Preparation of two kinds of carbon quantum dots with different luminescent properties by "one pot" method

A technology of carbon quantum dots and properties, applied in the field of preparation of carbon-based nanomaterials, can solve problems such as complex synthesis process and difficult synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

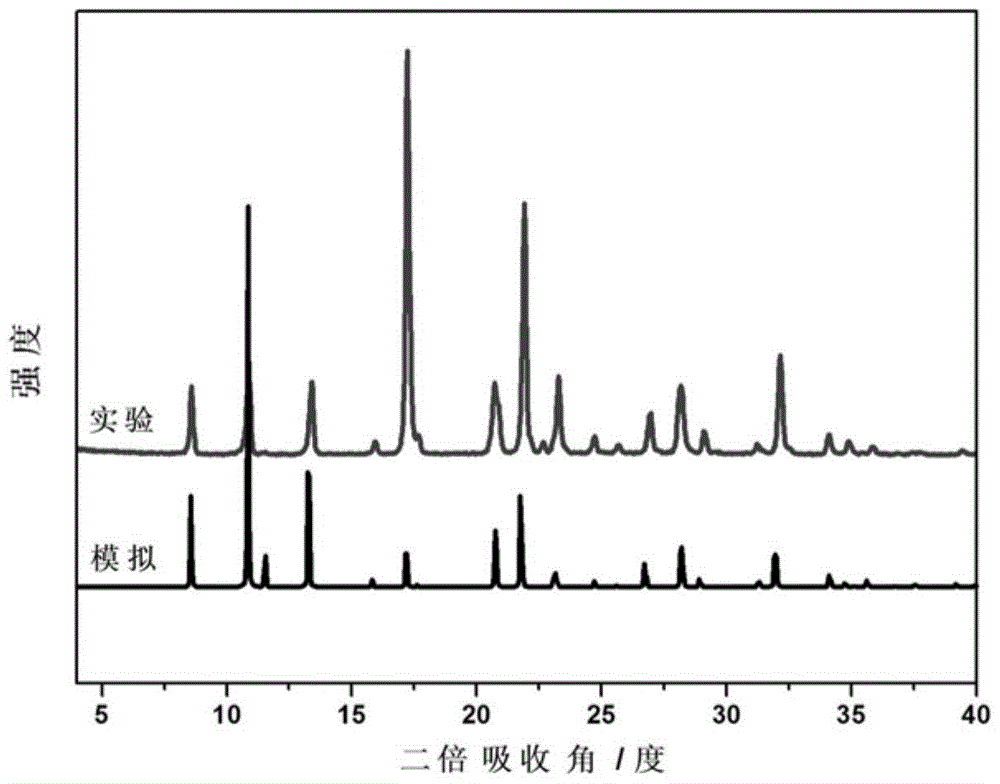

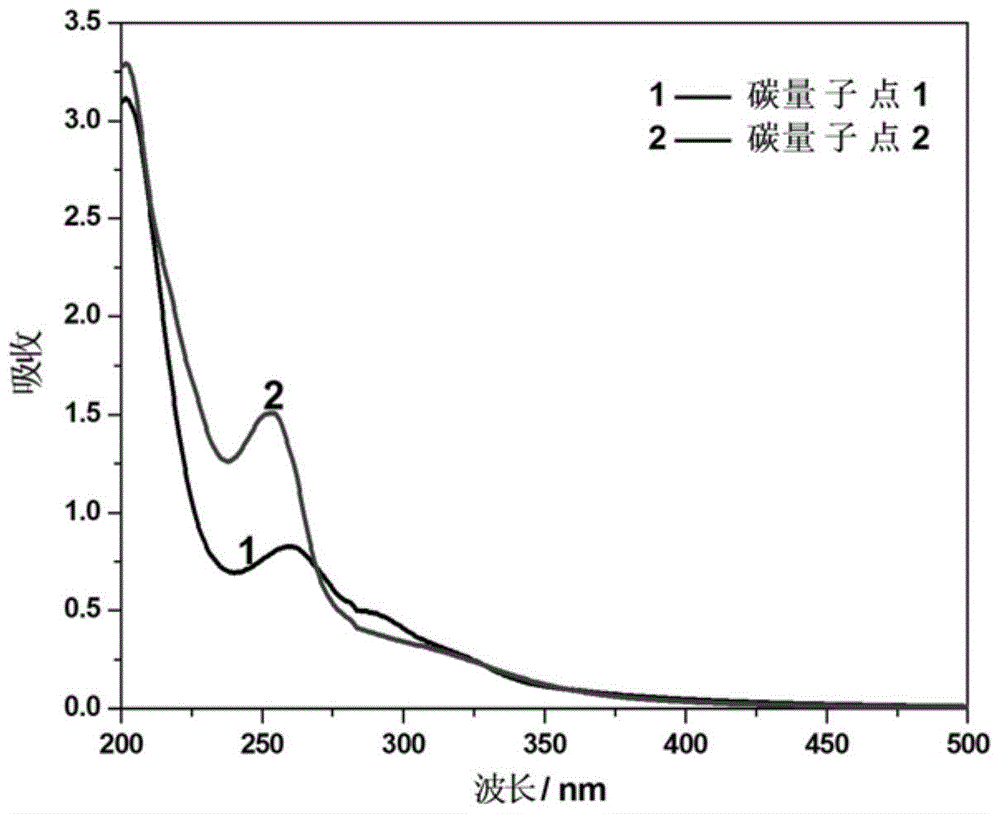

[0036] With the help of the hydrothermal synthesis and post-treatment of LEV-type magnesium-doped aluminum phosphate molecular sieve, two different fluorescent carbon dots were prepared by the "one-pot" method.

[0037] Dissolve 0.187g pseudo-boehmite in 7mL water, continue to add 0.164g magnesium acetate, 0.35mL phosphoric acid and 0.4mL azamethylpiperidine under magnetic stirring, and continue stirring for 1 hour. Transfer the obtained gel into a stainless steel reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in an oven at 180°C, and heat and react for 3 days under the pressure naturally generated by the reaction kettle;

[0038] After the reaction is completed, the reaction kettle is taken out and placed at room temperature for natural cooling; the brown-yellow supernatant in the kettle is recovered (to obtain soluble carbon quantum dots CND-1). Purification of carbon quantum dots CND-1: Filter out insoluble substances with a 0.22 micron filter, and...

Embodiment 2

[0043] With the help of the hydrothermal synthesis and post-treatment of AFI-type aluminum phosphate molecular sieve, two different fluorescent carbon dots were prepared by the "one-pot" method.

