Single-phase electric furnace transformer

A single-phase electric furnace and transformer technology, applied in transformers, variable transformers, fixed transformers, etc., can solve the problems of less winding turns, low secondary voltage, etc., to reduce installation space, save space, and reduce material costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

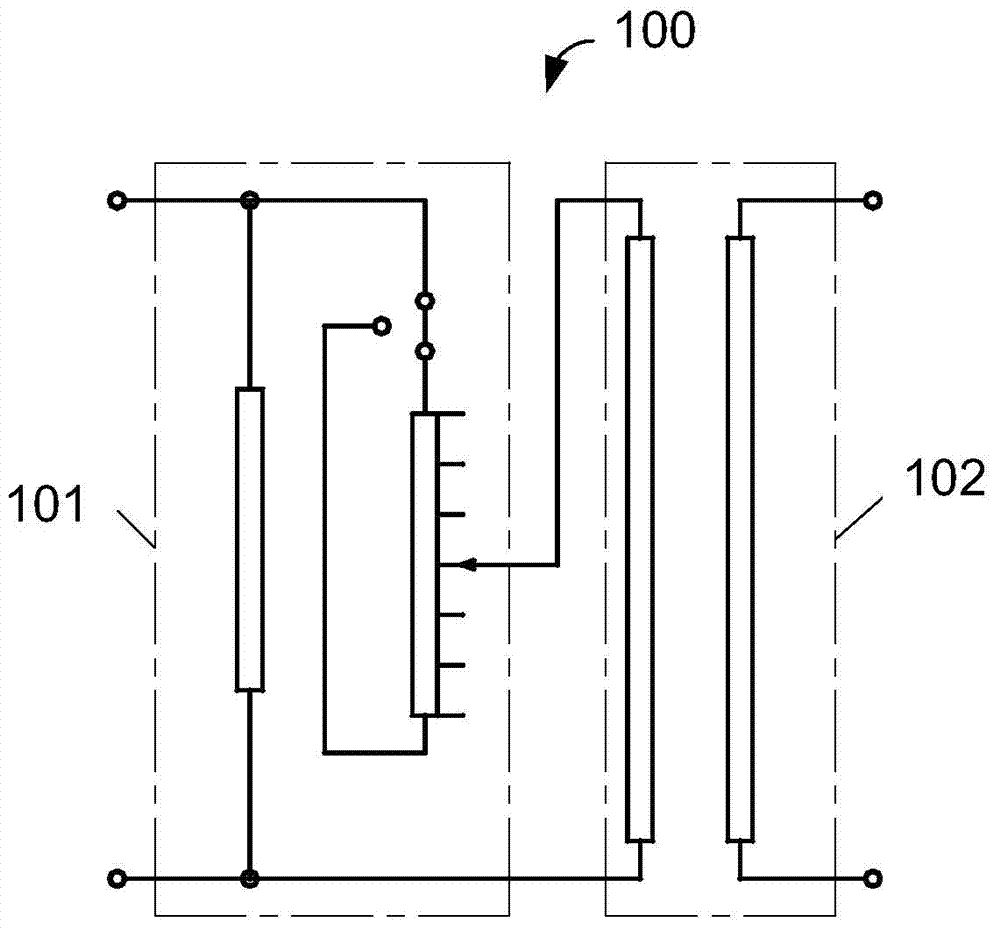

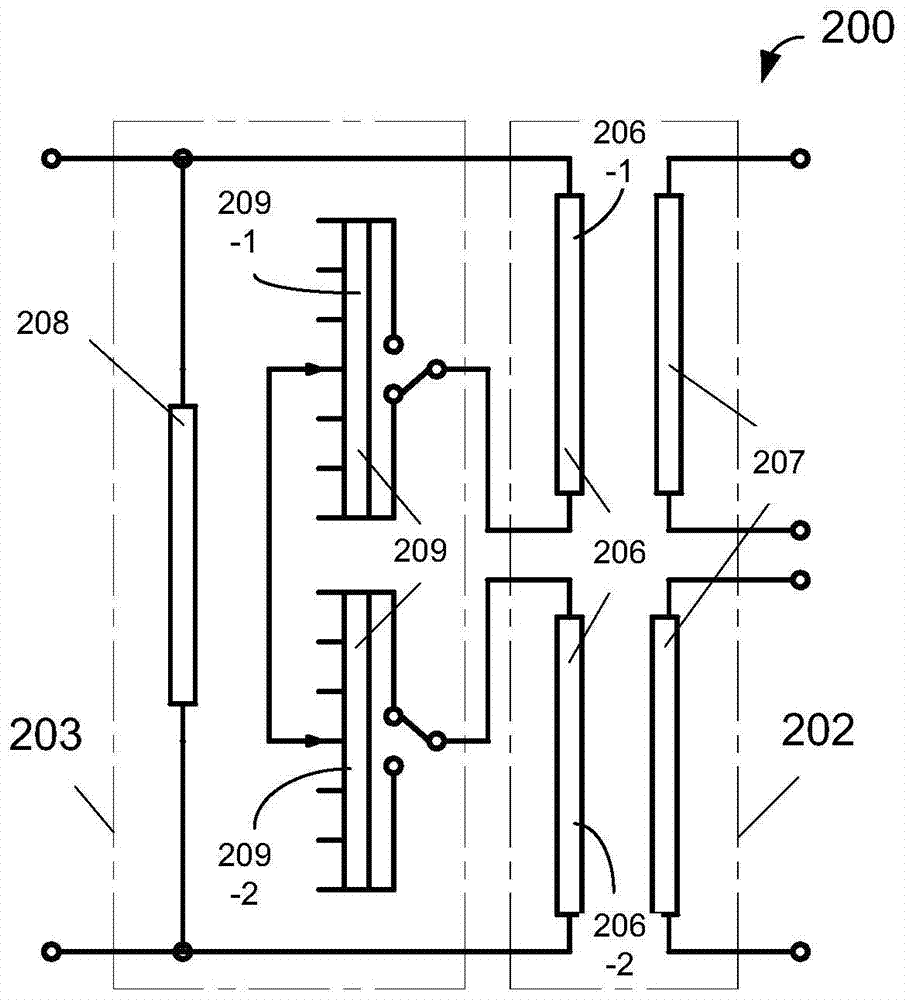

[0028] The following first reference Figure 2a ~ Figure 9 The basic principles of the present invention are discussed in detail. The single-phase electric furnace transformer 200 of the present invention mainly includes: a single magnetic core 201 , a main transformer 202 and a voltage regulating autotransformer 203 .

