OGS touch screen structure and manufacturing method

A production method and touch screen technology, applied to instruments, electrical digital data processing, and input/output process of data processing, etc., can solve problems such as broken and shorted silver wires, affecting silver wire printing yield, poor surface flatness, etc., to achieve The effect of improving yield rate, fewer layers, and improving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further clearly and completely described in conjunction with the accompanying drawings in the embodiments of the present invention, and the described embodiments are only some of the embodiments of the present invention, not all of them.

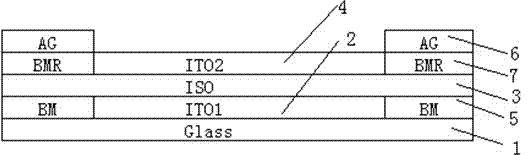

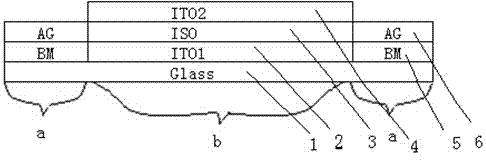

[0026] An OGS touch screen structure, including a glass substrate 1, a first conductive film layer 2, a black ink layer 5, an insulating layer 3, a silver wire circuit layer 6 and a second conductive film layer 4; the glass substrate 1 has a visible area b And be positioned at the frame area a of visible area b edge; Black ink layer 5 is printed on the frame area of glass substrate 1 surface; The first conductive film layer 2 is plated on the glass substrate 1 surface, and corresponding visible area; Insulation Layer 3 is arranged on the first conductive film layer 2 and corresponds to the visible area b; the second conductive film layer 4 is arranged on the insulating layer 3 and corresponds to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com