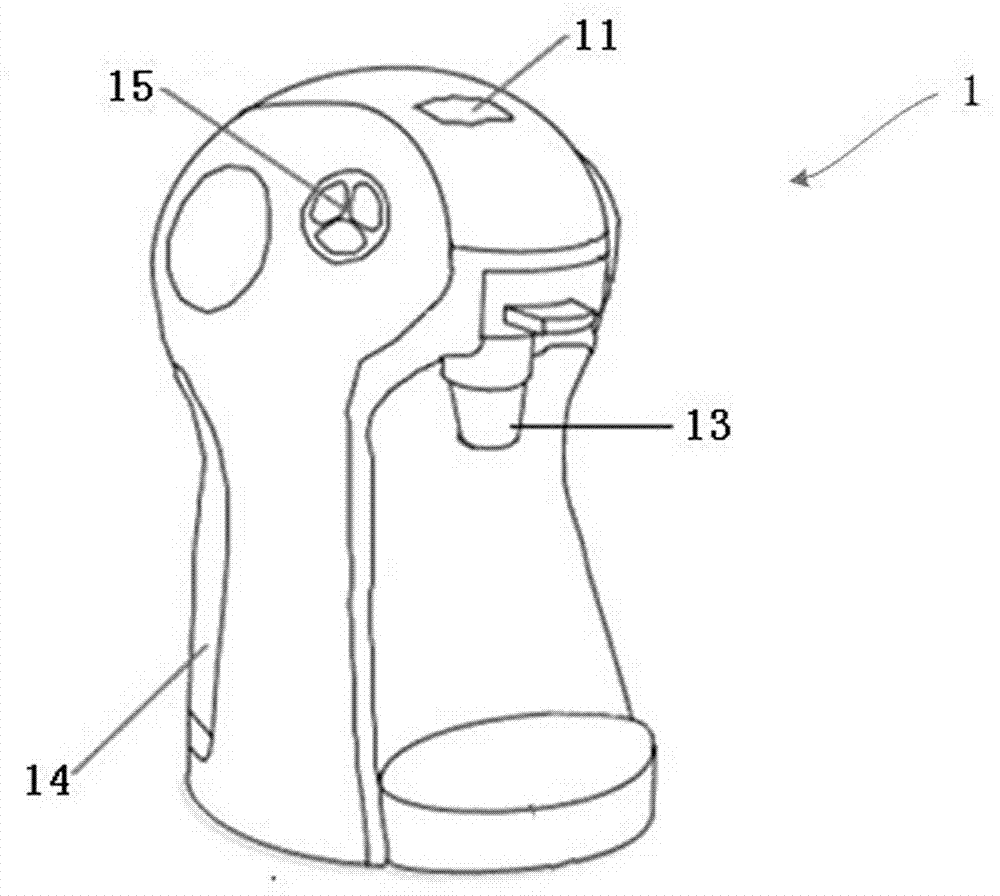

Capsule preparing machine with detection function, capsule and control method thereof

A technology of capsule brewing machine and control method, which is applied in home appliances, kitchen appliances, beverage preparation devices, etc., can solve problems such as cleaning failure, wrong brewing, and provide users with a healthy and hygienic coffee brewing environment, and achieve the degree of intelligence High, prevent the effect of brewing and cleaning operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