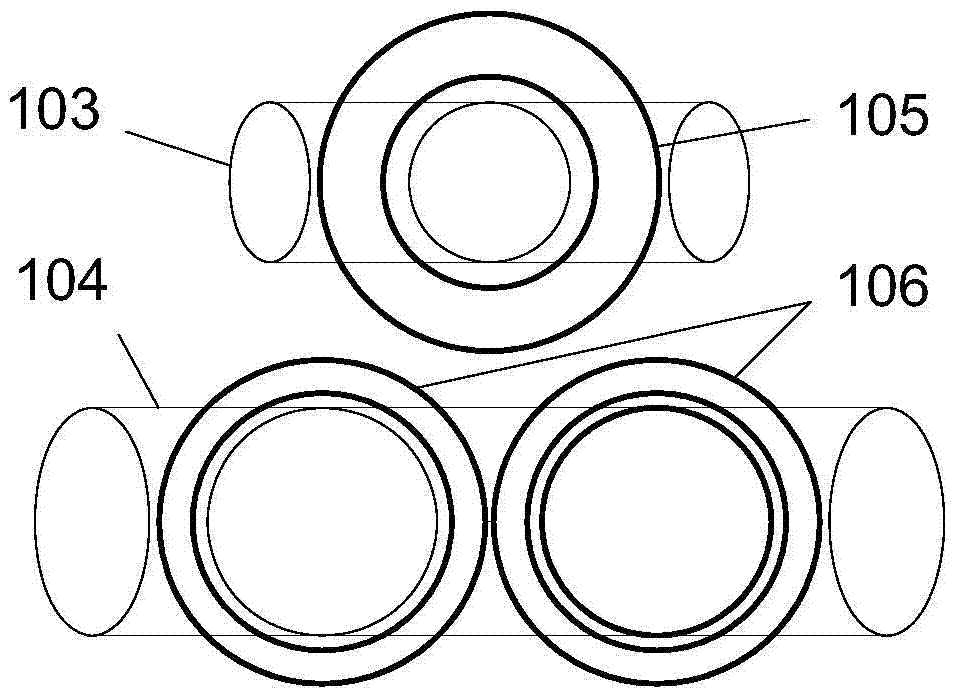

[0029] like Figure 2c As shown, the single magnetic core 201 has two side legs 204 and at least one main leg 205 (in Figure 2c There are two main stems in the illustrated embodiment, but an embodiment with only one main stem will be discussed further below). For example, the magnetic core 201 may be an iron core. The two side stems 204 are located on both sides of the main stem 205 .

[0030] back to Figure 2a , the main transformer 202 has a first primary winding 206 and a first secondary winding 207 arranged on at least one main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com