Flattening die-cutting mechanism for switching feeding mode by using floating guide roller

A technology of flattening and guide rollers, which is applied in the field of flattening and die-cutting mechanisms, can solve problems such as low production efficiency, long waiting time, and inability to better meet the requirements of high-speed die-cutting production, so as to improve production efficiency and save Staying waiting time, which is beneficial to the effect of long-term production of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

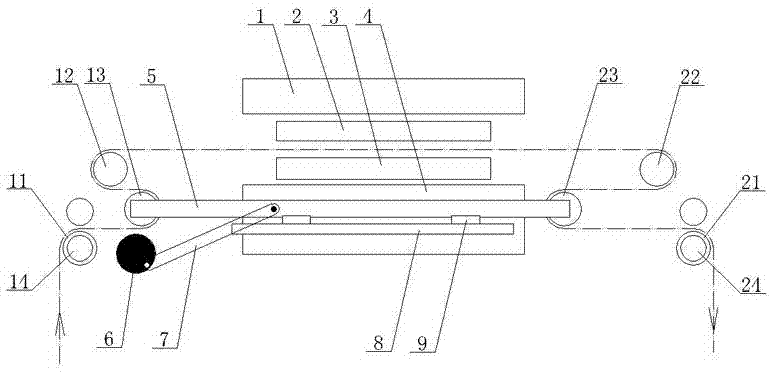

[0011] As shown in the figure, the flat die-cutting mechanism utilizing floating guide rollers to switch the feeding mode of the present invention includes an upper mold frame plate 1, a knife mold 2, a knife mold bottom plate 3 and a lower mold frame plate 4, and the knife mold 2 is opposite to the knife The mold bottom plate 3 moves up and down, and the paper feeding side of the knife mold bottom plate 3 is provided with a front fixed guide roller 12, a front floating guide roller 13 and a paper feed traction roller 11, and the paper feed traction roller 11 is driven by the first servo motor 14, so The paper feed traction roller 11, the front floating guide roller 13, and the front fixed guide roller 12 are set at different heights, the paper feed traction roller 11 is located at the bottom, the front floating guide roller 13 is located in the middle, and the front floating guide roller 13 is opposite to the paper feed traction roller. 11. The front fixed guide roller 12 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com