Biogas slurry recovery system and method for preparing liquid compound fertilizer using the system

A recycling system and compound fertilizer technology, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of affecting the effect of complexation, unable to meet the problems of factory production and operation, and blocking with chemicals, so as to improve the utilization rate of fertilizers. , Conducive to absorption and utilization, the effect of promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

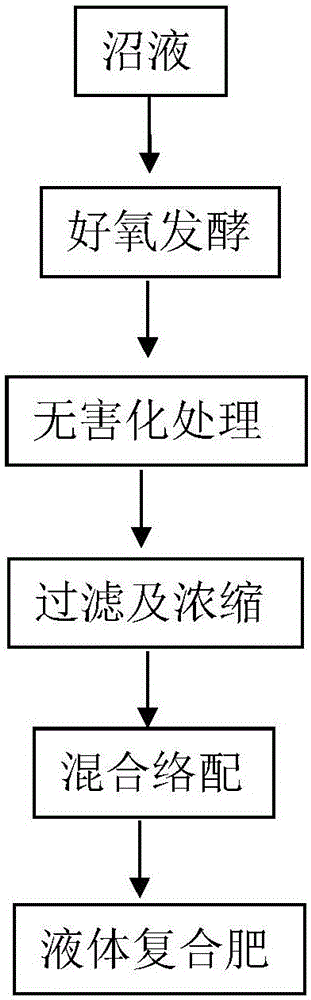

[0077] First, let the biogas slurry enter the aerobic fermentation tank, aerate intermittently, and carry out aerobic reaction for 4 hours to kill some bacteria and insect eggs in the biogas slurry. After the fully reacted biogas slurry, stop aeration and go through a stable sedimentation process for 1 hour.

[0078] The suspension obtained from the stable precipitation is introduced into the primary filter unit, where a filter is used for filtration, and the filtered biogas slurry can reach 40 mesh. The filtered biogas slurry enters the harmless treatment unit, and adopts the biofilm treatment method, which can adsorb a large amount of heavy metals quickly, remove unstable nitrogen and volatile phenols, organic acids and other substances harmful to crops, and meet the requirements of industrial large-scale production . The biogas slurry after harmless treatment enters the negative pressure concentration reactor. The vacuum degree in the reactor is kept at 90%, and the biogas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com