The quick-loading structure of the material tank of the paint spray gun

A paint spray gun and material tank technology, which is applied in the field of paint spray guns, can solve the problems of long disassembly and assembly time of material tanks and paint spray guns, poor arc internal thread strength, and difficult car manufacturing, so as to save disassembly time and prolong the overall Lifespan, guarantee the effect of normal painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

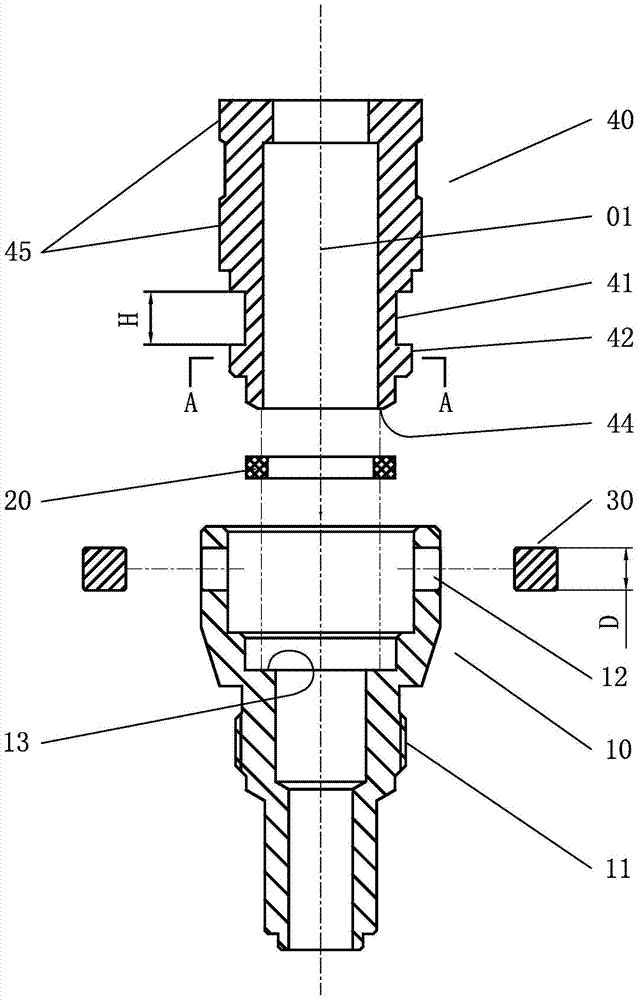

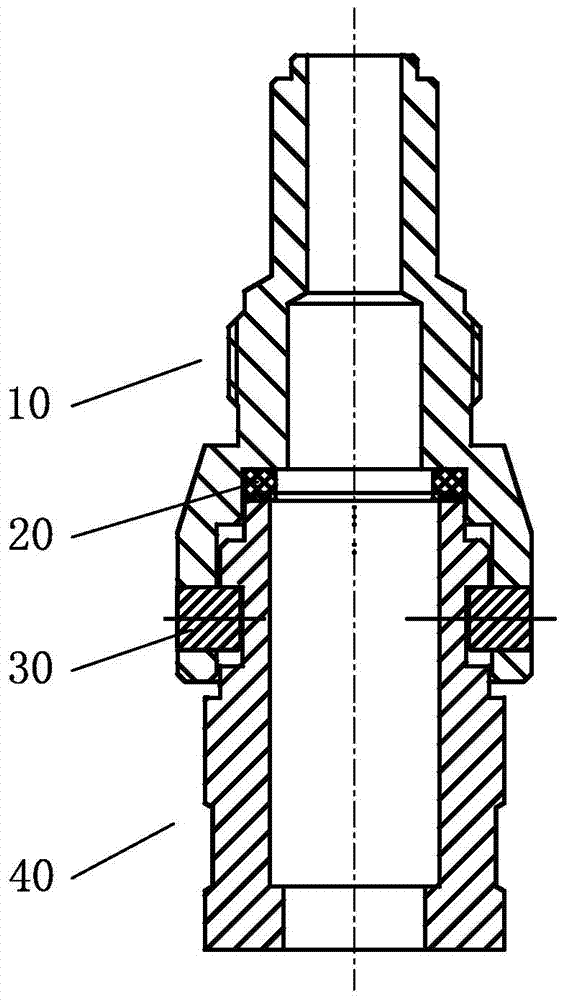

[0026] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 6 :