[0044] Dissolve 0.575 g phosphoric acid in 7 mL water, add 0.42 g boehmite CATAPAL B and 0.56 mL triethylamine under magnetic stirring, and continue stirring for 1 hour. Transfer the obtained gel into a stainless steel reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in an oven at 200°C, and heat and react for 1 day under the autogenous pressure of the reaction kettle;

[0045] After the reaction is completed, the reaction kettle is taken out and placed at room temperature for natural cooling; the milky white supernatant in the kettle is recovered (to obtain soluble carbon quantum dot CND-1). Purification of carbon quantum dots CND-1: filter out the insoluble matter with a 0.22 micron filter, and dialyze the filtrate with a dialysis bag with a molecular weight...

Embodiment 3

[0050] With the help of the hydrothermal synthesis and post-treatment of CHA-type silicon-doped aluminum phosphate molecular sieve, two different fluorescent carbon dots were prepared by the "one-pot" method.

[0051] Disperse 1.02g of ground aluminum isopropoxide in 2.1g of tetraethylammonium hydroxide aqueous solution, magnetically stir until it is completely dissolved, add 0.69g of phosphoric acid dropwise, continue stirring for 2 hours, and then slowly add 0.25g of silica sol, continue Stir for 1 hour. Transfer the obtained gel into a stainless steel reaction kettle lined with polytetrafluoroethylene, place the reaction kettle in a 170°C oven, and heat the reaction kettle for 5 days under autogenous pressure;

[0052] After the reaction is completed, the reaction kettle is taken out and placed at room temperature for natural cooling; the supernatant in the kettle is recovered (to obtain soluble carbon quantum dots CND-1). Purification of carbon quantum dots CND-1: filter out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com