A new-type airfryer

An air fryer, a new type of technology, is applied in the direction of roaster/barbecue grid, kitchen utensils, food oven, etc., and can solve the problems of affecting the frying effect, fire, and difficult discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing of description:

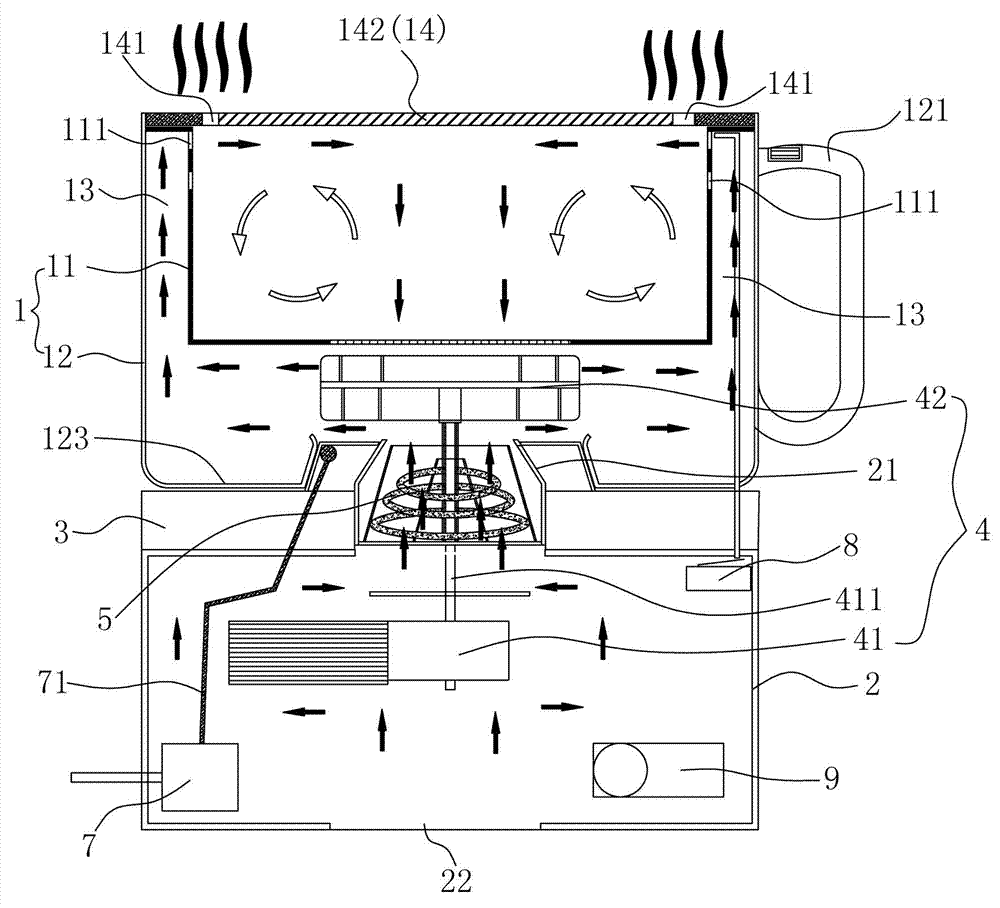

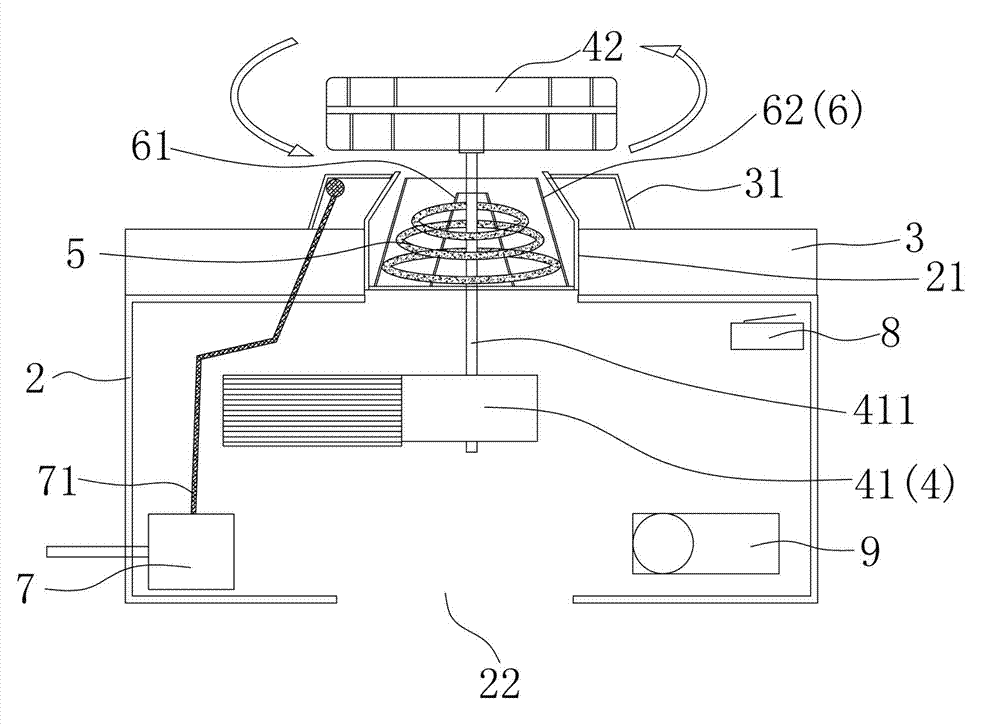

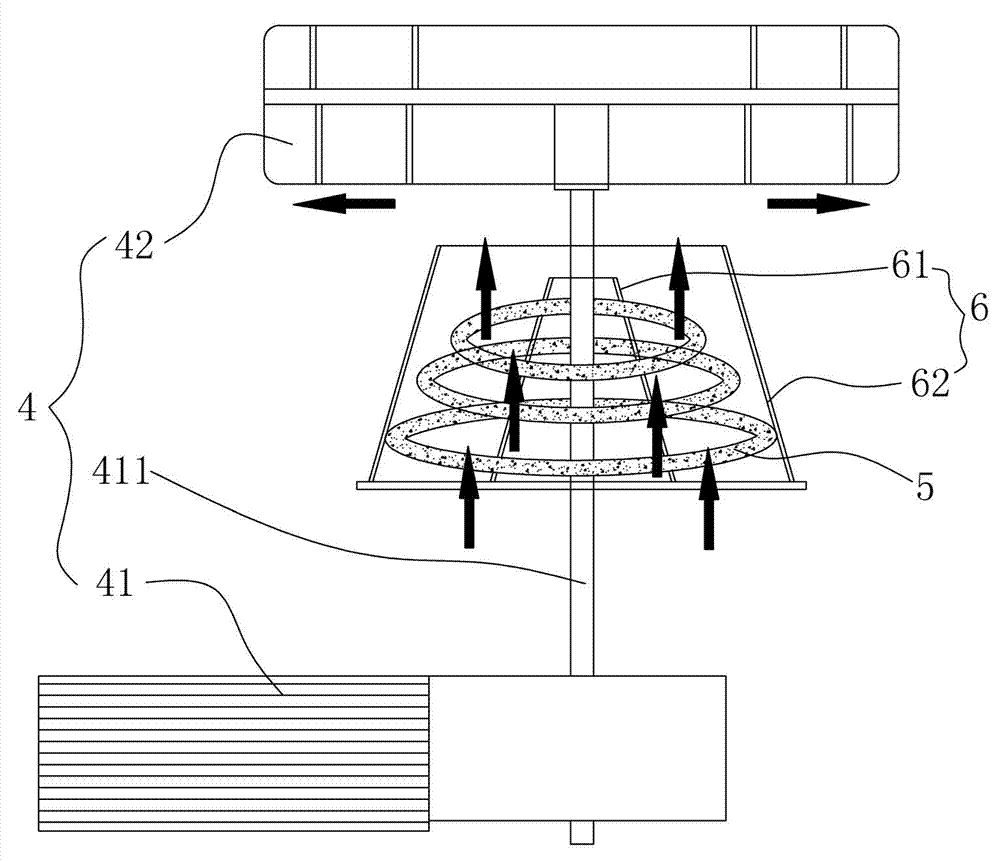

[0023] like Figure 1-4 As shown, the present invention relates to a novel air fryer, which includes a pot body 1 and a machine base 2 .

[0024] like figure 1 , 4 As shown, the pot body 1 is composed of an inner pot 11 and an outer pot 12 sheathed on the outside of the inner pot 11. The inner pot 11 is used to hold ingredients to be cooked. Both the inner pot 11 and the outer pot 12 have an open structure. The inner pot A gap 13 is formed between the 11 and the outer pot 12, and the gap 13 is used for hot air to enter the inner pot 11 from bottom to top, and a number of ventilation holes 111 are provided on the side wall and the bottom surface of the opening of the inner pot 11. The ventilation holes 111 of the inner pot 11 mutually form an air circulation channel, and hot air can pass through the gap 13, enter the interior of the inner pot 11 from the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com