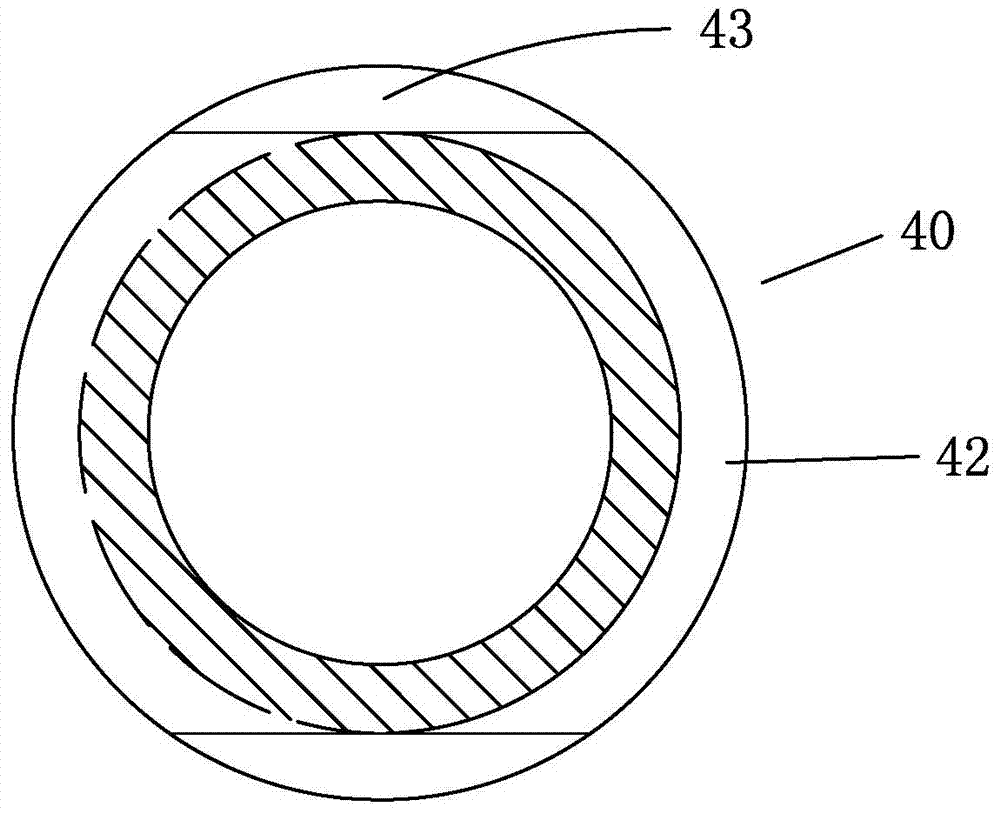

[0027] The quick-loading structure of the material tank of the paint spray gun, the upper inner wall of the joint one 10 is respectively provided with a short axis 30 or a protrusion transversely pointing to the axis 01 on both sides of the axis, and the lower outer wall 41 of the joint two 40 is axially symmetrical. Two sections of arc-shaped grooves 46 or protrusions 42 are provided, and the ends of the two sections of arc-shaped grooves 46 or protrusions 42 are provided with a gap 43 or a gap 43 or 47. The short shaft 30 or the protrusion on the joint one 10 moves axially through the gap 43 and then rotates to be clamped on the groove or the protrusion 42 on the joint two 40 to realize the quick connection of the joint one 10 and the joint two 40, A sealing ring 20 is provided between the first joint 10 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com