Self-heating hot pot packaging box

A packaging box and self-heating technology, which is applied in the field of food packaging, can solve the problems of easy scald hands, slow speed, hot outer box, etc., and achieve the effects of increasing food cooking speed, reducing heat loss, and improving heat absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

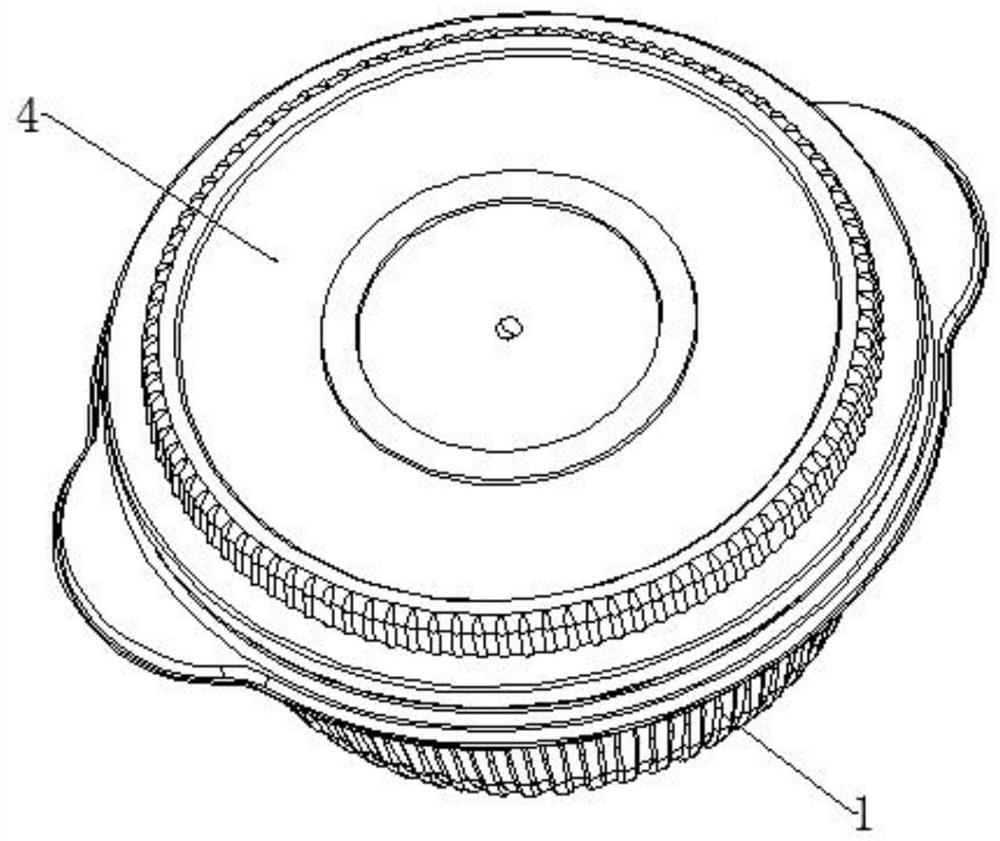

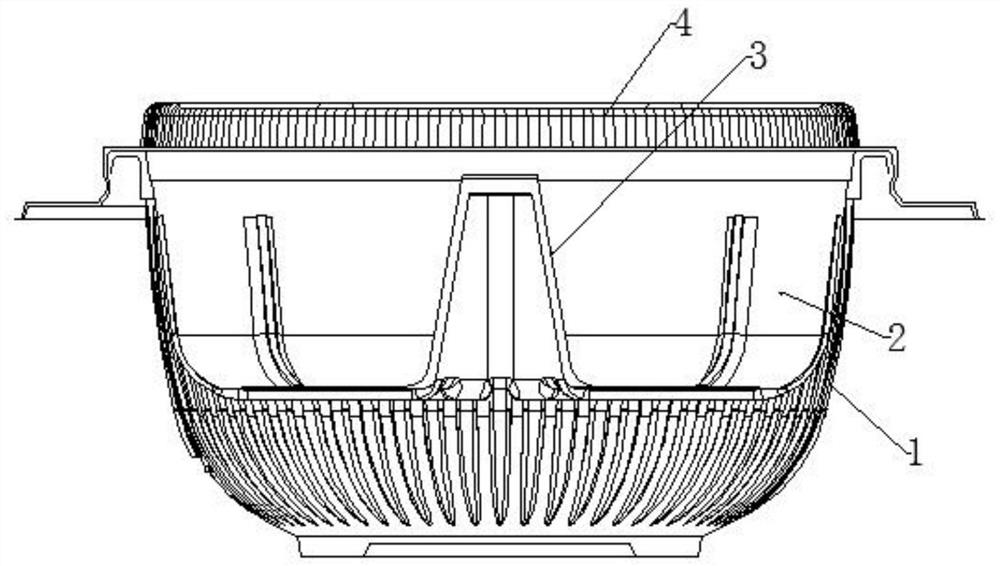

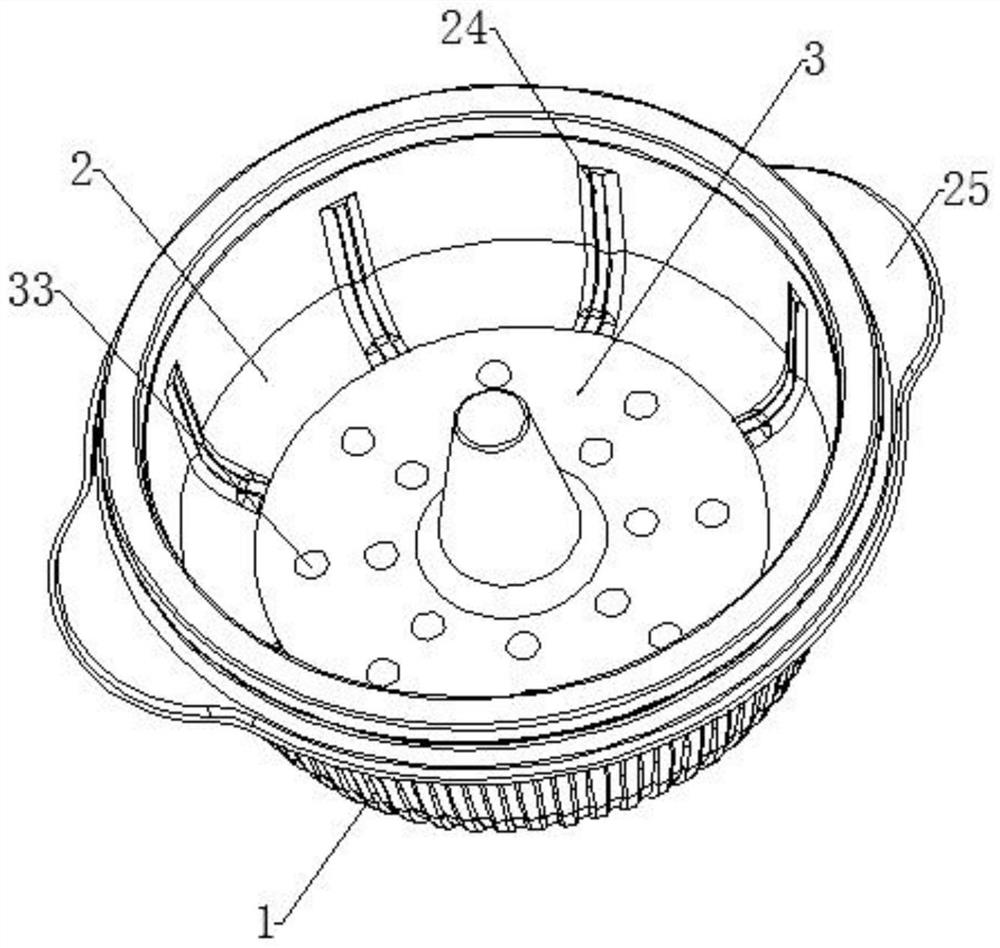

[0031]Such asFigure 1 - Figure 9As shown, a self-heating pot box, including the outer casing 1, the cover body 4, the upper edge of the outer casing 1, and the outer casing 2 is placed inside the outer casing 2, the inner casing 2 side wall The inner cavity protrusion is formed with a plurality of reinforcing ribs 24, and the inner casing 2 is integrally formed with a conductive column 21, and an exhaust gas hole 23 is opened at the top of the guide post 21. The air conductive column 21 is nested. The cover 3, and the inner casing 2 is tightly fitted with a cap 4.

[0032]In the present embodiment, the guide cover 3 includes a flat plate 32 which is placed in the bottom of the inner casing 2, and the flat plate 32 is placed on the upper surface of the reinforcing rib 24 in the inner casing 2, and the flat plate 32 is formed at the bottom of the inner casing 2. The gap is convenient for hot air flow, and the plate 32 is formed with a tapered cap 31, and the tapered cap 31 cover is on th...

Embodiment 2

[0040]The contents of this embodiment are substantially the same as those of the first embodiment, and the difference is:

[0041]In the present embodiment, only one of the air exciors 3 is formed, and there are several tapered cap 31 on the air-shaped cover 3, and all the tapered caps 31 match all the guide posts 21, even in the inner casing 2. There are a plurality of guide column 21, or only one air exhaust hood 3 is placed, which is convenient to use.

[0042]The working principle of the present invention is: When used, first remove the cover body 4, put the water and food of the cooked food together into the inner casing 2, using water pressure and ingredients 3 pressure in the inner casing 2 At the bottom, the heating package is placed in the boss bottom in the bottom of the outer casing 1, and the water is poured into the water storage tank 12, so that the water is brought into the heat package, it is recommended to supply the water to the position of the injection line 11, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com