2.0 hours to obtain the amidation product; the temperature was then raised to 220°C for ring formation reaction, and the reaction was stopped when no more water was generated. The reaction time was 2.0 hours, and the reaction time was reduced Xylene was evaporated to obtain 9....

preparation Embodiment 2

[0026] A preparation method of a thiosemicarbazide based imidazoline derivative corrosion inhibitor, comprising the steps of:

[0027] (1) Dissolve 0.05mol (6.1g) of benzoic acid and 9.6mL of water-carrying agent xylene at a volume ratio of 1:2 (the volume of benzoic acid is calculated by the relative density of benzoic acid), and heat up to 105°C , start to drop triethylenetetramine 0.05mol (7.3g) in the bottle, the dripping of triethylenetetramine adopts the constant pressure dropping funnel to carry out dropwise addition, and the dripping speed is controlled at 8s / drop, wait for triethylenetetramine to drip After the addition was completed, the temperature was raised to 140°C for reflux reaction for 2.2 hours to obtain the amidation product; the temperature was then raised to 230°C for ring formation reaction, and the reaction was stopped when no more water was generated. The reaction time was 2.2 hours, and the reaction was reduced Xylene was evaporated to obtain 8.47 g o...

preparation Embodiment 3

[0031] A preparation method of a thiosemicarbazide based imidazoline derivative corrosion inhibitor, comprising the steps of:

[0032] (1) Dissolve 0.1mol (12.2g) of benzoic acid and 21.2mL of water-carrying agent xylene at a volume ratio of 1:2 (the volume of benzoic acid is calculated by the relative density of benzoic acid), and heat up to 95°C , start to drop triethylenetetramine 0.1mol (7.3g) in the bottle, the dripping of triethylenetetramine adopts the constant pressure dropping funnel to carry out dropwise addition, and the dripping speed is controlled at 12s / drop, wait for triethylenetetramine to drip After the addition was completed, the temperature was raised to 160°C for reflux reaction for 1.8 hours to obtain the amidation product; the temperature was then raised to 250°C for ring formation reaction, and the reaction was stopped when no more water was generated. Xylene was evaporated to obtain 16.24 g of cyclized imidazoline intermediate, with a yield of 70%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com