Blast furnace iron mouth dedusting cover

A technology of dust removal cover and iron mouth, which is applied in the direction of dust collector, etc., can solve the problems of high dust collection area, the inability to lower the dust removal cover, increase the dust removal effect of the dust removal cover, etc., and achieve the effect of uniform flow of smoke and dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

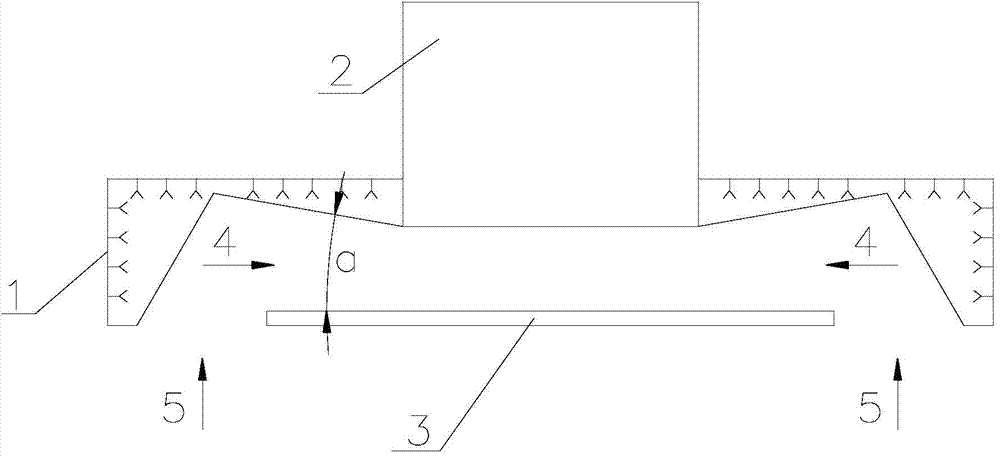

[0011] In order to better understand the purpose, structure and function of the present invention, a blast furnace iron hole dust removal hood of the present invention will be described in further detail below with reference to the accompanying drawings.

[0012] like figure 1 As shown, the blast furnace iron mouth dust removal hood of the present invention comprises a dust collecting hood body 1, a suction port 2 is formed on the top wall of the dust collecting hood body 1, a smoke guide plate 3 is horizontally arranged under the top wall, and the smoke guide plate 3 is connected with The air inlet 2 is set directly opposite. Wherein, the smoke guide plate 3 can be fixed on the dust collecting hood 1 by means of bolts or welding, and the smoke guide plate 3 can be flat or curved. Set to flat. In addition, in order to adapt to the high temperature smoke and dust sucked by the iron mouth, the inside of the dust collecting cover 1 and the smoke guide plate 3 can be provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com