Inspection platform for live working tools

A technology for live work and tools, applied in the field of inspection platforms, can solve the problems of leakage inspection, large temperature difference, hidden dangers of live work safety production, etc., and achieve the effect of improving work efficiency, improving economic benefits, and reducing applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

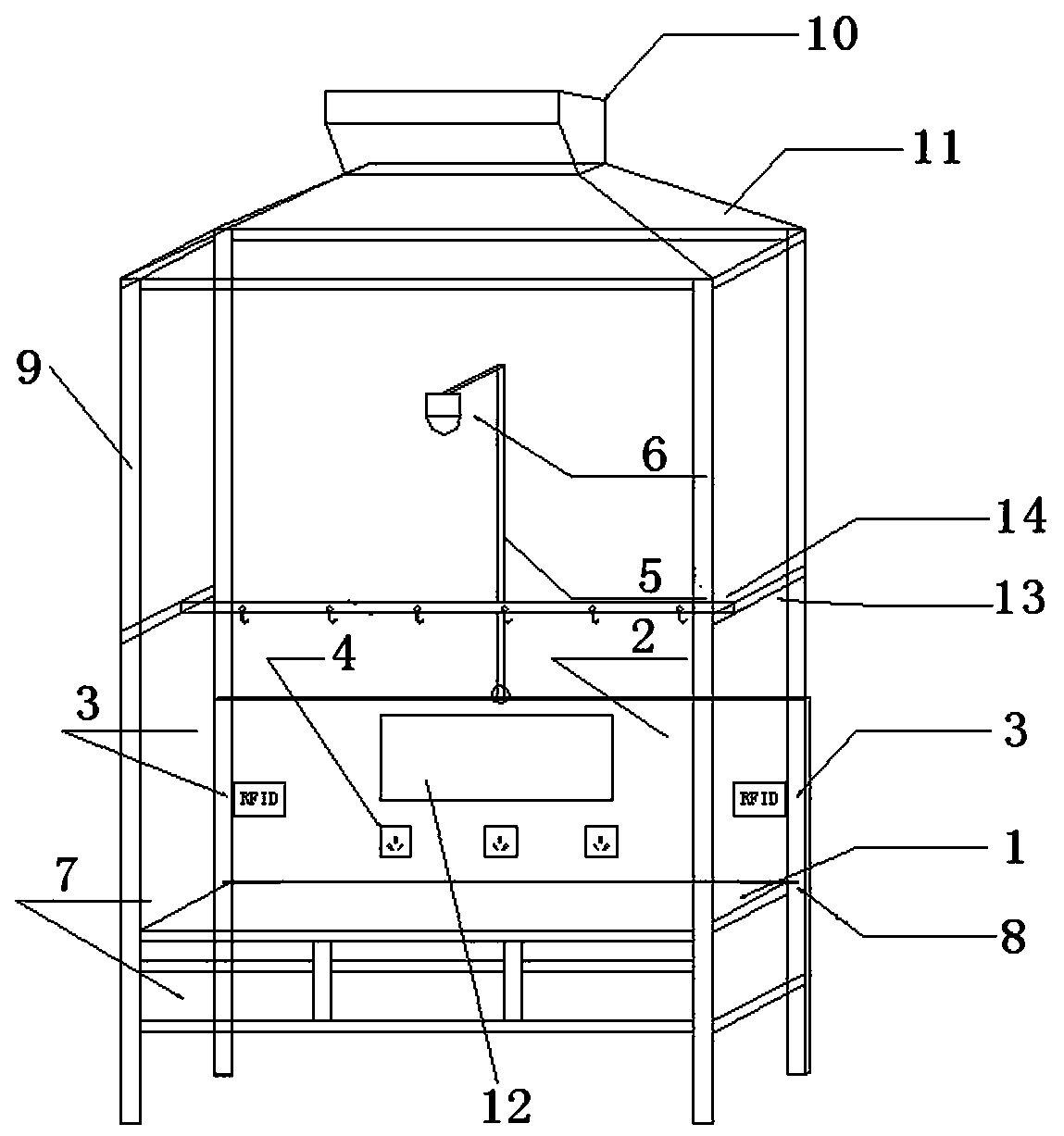

[0017] figure 1 It shows an embodiment of an inspection platform of a live working tool in the present invention, including an inspection operation platform 1 and an equipment fixing plate 2 vertically arranged on one side of the inspection operation platform 1, and the equipment fixing plate 2 RFID identification devices 3 are arranged on both sides of the horizontal plane, several power sockets 4 are arranged in the middle of the equipment fixing plate 2, and a video connecting rod 5 is also arranged on the upper end of the device fixing board 2, and a video device 6 is installed on the top of the video connecting rod 5 , the video device 6 is a video camera. The bottom of the inspection operation platform 1 is provided with several side-by-side instrument storage drawers 7, and the RFID identification equipment 3 is divided into RFID equipment A and RFID equipment B. After the electronic identity information of the identification tool, the two RFID equipment, RFID device A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com