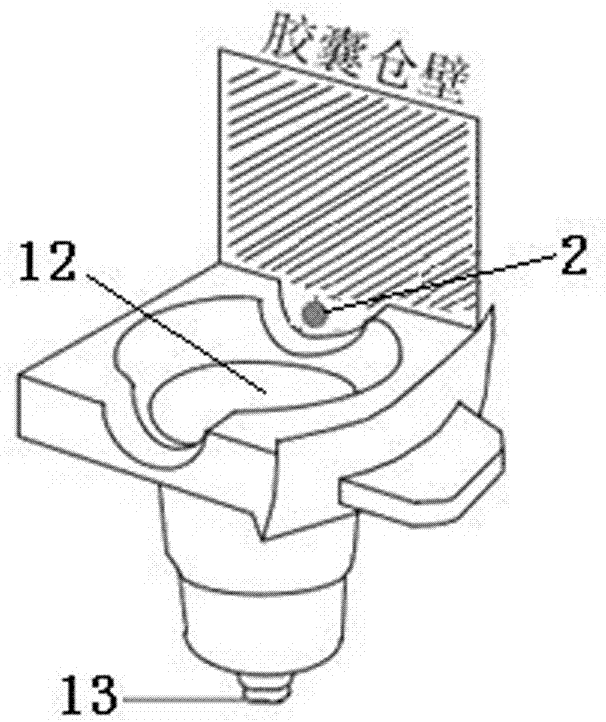

[0054] Image 6 It is a schematic structural diagram of the detection device 2 in this embodiment. Such as figure 2 As shown, the detection device 2 is installed on the wall of the capsule compartment, and includes a detection source 21 and an induction component 22 . After receiving the instruction to detect the capsule, the detection source 21 emits a beam of detection waves propagating in a straight line to the location of the capsule, and the detection waves can be ultrasonic waves, light waves, infrared rays, short waves or microwaves. When there is a capsule in the capsule chamber, the probe wave will be reflected. The sensing part 22 is installed at a position where reflected waves can be sensed. In this way, when there is a capsule in the capsule compartment, the wave emitted by the detection source 21 is reflected by the capsule and then detected by the sensing part 22; when there is no capsule in the capsule compartment, the wave emitted by the detection source 2...

Embodiment 2

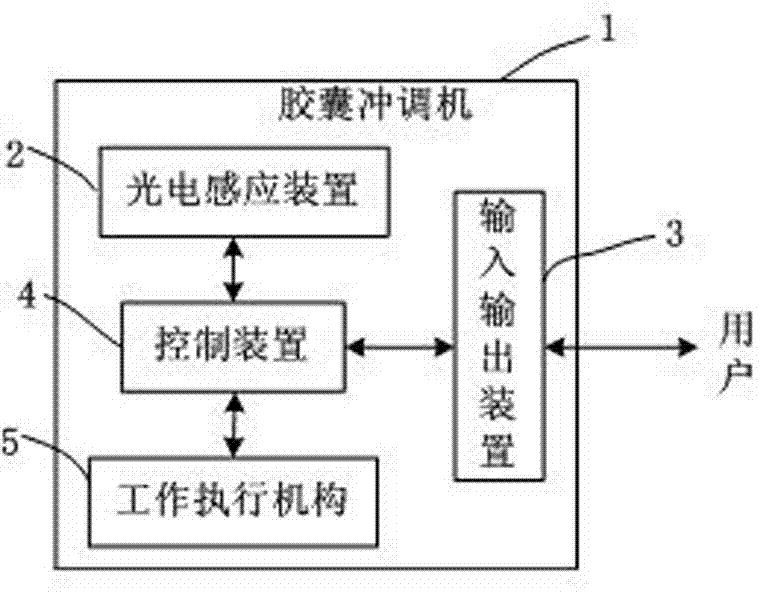

[0058] The capsule brewing machine 1 can use a variety of capsules, such as coffee capsules, tea capsules, etc. The brewing conditions of various capsules are different. The detection device 2 of Embodiment 1 can detect whether there is a capsule in the capsule compartment, but cannot detect the type of capsule, so the capsule brewing machine 1 can only manually select the brewing condition by the user and cannot handle it automatically. In view of this, this embodiment is improved on the basis of Embodiment 1, so that the capsule brewing machine 1 can identify the type of capsule, and thus adopt different brewing conditions or perform other different operations according to the type of capsule. Other parts of the capsule brewing machine 1 of this embodiment are the same as those of Embodiment 1 except for the detection device 2 .

[0059] The detection device 2 of this embodiment includes a detection source 21 , a driving component 23 and at least two sensing components 22 . ...

Embodiment 3

[0066] The capsule brewing machine in the above embodiment can automatically identify whether there is a capsule in the capsule compartment, but cannot determine whether the capsule is an unused capsule or a used empty capsule. Because beverage capsules are generally made of thin metal or plastic, they may be damp or leak due to rupture before brewing. The contents of normal capsules are powdery or fine-grained, and the contents of damp capsules usually freeze. blocks, into larger blocks. The above-described embodiment cannot identify such capsules that are not suitable for reconstitution due to moisture or leakage. This embodiment provides a capsule brewing machine in which the detection device 2 includes an ultrasonic emitting part and a photoelectric sensing part, which can identify the state of the capsule.

[0067] Figure 9 It is a schematic structural diagram of the detection device of this embodiment. Such as Figure 9 As shown, the detection device in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com